Ground Solar Energy Bracket PV Ground Mounting System with Ground Screw

Description

Overview

Basic Info.

- Model NO. Solar Ground Mounting System

- Certification ISO, CE

- Application Home, Industrial, Commercial

- Specification Normal, AS PER CLIENT REQUIRED

- Modelnumber Solar Ground Mounting System

- Selling Units Single Item

- Service Life 25yrs

- Single Gross Weight 10.000kg

- Advantages Customized Service Provided

- Color Silver

- Wind Load 60m/S

- Material Q355b Steel

- Engineering Service Engineering Service

- Mounting Type Ground Solar Mounting System

- Product Name Solar Ground Mounting System

- Surface Treatment Hot-DIP Galvanized

- Single Package Size 20X10X2cm

- Our Service Professional Customization Services

- Certificate CE/ISO9001

- Transport Package Export Standard Package

- Trademark Jiudingli

- Origin Shandong, China

- HS Code 73089000

- Production Capacity 360000t/Year

Packaging & Delivery

- Package Size 100.00cm * 50.00cm * 50.00cm

- Package Gross Weight 5.000kg

Product Description

Solar Racking System Adjustable Solar Panel Mount Structure Solar Panel Roof Mount Brackets

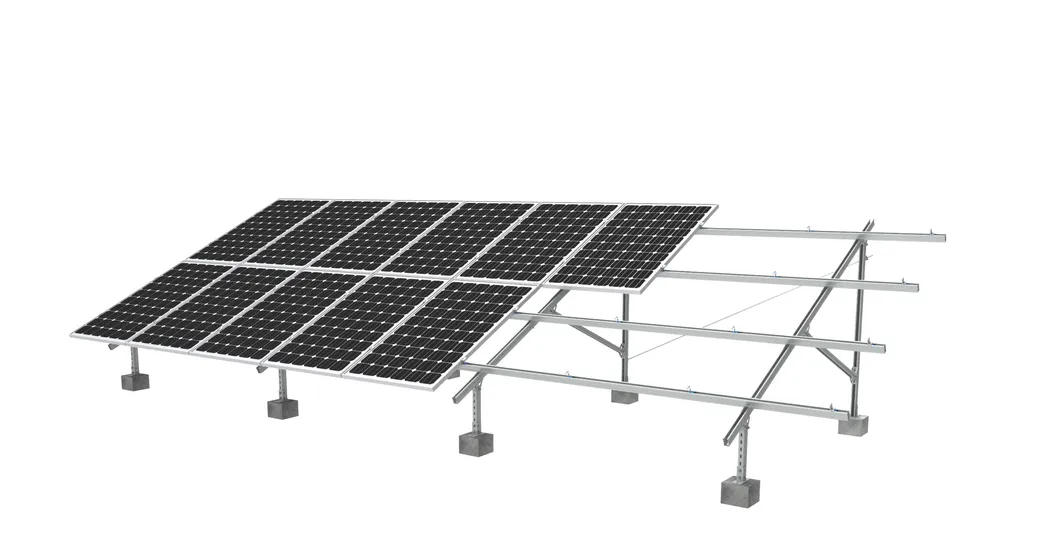

Solar Ground Mounting System

The structure of photovoltaic support usually includes columns, main beams, purlins, welds and foundation components. It can be customized according to different sizes and shapes of photovoltaic modules to meet the installation needs of different environments. There are a wide variety of materials available for photovoltaic brackets, including aluminum alloys, hot dip galvanized and zinc-aluminum-magnesium. The selection of these materials usually depends on the local climatic conditions and geological characteristics.

The main categories of photovoltaic brackets include fixed brackets and tracking brackets. The fixed bracket is divided into two kinds of fixed brackets that can be adjusted and cannot be adjusted. The fixed photovoltaic bracket is divided into single column bracket and double column bracket. The tracking bracket can be automatically adjusted mechanically or electronically to track the movement of the sun. The tracking brackets are available in flat single-axis tracking, oblique single-axis tracking and two-axis tracking brackets that can be adjusted in multiple directions to capture solar energy more efficiently.

