EN

Language

All categories

Product ID: 68580277

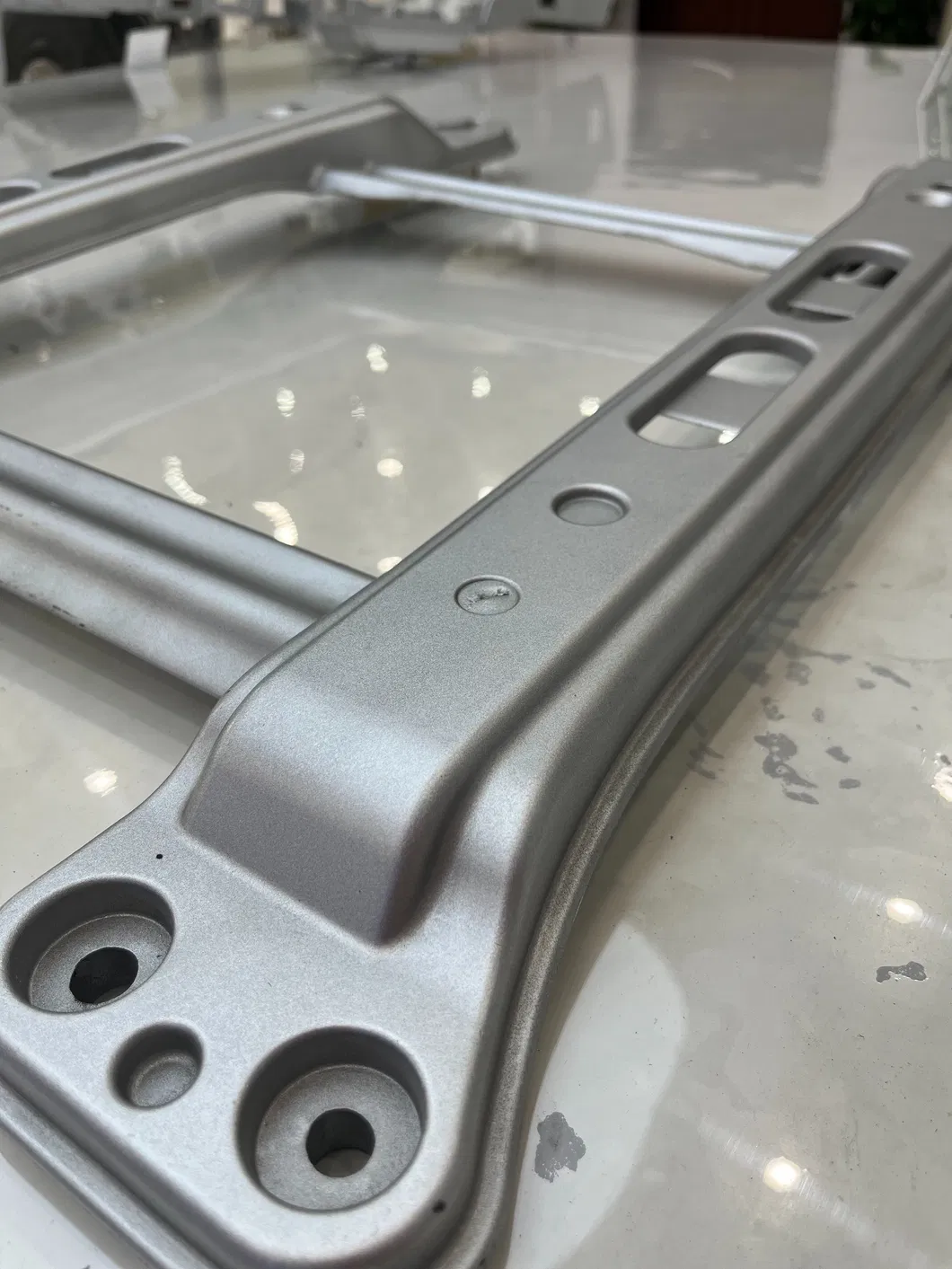

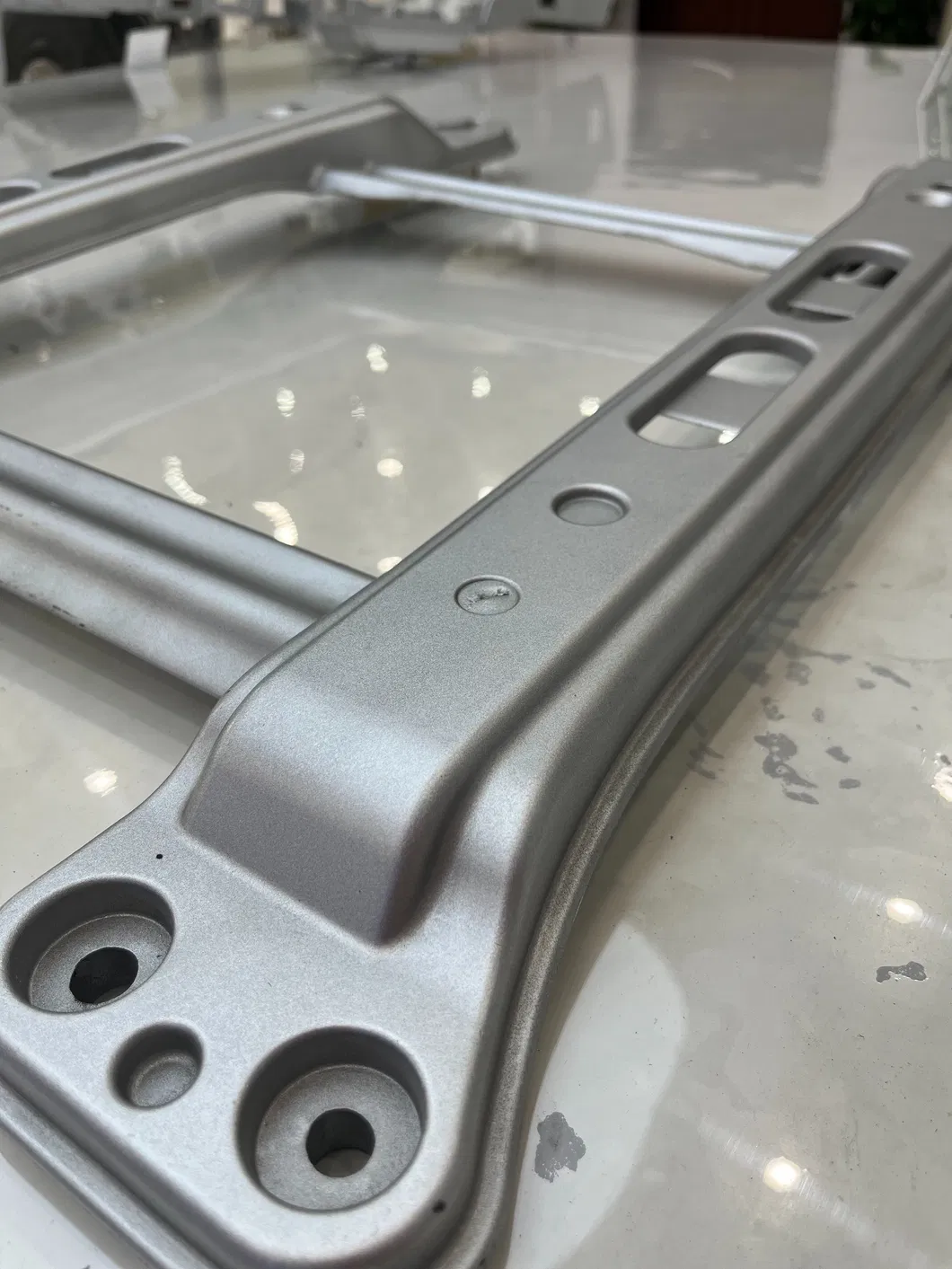

Precision Injection Mould for Enhanced Automotive Component Performance

Contact Now

Description

Basic Info.

Model NO.

