EN

Language

All categories

Product ID: 68651920

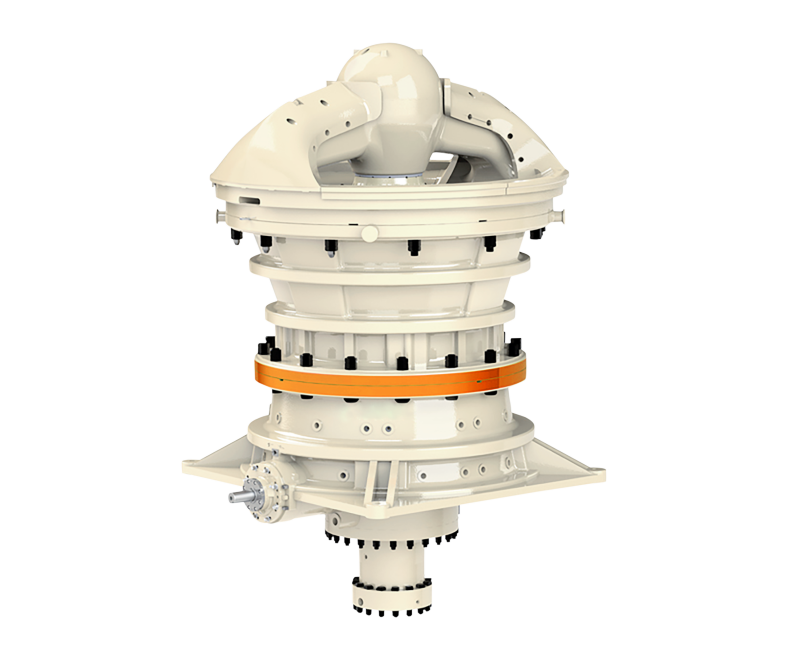

the GC5065 Gyratory Crusher

Contact Now

Description

GC Series Gyratory Crusher: A Reliable Solution for Industrial Crushing Needs The GC Series Gyratory Crusher is a high-performance and durable crushing equipment designed to meet the demanding requirements of various industrial applications. As part of the GC Series, this machine offers an efficient and cost-effective solution for processing a wide range of materials, including ores, rocks, and other hard substances. Whether you are looking for a Gyratory Crusher for Sale or considering integrating a Gyratory Crusher System into your operations, the GC Series provides a robust and scalable option that ensures consistent performance and long-term reliability. Overview The GC Series Gyratory Crusher is engineered with advanced technology and precision manufacturing to deliver superior crushing efficiency and minimal maintenance requirements. This system is ideal for large-scale mining, aggregate production, and construction industries where high throughput and durability are essential. The Gyratory Crusher for Sale is available in multiple configurations to suit different operational needs, making it a versatile choice for businesses seeking reliable and high-quality crushing solutions. Key Features One of the standout features of the GC Series Gyratory Crusher is its advanced eccentric mechanism, which allows for smooth and continuous operation even under heavy loads. The design incorporates a sturdy frame and reinforced components to withstand the toughest conditions. Additionally, the crusher is equipped with an adjustable discharge opening, enabling operators to control the size of the final product according to specific requirements. The Gyratory Crusher System also includes a comprehensive safety mechanism to ensure safe and efficient operation in all environments. Another notable characteristic is the energy-efficient operation of the GC Series. By optimizing power consumption and reducing unnecessary wear on critical parts, the system helps lower overall operating costs while maintaining high productivity. The use of high-quality materials and precision engineering further enhances the longevity and performance of the machine, making it a valuable investment for any industry that relies on consistent and reliable crushing capabilities. Detailed Description The GC Series Gyratory Crusher operates by using a conical-shaped crushing chamber, where the material is subjected to both compression and shear forces. This dual-action process ensures that the material is efficiently broken down into smaller particles with minimal fines. The rotating motion of the main shaft, combined with the stationary concave, creates a powerful crushing action that can handle a variety of feed sizes and types. This system is designed to be user-friendly, with easy access to key components for maintenance and inspection. The modular design allows for quick and straightforward installation, while the integrated control system provides real-time monitoring and adjustments for optimal performance. The Gyratory Crusher for Sale comes with detailed documentation and support, ensuring that users can operate and maintain the equipment effectively. The GC Series Gyratory Crusher is also known for its adaptability. It can be customized with different types of liners and wear parts to match the specific properties of the material being processed. This flexibility makes it suitable for a wide range of applications, from primary to secondary crushing stages, depending on the operational setup. Use Cases The GC Series Gyratory Crusher is widely used in the mining and aggregate industries, where it plays a crucial role in the initial stage of material processing. It is particularly effective in handling large volumes of hard and abrasive materials, such as granite, basalt, and iron ore. The system's ability to produce a uniform particle size makes it ideal for applications requiring precise grading, such as road construction, concrete production, and sand manufacturing. In addition to mining, the Gyratory Crusher System is also employed in recycling facilities, where it helps break down construction debris and other solid waste materials. Its durability and efficiency make it a preferred choice for companies looking to reduce downtime and increase overall productivity. The versatility of the GC Series ensures that it can be adapted to fit various operational setups, whether in a small-scale plant or a large industrial complex. User Reviews Users who have implemented the GC Series Gyratory Crusher in their operations consistently praise its performance and reliability. Many highlight the machine's ability to handle tough materials without frequent breakdowns, which significantly reduces maintenance costs and downtime. One operator noted that the system has improved their production output by over 20%, thanks to its efficient crushing mechanism and ease of operation. Another user emphasized the value of the adjustable discharge opening, which allows them to tailor the final product size according to customer specifications. They also appreciated the energy-saving features, which have helped lower their electricity bills without compromising on performance. Overall, the feedback reflects a strong satisfaction with the GC Series Gyratory Crusher as a dependable and high-performing solution for industrial crushing needs. Frequently Asked Questions What materials can the GC Series Gyratory Crusher process? The GC Series Gyratory Crusher is designed to handle a wide range of hard and abrasive materials, including but not limited to ores, rocks, minerals, and construction waste. Its robust design allows it to process materials with high compressive strength efficiently. How does the Gyratory Crusher System contribute to productivity? The Gyratory Crusher System is engineered for high throughput and efficiency, allowing for continuous operation with minimal downtime. Its advanced design and adjustable features enable operators to optimize performance based on specific material and production requirements. Is the GC Series Gyratory Crusher easy to maintain? Yes, the GC Series Gyratory Crusher is designed with maintenance in mind. Key components are easily accessible, and the system includes a comprehensive safety mechanism to ensure safe and efficient maintenance procedures. Can the GC Series Gyratory Crusher be customized? Yes, the GC Series Gyratory Crusher can be customized with different wear parts and configurations to suit specific application needs. This adaptability ensures that the system can be tailored to match the unique requirements of each operation. What is the expected lifespan of the GC Series Gyratory Crusher? With proper maintenance and operation, the GC Series Gyratory Crusher can last for many years, providing consistent and reliable performance throughout its service life. The use of high-quality materials and precision engineering contributes to its long-lasting durability.