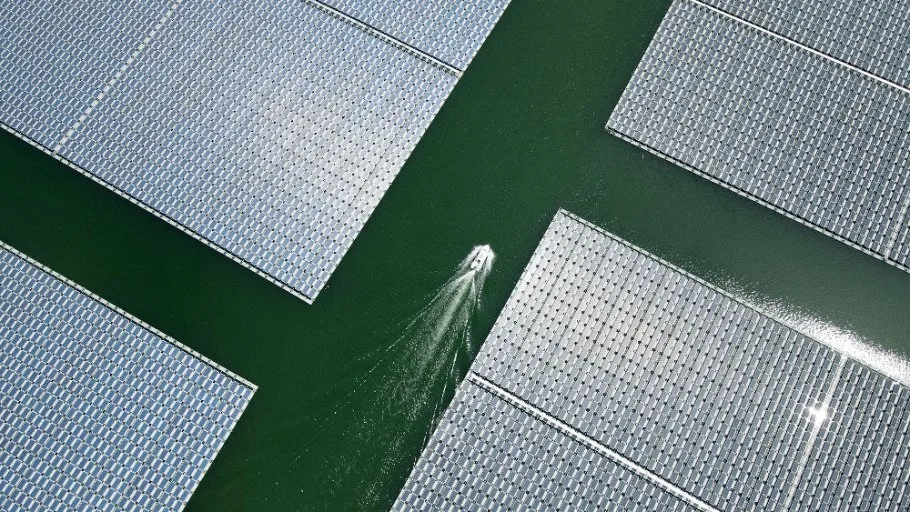

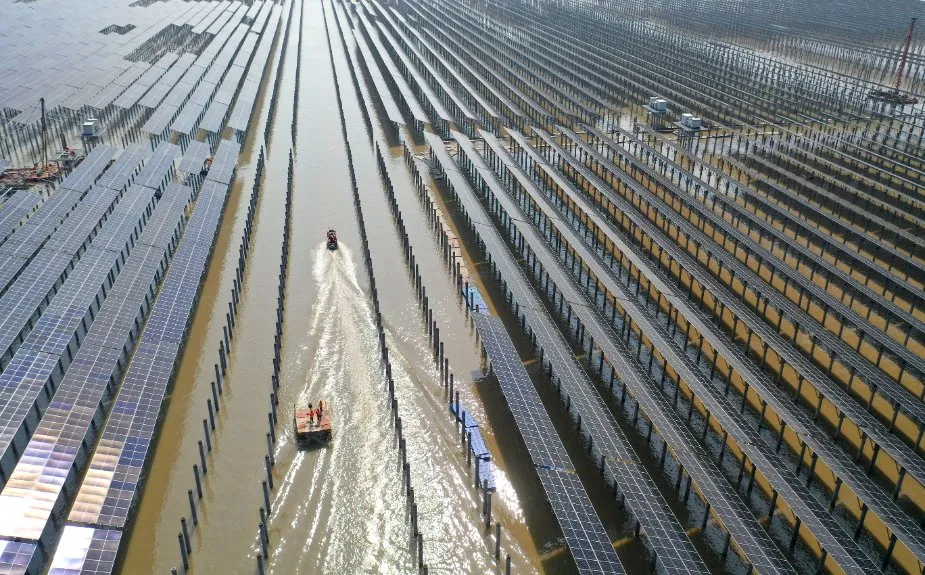

Photovoltaic brackets have a wide range of application scenarios and can be installed on the ground or in other specific environments.

Product name

Solar Ground Mounting System

Applicable area

Flat land, gentle slope, marsh, farm

Certificate

CE/ISO9001

Tilt Angle

0 to 70 °

Service life

25YRS

Pile foundation form

Driven pile/cast-in-place pile/cement foundation/screw pile

Our Service and Advantages

Professional Customization Services

Details Images

Our Advantages

Solar Ground Mounting System--The fixed photovoltaic bracket

- High stability The fixed photovoltaic bracket uses a robust structural design, which can maintain stability under various climatic conditions and reliably support photovoltaic modules.