BR-MOULD

Application

Car, Household Appliances, Home Use, Electronic, Hardware, Commodity

Material

Magnesium Alloy

Demoulding

Pull Core

Surface Treatment

Heat Treatment

Using Hardness

>HRC45

Average Wall Thickness

>3mm

Mould Life

>1,000,000 shots

Certification

ISO

Customized

Customized

Condition

New

Design Soft

Magma Ug

Technical Process1

Megacasting

Technical Process2

Gigacasting

Service

OEM & OEM Custmoziable

Advantage

Light-Weighted

Surface Treatment/Finish

Anodize, Chromate, Electrolytic Plating, Nickel P

Tolerance

as Customer Requirement

Material Standard

ISO, DIN, ASTM, Uns, AISI, JIS, BS, NF

Price Terms

EXW/Fob/CFR/CIF Shanghai or Any Other Airport or

Business Type

Manufacturer, Exportor

Main Product

Front Passenger Seat

Clamping Force

16,500kN

Type

Magnesium Alloy Auto Parts

Mold Weight

12.3t

Products Weight

12.2kg

Transport Package

Standard Exporting Wooden Case

Specification

4.8KG

Trademark

BR

Origin

Chongqing, China

HS Code

8480411000

Production Capacity

50PCS/Year

Packaging & Delivery

Package Size

100.00cm * 100.00cm * 100.00cm

Package Gross Weight

1000.000kg

Product Description

1. 2 Have two manufacturing bases,totally covers an area of more than 26000 square meters

2. 4 Only need 4 steps only:Upload and providing your design; Receiving design and analysis;Starting manufacturing;Receiving your parts

3. 15 With 15 years experiences on focusing on die casting mold innovation and manufacturing,established in 2009

4. 38 Have 38 patents whichcovers 5 invention patents and 33 utility model patents

5. 30% The proportion of key professional technician to total staff number

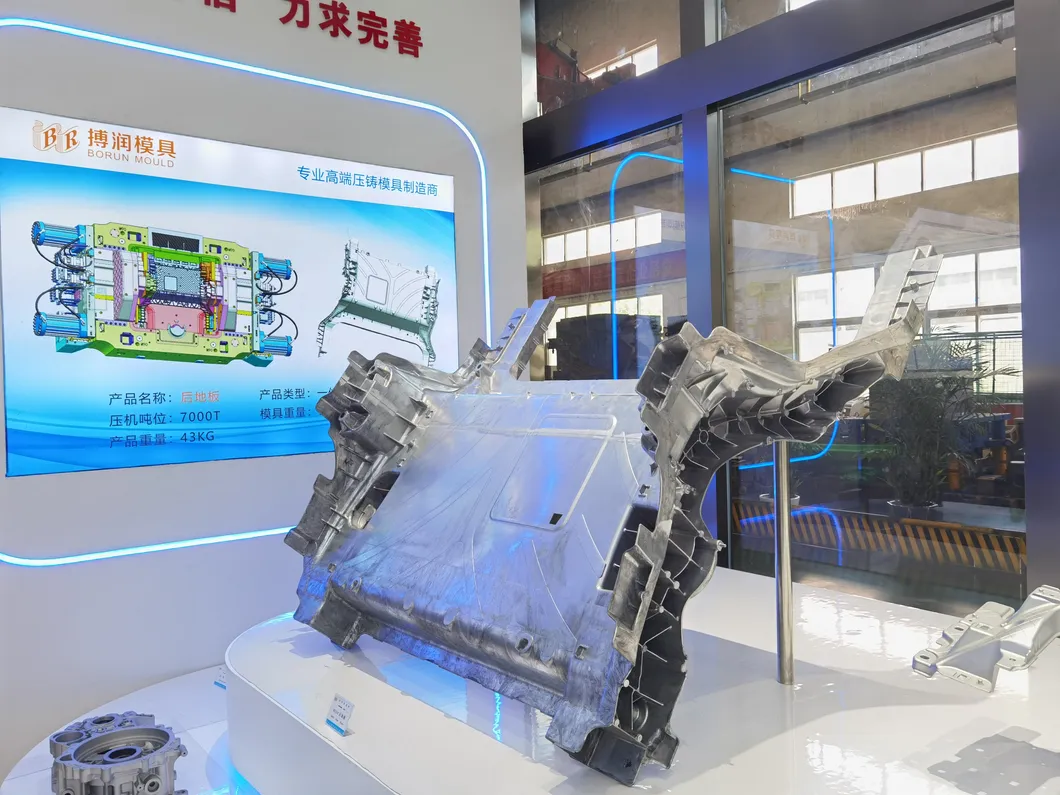

6. 400 Production capacity of 400sets covers from 50tons to 7000tons mold manufacturing capability

