Plastic Injection Mould for Disposable Cutlery

Description

Overview

| Model NO. | KL36192 |

| Surface Finish Process | Polishing |

| Mould Cavity | Single Cavity |

| Plastic Material | HDPE |

| Process Combination Type | Progressive Die |

| Application | Household Appliances, Furniture, Commodity, Home Use, Transportation |

| Runner | Hot Runner/Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | CE, ISO |

| Standard | DME |

| Customized | Customized |

| After-sales Service | Technical Guidance |

| Mould Name | Plastic Stool Mould |

| Processing | High Precision Tooling Machine |

| Delivery | 35 days |

| Color | Customized |

| Transport Package | Wooden Case |

| Specification | Customized |

| Trademark | Kelong Mould |

| Origin | China |

| HS Code | 8480719090 |

| Production Capacity | 150 sets/Years |

Packaging & Delivery

| Package Size | 20.00cm * 10.00cm * 5.00cm |

| Package Gross Weight | 3.000kg |

Product Description

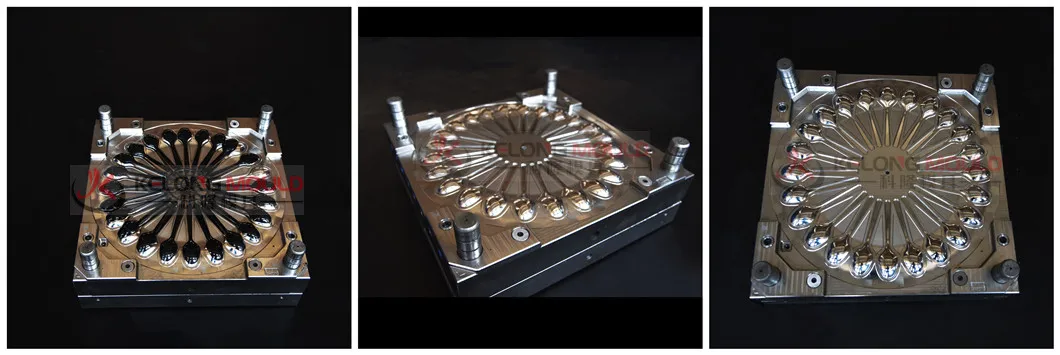

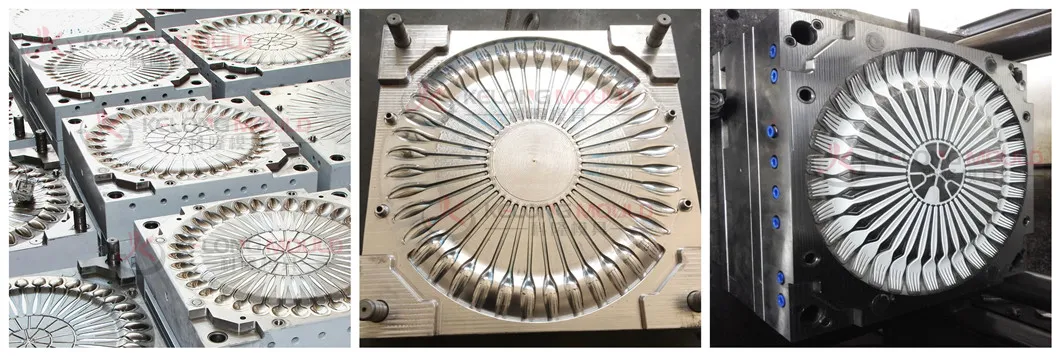

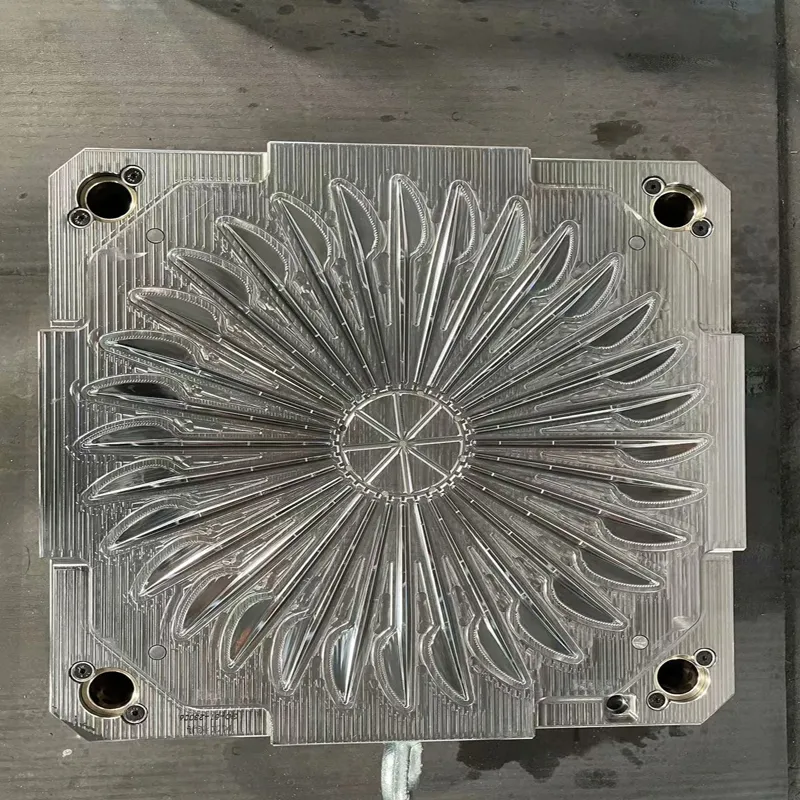

Plastic Injection Mould for Disposable Cutlery Spoon Fork Knife Moulds

Kelong Mould is a highly reputable and experienced manufacturer of plastic injection molds, specializing in a wide range of products including household molds, furniture molds, and industrial molds. With a commitment to quality, precision, and innovation, we have become a trusted partner for clients worldwide.

Our portfolio includes a diverse range of molds such as chair molds, table molds, bucket molds, basket molds, dustbin molds, storage box molds, baby bathtub molds, flowerpot molds, crate molds, washbasin molds, drawer molds, stool molds, baby set molds, laundry basket molds, pallet molds, trash can molds, spoon molds, knife molds, fork molds, thin wall box molds, and cap molds. Our team of highly skilled technicians and engineers is dedicated to designing and producing molds that meet the most demanding specifications.

Product Parameters

| Mould Name | Multi-Cavities Plastic Spoon Mold Injection Knife Tooling Plastic Fork Molds |

| Mold Material | P20, 2738, 718H, NAK80, 2316, S136, H13, etc. |

| Mold Base | Self-made, LKM, DME, ASSAB |

| Cavity | Single/multi |

| Runner | Cold runner and hot runner |

| Hot Runner Brand | INCO, HUSKY, YUDO and so on |

| Design Software | UG: Aoto CAD and so on |

| Mold Life | 50-500 million Shots / 5-6 years, Even in 10 years in good maintenance |

| T1 Time | 45-60 days |

