Manganese Wear Parts for Cone Crushers

Description

Basic Info.

| Model NO. | Bushing Bronze |

| Certification | ISO 9001:2008 |

| Standard | ASTM |

| Surface Treatment | Polishing |

| Manufacturing Process | Casting |

| Material | Copper |

| Application | Quarry |

| Use | Ore Mining |

| Sample Order | Available |

| Color | Request |

| Usage | Crushing etc |

| Size | Full Types |

| Advantage | Wear Resistant |

| After Services | Available |

| Drawing | Original |

| Guarantee | Same as Original |

| Transport Package | Wooden Box |

| Specification | cone crusher parts |

| Trademark | SLon |

| Origin | Jinhua Zhejiang |

| HS Code | 8474900000 |

| Production Capacity | 500 Pieces/Month |

Product Description

Product Name: Cone crusher parts / Bushing / Bronze Bushing / Eccentric Bushing

Applications: Widely used in mining industry, metallurgical industry, construction industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone and so on.

Product Benefits: Compared with the general market products, our products have smooth surface, accurate dimensions, high wear resistance and longer life. Direct sales by the company foundry, cost-effective products.

Main Features:

- Competitive products: Good quality with reasonable price

- Material: High manganese and customised materials

- Use: We can supply almost crusher parts

- Quality: ISO9001 & TS and CE certification

The double times harding processing technology of high manganese steel. The product Used life can be increased more than 30%

Products Exhibition:

We can provide large batches:

- Terex

- Telsmith

- Kue-Ken (Brown Lenox)

- Powerscreen Maxtrak

- Terex Pegson Maxtrak

- Extec X SBS

- Pegson

- CH420

- HP100

- GP100S

- RC36

- 24"

- 2'

- CT28"

- 1000

- TC1000

- X38

- 700

- H22"

- CH430

- HP200

- GP200S

- RC45

- 36"

- 3'

- CT750

- 1000SR

- WC1000

- X4

- 900

- H200

- CH440

- HP300

- GP300S

- RC45-II

- 38"

- 4'

- CT36"

- 1300

- 1000SR

- 1000

- H2000

- CH660

- HP400

- GP500S

- RC54

- 44"

- 4800 4¼ '

- CT40"

- 1500

- TC1300

- 1300

- H36"

- CH870

- HP500

- GP100

- RC54-II

- 48"

- 5100 5½ '

- CT51"

- 1500

- WC1300

- 1500

- H45"

- CH880 (H8800)

- HP700

- GP200

- RC60

- 52"

- 7'

- CT51"

- 1500

- 1500

- H4000

- CH890

- HP800

- GP300

- RC66

- 66"

- 36"

- CT130

- 1500

- 1500

- H4000

- CH895

- HP3

- GP550

- RC45III

- 48"

- CT130

- 1500

- 1500

- H6000

- CS420 (S2800)

- HP4

- GP11

- MVP280

- 66"

- CT130

- 1500

- 1500

- H8000

- CS430 (S3800)

- HP5

- G49

- MVP380

- 36"

- CT130

- 1500

- 1500

- S36"

- CS440 (S4800)

- HP8

- G108

- MVP450

- 36"

- CT130

- 1500

- 1500

- S2000

- CS660 (S6800)

- MP800

- G412

- MVP550

- 36"

- CT130

- 1500

- 1500

- S3000

- CS820 (S8800)

- MP1000

- G612

- MVP550

- 36"

- CT130

- 1500

- 1500

- S4000

Packaging & Shipping

Shipping: By Container.

Company Information

WuYi Slon Machinery Co;Ltd is a professional manufacturer in wear parts. At Wear and Spare Parts we offer an extensive range of crusher wear parts for all jaw, cone and impact crushers of those Chinese Brand or Foreign Brand. All of our crusher wear parts are of the highest specification and are continuously tested globally to make sure they are of premium quality. Wear and Spare Parts offer all hammers, track shoe and blow bars, as well as extensive range of liner plates for all impact crushers on the market, meaning that for all your crusher wear part requirements, Wear and Spare parts offer a first class service to all our Global Customers.