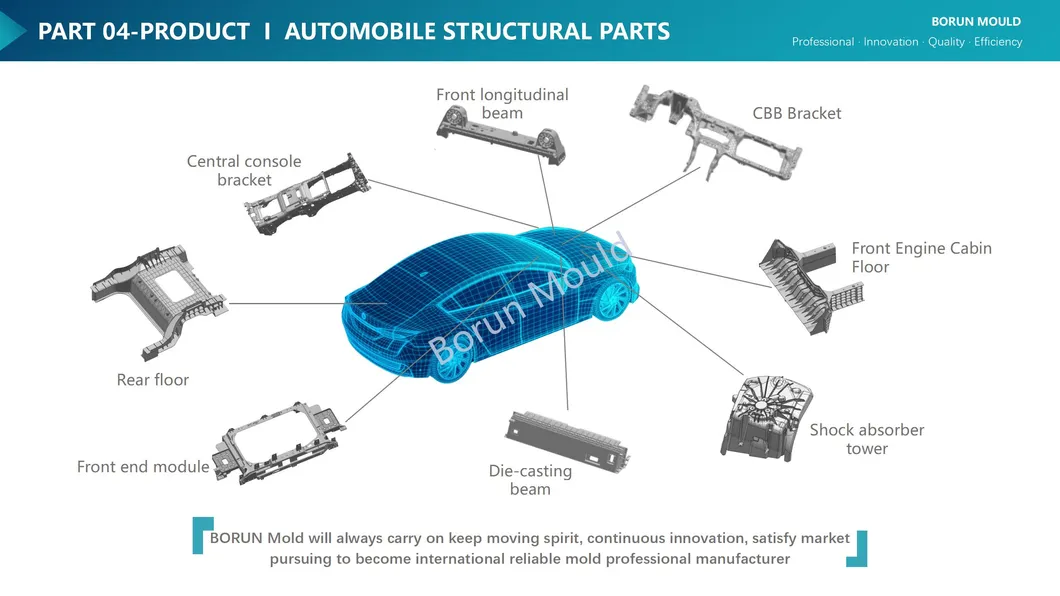

7. 7000 Our maximum diemold is 7000tons mold so far,we will develop new innovative larger gigacasting mould