| Plastic Material | PP PC ABS PET PE PVC PMMA TPR PA6, PA66, ASA, POM, PS, ABS, ABS+GF, ABS+PC, POM (Derlin) |

| Gate Type | Pinpoint Gate, Edge Gate, Sub Gate, Film Gate, Valve Gate, Open Gate, etc. |

| Mould Surface Treatment | EDM, texture, high gloss polishing |

| Quality System | ISO9001, SGS, TS16949 |

| HS Code | 8480719090 |

| Origin | Zhejiang China |

| Installation | fixed |

| Package | Wooden Case |

Mould QC

Our QC team will make all their efforts by "Scheme + supervise + prevent + transmit", to be sure that each project comes to successful completion.

- Mould design control: Kelong can provide product analysis and Mouldflow reports, will feedback to customers about the issue arising on the product drawing, such as the Thin thickness area, shrinkage mark, welting mark, Air vent, undercuts, gate location, gate type, etc. After the design is finished, we'll check on the Mould strength, part line, cooling system, interference area, Thin thickness area, etc. To be sure the drawing provided by Kelong is in excellent status for the longer mould life and work efficiency for customers.

- Mould material control: Steel suppliers are requested to provide steel quality guarantee certificate and steel certificate, Kelong will do steel inspection before acceptance.

- Mould Processing quality control: Controlling key procedure quality and managing the project progress according to mold processing documents, we provide weekly progress and quality report to customers. The mould technician is required to check the Mold appearance, cooling system, mold assemble, process procedures carefully according to Kelong standard and customers standards.

- Mould spare parts purchasing and control: We'll focus on qualified spare parts to meet customer requirements on standard parts models, standard quality and needed purchase time.

- Mould assembly control: Physical processing will be undertaken as per the established procedure documents and be inspected relatively, strictly checking on the matching between core, cavity, inserts, guide pillar, return pin, angle lifter, sliders, ejector pin, cooling system, connector, etc.

- Mould check before shipment: Prepare documents before shipment, such as spare parts list, mold testing video, processing files, 2D/3D drawings. For sure we'll pack and ship as per customers' requirements with safety protection for sea and air shipment.

Recommended Products

OUR MAIN PRODUCTS

click the pictures for more products

${currentPro.title}