Custom Plastic Mold Maker Injection Parts LMK

Description

Basic Info.

Model NO. 8ET01

Surface Finish Process Heat Treatment

Mould Cavity Multi Cavity

Plastic Material PA66+GF

Process Combination Type Compound Die

Application Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Runner Hot Runner

Design Software AutoCAD

Installation Fixed

Certification TS16949, CE, ISO

Standard HASCO

Customized Customized

After-sales Service Yes

Product Material Plastic

Tolerance 0.02mm -0.05mm

Surface Finishing Texture/Sandy/Mt/Ys/Spi/EDM Finish/Smooth/Glossy

Drawing Format STP. Step . Igs . Prt . X_T

Transport Package Wooden Box

Trademark customized

Origin China

HS Code 8480410010

Production Capacity 500sets/Year

Product Description

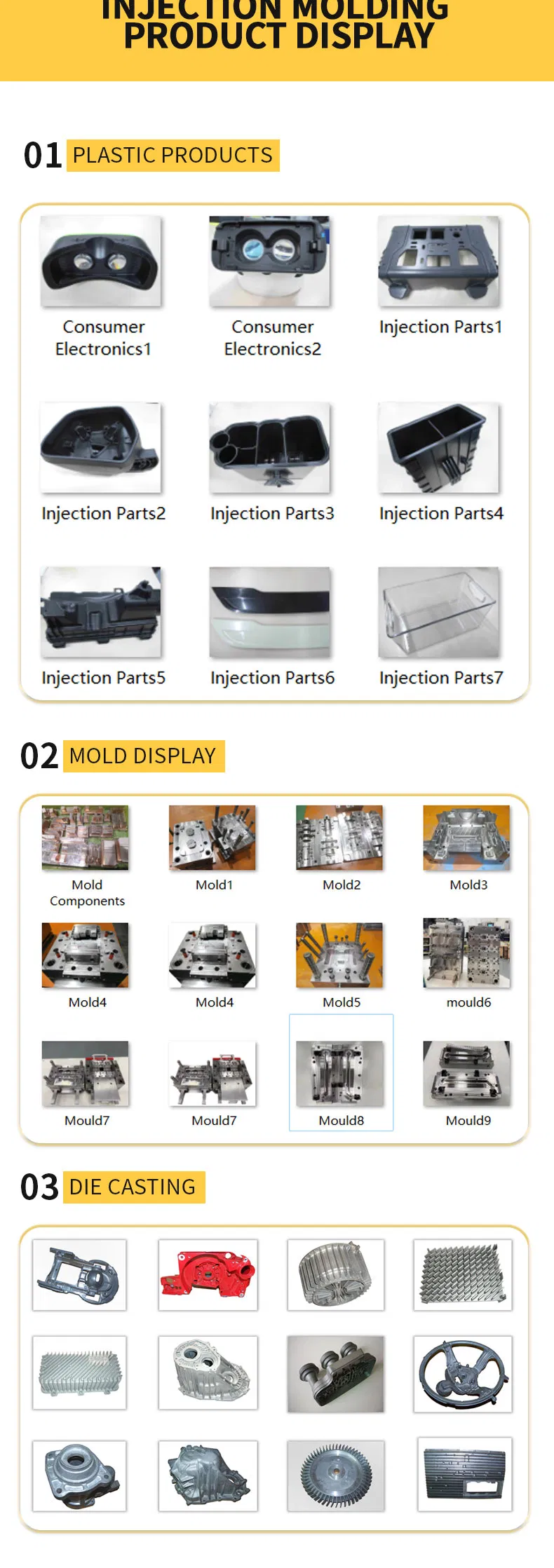

OEM ODM plastic injection molding

Plastic Materials

PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc.

Standard

ISO9001:2008

Quality

RoSH and SGS standard

Feature

Non marking and Non flash

Size

According to your 2D, 3D Drawing

Color,Quantity,Unit price,Tooling cost,Tooling size

To be discussed

Package

Standard exported Wooden box packed, Fumigation process(upon required)

Mold Building Lead Time

20~30 working days, Part measurement report (upon required).

Export Country

Europe, Japan, America, Australian, UK, Canada, France, Germany, Italy...etc.:

To be discussed

In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold Runner System, hot runner system mold...etc.

Mould Base

Hasco Standard, European Standard, World Standard,DEM standard,HUSKY standard...etc

Mould Base Material

LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirment

Surface Finish

Texture(MT standard), High gloss polishing,mirror polishing

Cavity/Core Steel

P20, 2311, H13, 2344, Starvax 420, 236, 738H, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc.

Mould Life

250,000 to 1,000,000 Shots. (According to your working environment.)

Design & Program Softwares

CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc.

Equipments

High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available.

1. Experience

Since the company was established in 2008, we have more than 15 years of experience in the field of mold manufacturing and plastic parts.

2. Design Ability

We have an excellent Design Team, 8 senior engineers work on different projects. We listen voice from our clients and give them good advice to make sure the production more economic and efficient, also makes the product more functional.

3. Good Communication

Communication is one of the most important factors in our cooperation. Our sales and engineers can best grasp the demands of customers, understand their intentions, and provide the best products to them.

4. One Stop Service

- Precision and Large Mold

- Hot Runner System Mold

- Over Mold

- 2K Mold/ Double Shot Mold

- Unscrew Mold

- Rapid & Prototype Mold

- Die Casting

- Plastic Molding

- One stop service for simples to complex parts from the design phase to mass production

5. Quality Control

Our quality control includes IQC(incoming quality control), PQC(production quality control) and FQC(final quality control). With QC report for every batch of production, all production data is recorded in our ERP system.

6. Fast delivery

We do plan and time table for projects, so it's no need to worry about delivery, also We have ability to handle urgent orders.

${currentPro.title}