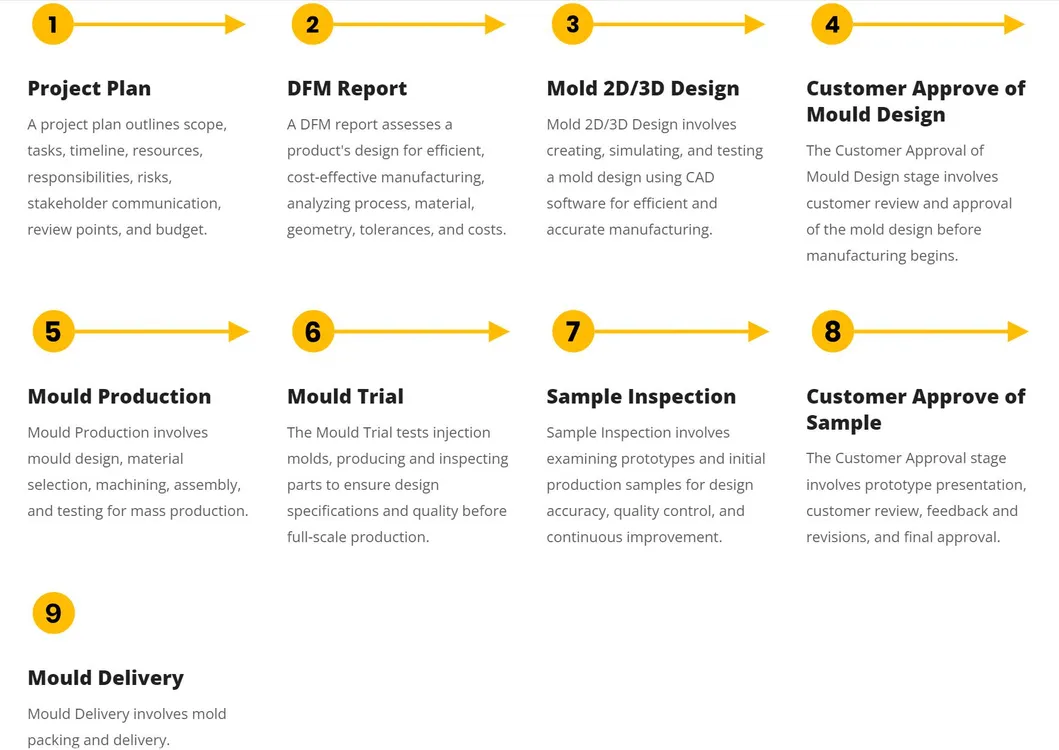

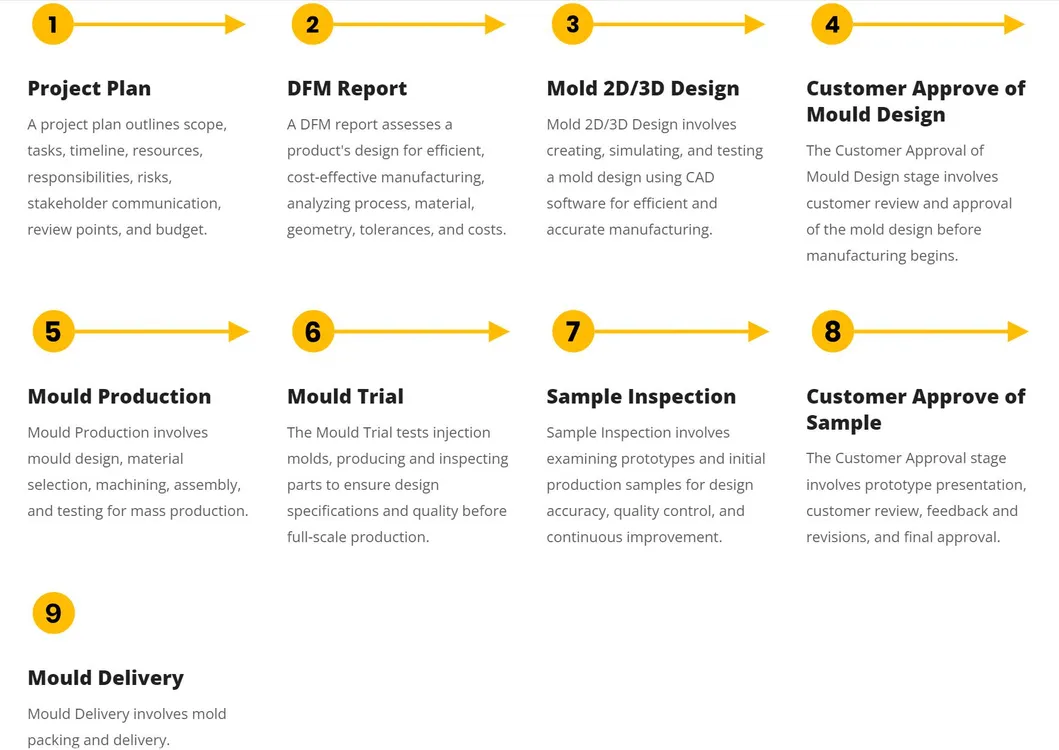

Manufacturing Flow Chart

Manufacturing Flow Chart

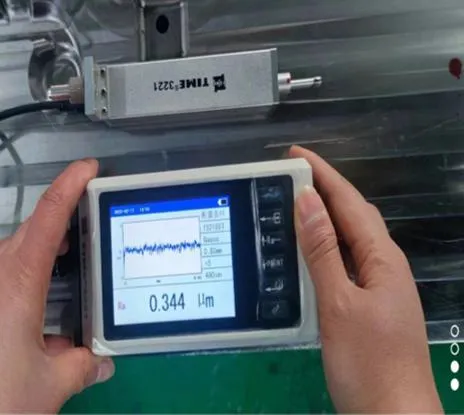

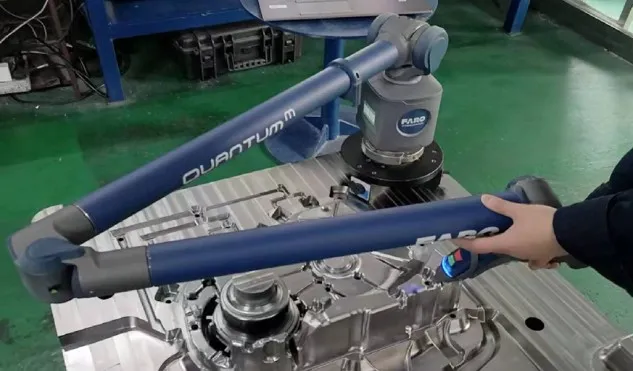

Factory Workshop

Factory Workshop

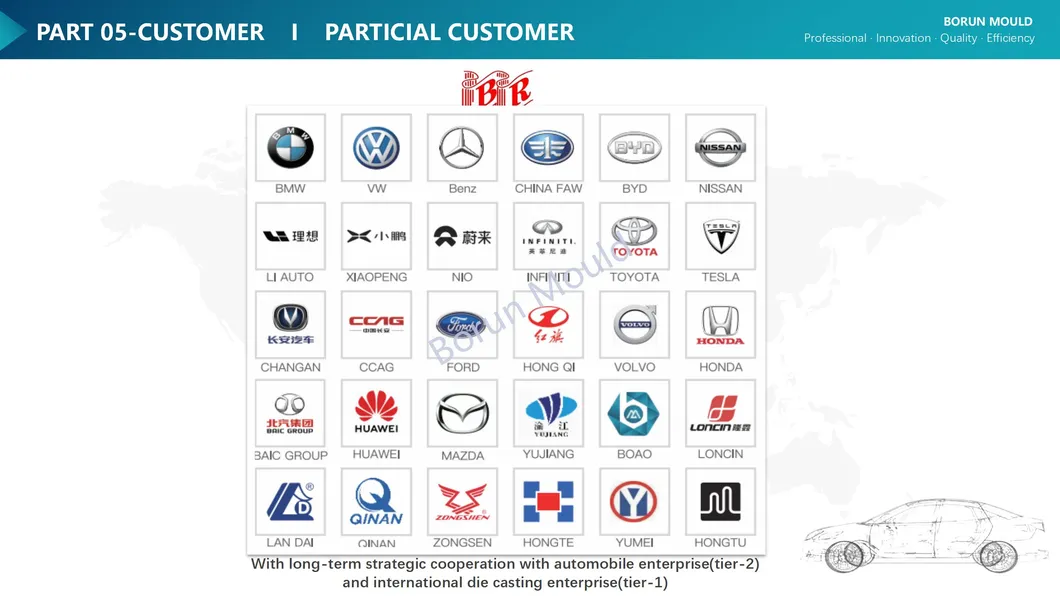