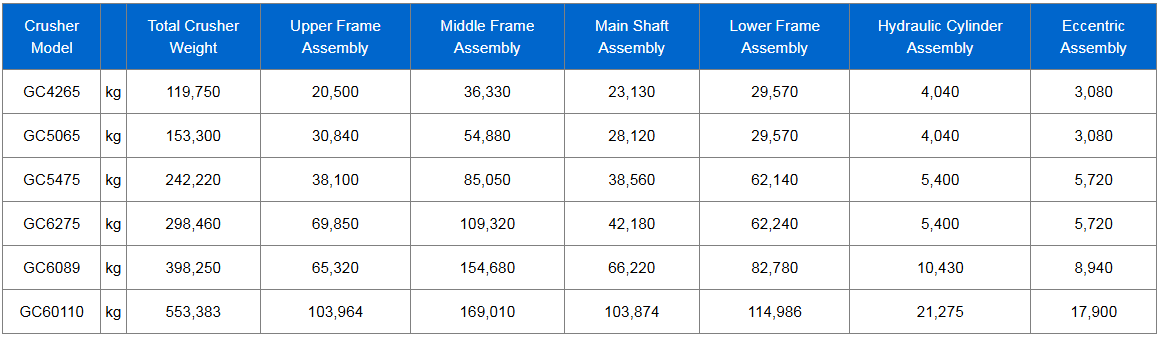

Technical Parameters:

The above capacities are based on assumed feed conditions where the maximum feed size is less than 0.8 times the feed opening; 80% of the feed is less than 0.6 times the feed opening; and 50% of the feed is less than 0.1 times the feed opening. These capacities apply to feed material with a bulk density of 1.6 tons per cubic meter.

All capacities are calculated based on the maximum throughput of each unit. All capacities are application-specific. Material characteristics, feed size and distribution, work index, moisture percentage, and feeding method are all factors when considering crusher capacity.

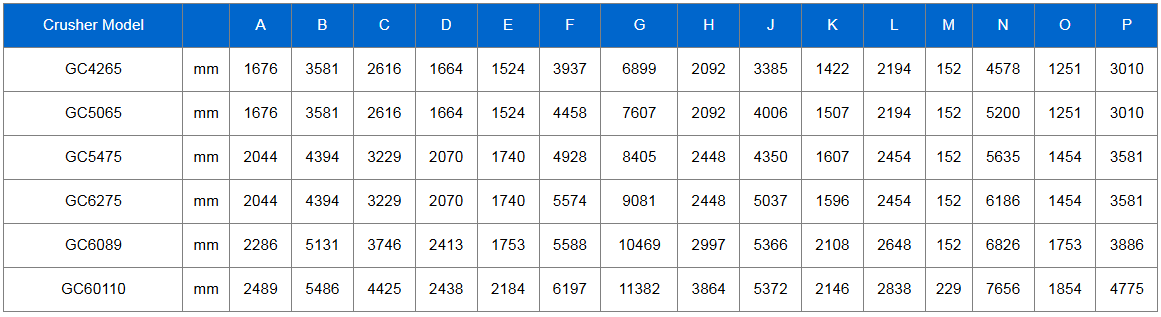

Overall Dimensions:

Contact Now

Please Send Message

${currentPro.title}