- Low maintenance cost The fixed photovoltaic bracket has no moving parts, simple structure, relatively convenient production and installation, so the maintenance cost is relatively low.

- Wide applicability The fixed photovoltaic bracket is suitable for a variety of sites, including roofs, ground, hillsides, etc. Whether it is urban or rural, the fixed photovoltaic bracket can be flexibly applied.

- Long life The service life of the fixed photovoltaic bracket is long, generally reaching more than 30 years.

Solar Panel Mounts

Solar Panel Brackets

Solar Ground Mounting System--Adjustable Solar Ground Mounting System

- Adjustable Angle The photovoltaic panel adjusting bracket usually supports manual or automatic Angle adjustment, which can make the photovoltaic panel always perpendicular to the sun and improve power generation efficiency.

- Good stability The photovoltaic panel adjusting bracket is generally made of aluminum alloy, stainless steel and other materials, with stable structure, strong corrosion resistance, and stable support for photovoltaic panels.

- Be flexible The photovoltaic panel adjusting bracket can be flexibly arranged and is not limited by terrain.

- Easy maintenance

Automatic Tracking Solar Bracket

Adjustable Solar Brackets

The structure, classification and application of photovoltaic support:

The structure of photovoltaic support usually includes columns, main beams, purlins, welding parts and foundation components. They can be customized according to the different sizes and shapes of photovoltaic modules to meet the installation needs of different environments. There is a wide variety of materials available for photovoltaic supports, including but not limited to aluminum alloy, steel and concrete. The selection of these materials usually depends on the local climatic conditions and geological characteristics.

The main categories of photovoltaic brackets include fixed brackets and tracking brackets. The fixed bracket cannot be adjusted for Angle, while the tracking bracket can be automatically adjusted mechanically or electronically to track the sun's movement. In addition, there are special bracket types, such as single-axis and dual-axis tracking brackets, which can be adjusted in multiple directions for more efficient solar energy capture.

Photovoltaic supports have a wide range of application scenarios, which can be used on the roof of a building, or installed on the ground or in other specific environments. They are not only suitable for domestic and commercial photovoltaic power plants, but also for special applications in agricultural photovoltaic systems, maritime and highway lighting. With the advancement of technology, the design of photovoltaic brackets is also constantly optimized to improve its performance and economy.

Installation Instructions

The installation of bracket and components

- Installation of fixed solar panels The installation of solar panels should be carried out from the bottom up, step by step, and be horizontal and vertical, the spacing of panels in the same side should be consistent, and attention should also be paid to the direction of panel wiring. When the panel is fixed, the component is fixed on the chain with bolts in the steel structure, and the double thorn gasket is added between the panel and the guide rail. After the middle fixture and the side fixture are set, the nut is locked.

- Panel connection Determine the connection mode of the panel according to the design drawing, and pay attention not to reverse the positive and negative terminals when wiring to ensure that the wiring is correct. After each panel is connected, check whether the panel string break voltage is correct. After connecting, disconnect the line on the panel and carry out the subsequent process operation.

Main Products

FAQ

Q: How to pay?

A: T/T - 30% deposit in advance, 70% balance before shipment. Or L/C At sight.

Q: What is the delivery time?

A: Generally speaking, the delivery time will be within 15 - 35 days.

Q: How about your quality control?

A: We have our own professional quality control team with rich experience and advanced inspection equipment. Also we are willing to accept any other the third inspection part to control.

Q: How to install?

A: We will provide detailed instruction photos and videos to you. If it is necessary, we will send professional engineers to do the construction guidance, and some skilled workers to help installation. However, the visa fee, air tickets, accommodation, wages will be borne by buyers.

${currentPro.title}