FAQ

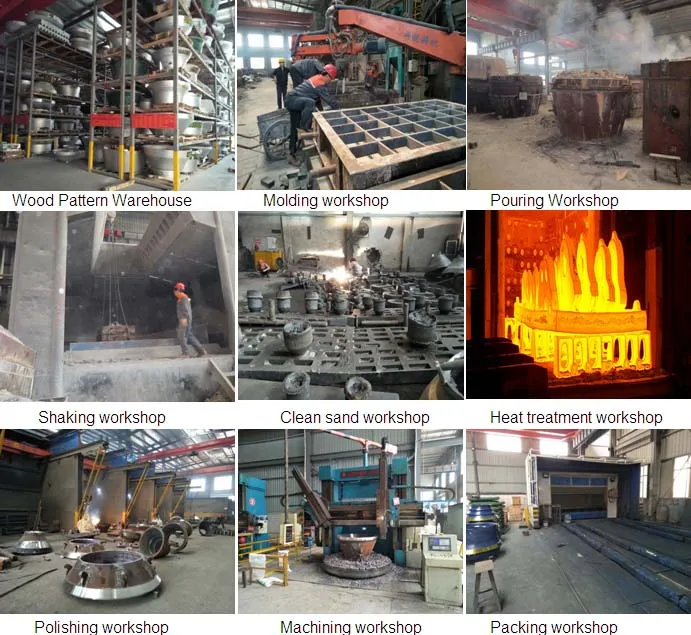

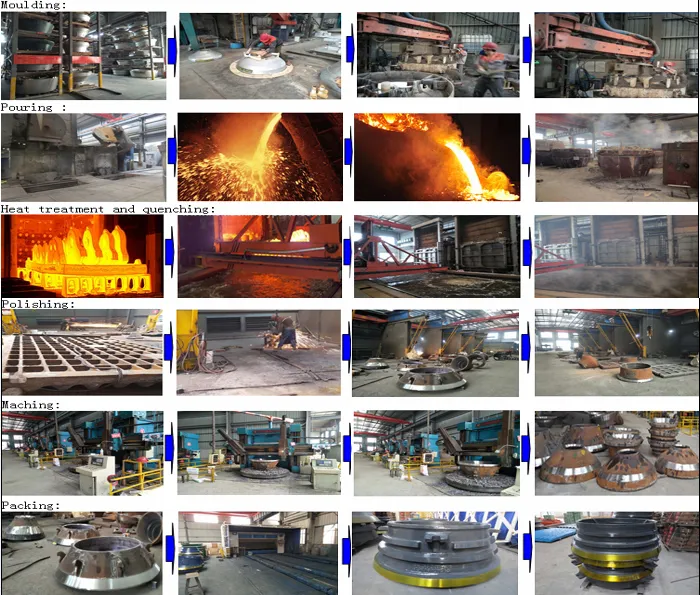

Production process:

- 1. Q: What kinds of products do you offer?

- A: SLon Machinery provided parts are mainly related to your machine. It ranges from the drill rod, excavator buckets and wheel loaders, crusher spare parts, construction machinery parts, brass bush, conveyor and screen spare parts, beneficial equipment spare parts, grinding mill spare parts, machining spare parts and other customized spare parts.

- 2. Q: What kind of materials are you familiar with?

- A: We are familiar with carbon steel, alloy steel, standard wearing plate, high material steel, high chrome steel, casting iron, and bronze. We have begun to research ceramic insert material technology.

- 3. Q: Can you use foundry machining castings ?

- A: Yes, the CNC machine can machine material hardness from HB200 to HRC62. The maximum machining length is 8m and maximum width is 4m.

- 4. Q: What information do we need to provide to you in order to confirm our parts order?

- A: We work with technical drawings for any non-standard products. If the order is for standard parts, you only have to provide us with the part number so we may define the parts of the order.

- 5. Q: Would you like to accept factory inspection?

- A: We are greatly welcome to our factory for your inspection.

- 6. Q: Why you have to choose us from multiple vendors?

- A: We have an increasing presence in the global market for more than 15 years - Reputation.

- 7. Q: How do you judge sufficient components for our parts?

- A: As long as the material is chosen, we shall strictly manufacture the parts according to standard.

- 8. Q: Except for your products, do you offer some other services or new business opportunities?

- A: Yes, we provide lots of service to you as you can see on our service. Slon Machinery has lot of new ideas for working with you and keeping your business moving forward.

${currentPro.title}