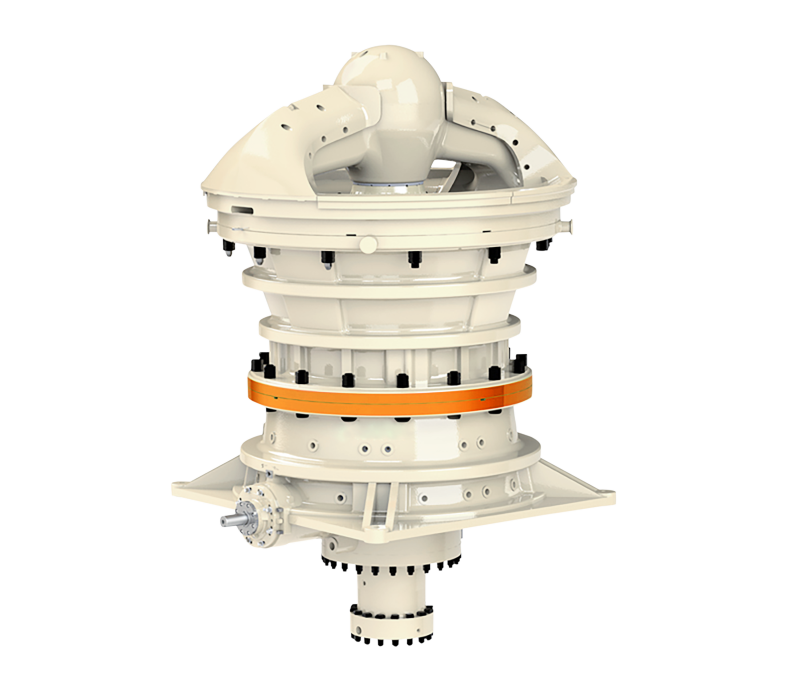

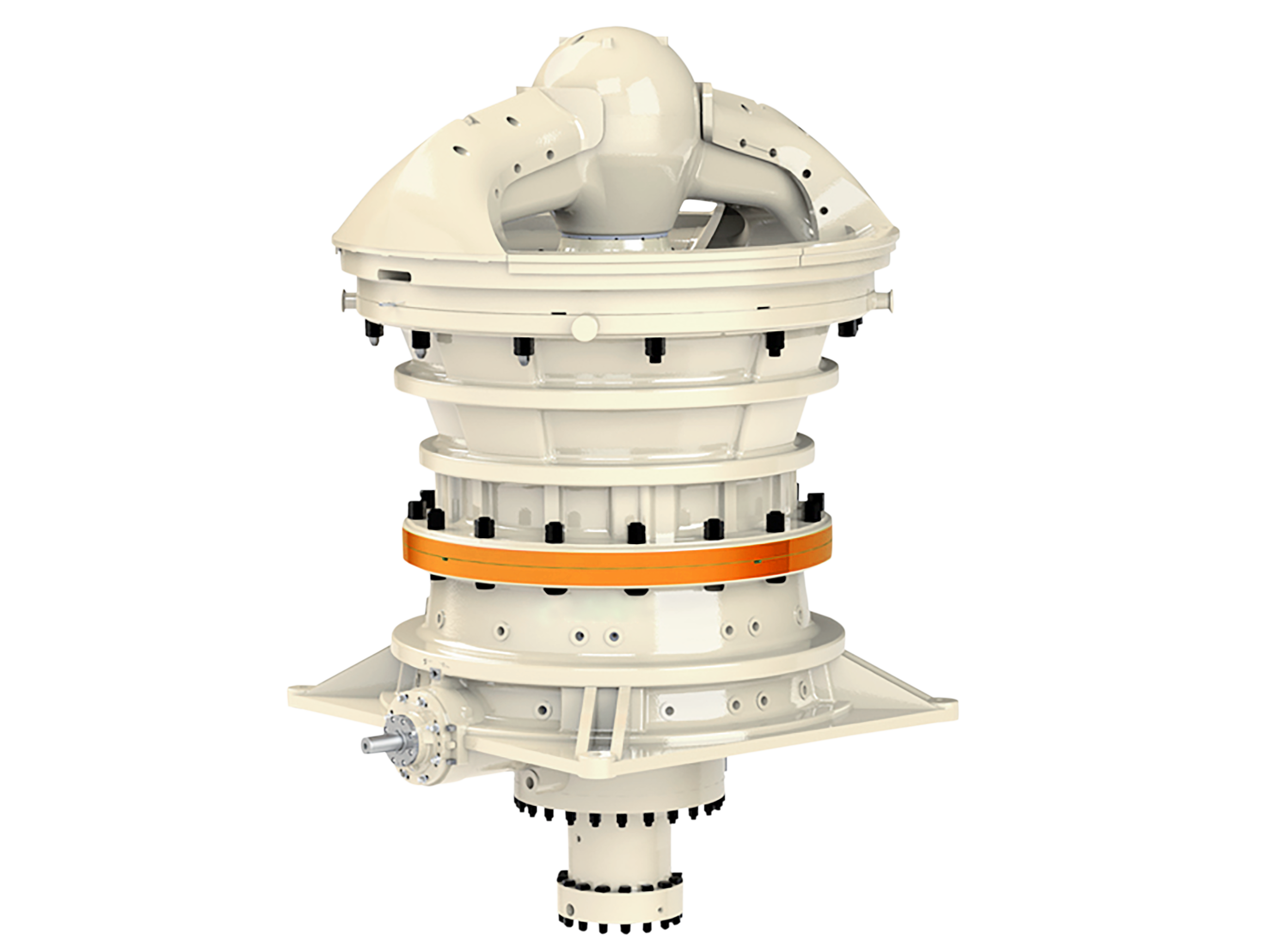

the GC5475 Gyratory Crusher

Description

Hebei Zhongwei GC Series Gyratory Crusher

High Capacity

High Crushing Efficiency

Large Crushing Ratio

Low Energy Consumption

Product Introduction:

The GC Series Gyratory Crusher is one of the most advanced primary crushers currently available internationally. It is suitable for the primary crushing of various rocks and ores. Compared to other primary crushing equipment, it features high capacity, high crushing efficiency, a large crushing ratio, uniform product size, low energy consumption, and even wear within the crushing chamber. It is an ideal primary crushing equipment for ultra-large mining and aggregate crushing systems.

The GC Series Gyratory Crusher is designed for ultra-heavy-duty conditions, pursuing high reliability under continuous, extremely heavy loads. It incorporates a low-carbon alloy cast steel frame, an alloy forged main shaft, spiral bevel gear design, hydraulic adjustment of the discharge opening, hydraulic cavity clearing, oil lubrication, and a positive pressure dust sealing system, enabling automated control. It offers convenient and quick maintenance, with low operating costs.

Product Features:

★ The crushing cavity accommodates large feed size, with an extra-deep cavity and a large crushing ratio.

★ Wear parts are standard high manganese steel; upper liners and lower frame hood can be optionally made of chromium alloy.

★ The dust seal is equipped with a high-pressure blower to prevent dust from entering the eccentric and drive assembly, increasing crusher bearing life.

★ Balanced design minimizes impact forces during operation, reducing the force transmitted to the supporting structure.

★ Replacement of the crossbeam bushing and oil seal does not require crossbeam removal, saving labor, time, and production losses from downtime.

★ Heavy-duty alloy steel main shaft, equipped with a threaded head bushing to reduce stress on the shaft.

★ A flame cutting ring installed under the head nut allows for quicker replacement of the mantle.

★ High-strength frame design adapts to various harsh working environments, ensuring smooth operation and extended service life.

★ The main shaft and head are one-piece forged, eliminating the possibility of loosening between the main shaft and head during crushing.

★ External adjustment for pinion backlash.

★ Step bearing wear indicator releases harmless silver powder into the oil when the bearing thickness is worn.

★ Convenient main shaft position sensor adjustment provides compensation control for product size as wear parts wear.

★ Modular design of the lubrication and hydraulic system operates independently. PLC-based control system interlocked with the main motor enables monitoring and recording of oil temperature, flow, pressure, power, abnormal voltage/current, etc., and protects the crusher.

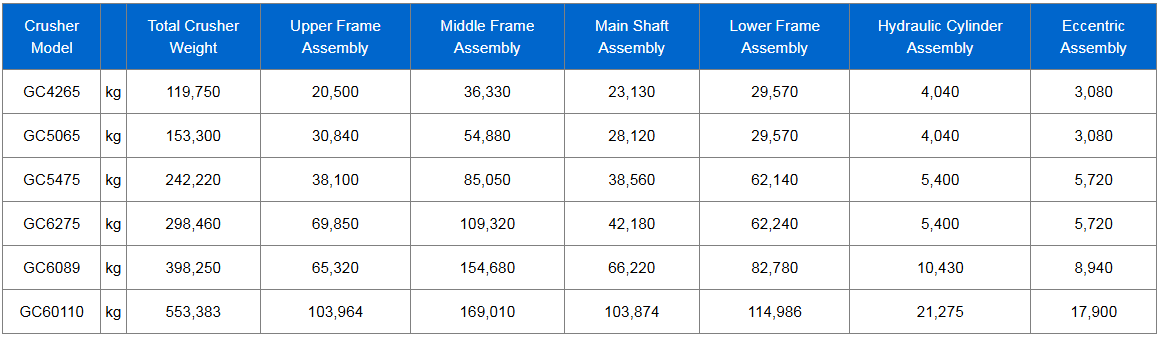

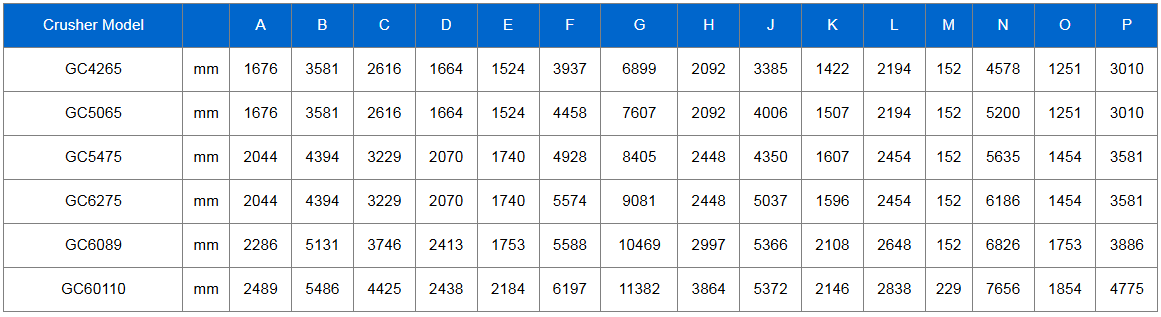

Technical Parameters:

The above capacities are based on assumed feed conditions where the maximum feed size is less than 0.8 times the feed opening; 80% of the feed is less than 0.6 times the feed opening; and 50% of the feed is less than 0.1 times the feed opening. These capacities apply to feed material with a bulk density of 1.6 tons per cubic meter.

All capacities are calculated based on the maximum throughput of each unit. All capacities are application-specific. Material characteristics, feed size and distribution, work index, moisture percentage, and feeding method are all factors when considering crusher capacity.

Company Profile:

Hebei Zhongwei Mining Machinery Manufacturing was founded in 1990. After 36 years of development, it has grown into a modern mining machinery manufacturing enterprise integrating scientific research, production, design and EPC project general contracting. It is a director unit of the China Sand and Gravel Association, a member unit of the China Heavy Machinery Association, and a vice president unit of the Hebei Sand and Gravel Association. It is also a qualified supplier for China Power Construction Corporation, China Railway Construction Corporation, China Railway Group, China Energy Construction Corporation, China Nonferrous Metal Mining Group, and China Communications Construction Company.

Hebei Zhongwei is located in Wangdu County, Hebei Province, in the center of the Beijing-Tianjin-Shijiazhuang triangle.Hebei Zhongwei has three mechanical factories and two steel foundries under its umbrella, covering a total area of 101,300 square meters and a construction area of 86,300 square meters. It is equipped with over 90 sets of specialized processing equipment and has more than 160 professional technicians and production workers. Its annual production capacity can reach 700 sets of mining machinery and equipment.

Hebei Zhongwei fully implements the "three systems" certification standards including ISO9001-2015 Quality Management System, ISO14001-2015 Environmental Management System, and ISO45001-2018 Occupational Health and Safety Management System. By introducing advanced foreign technologies and conducting independent research and development, it has produced 18 series of mining machinery and equipment, such as the C series European-style jaw crusher, GP series single-cylinder hydraulic cone crusher, HP series multi-cylinder hydraulic cone crusher, PCZ series hammer crusher, B series vertical shaft impact crusher, N series impact crusher, 2PG series hydraulic double-roller sand making machine, YKJ series thin oil lubrication maintenance-free circular vibrating screen, and ZSW series vibrating feeder. The high manganese steel wear-resistant parts independently cast and produced by Hebei Zhongwei feature advanced technology, low wear cost, and long service life. With excellent quality and comprehensive after-sales service, its products are sold all over the country and exported to the Middle East, Central Asia, Southeast Asia, Africa, South America, Mongolia, Russia and other countries and regions, receiving unanimous praise from customers.

${currentPro.title}