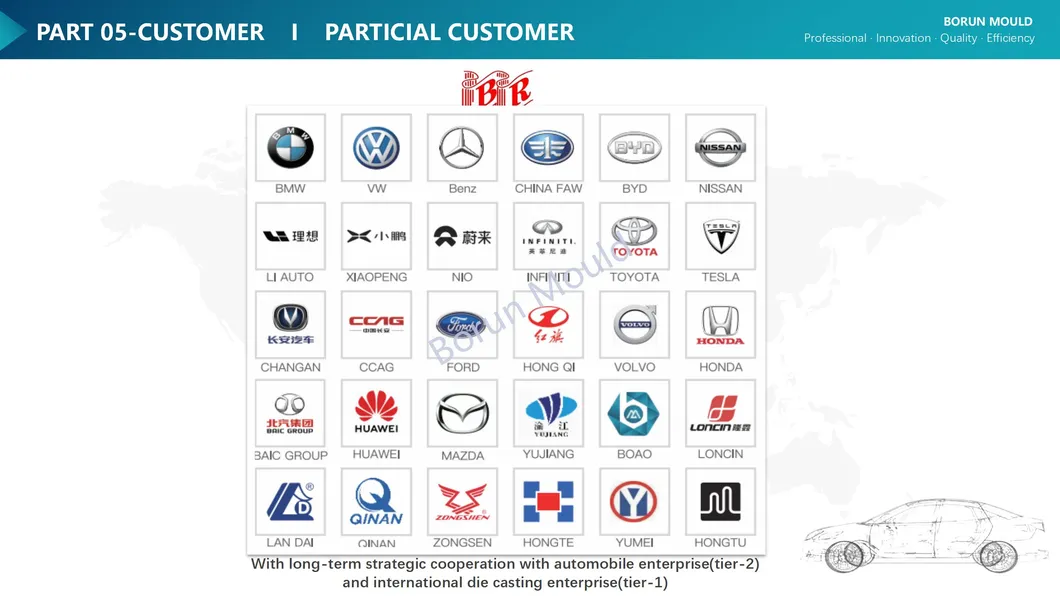

Our Esteemed Customers

Customers Visiting

2. 4 Only need 4 steps only:Upload and providing your design; Receiving design and analysis;Starting manufacturing;Receiving your parts

3. 15 With 15 years experiences on focusing on die casting mold innovation and manufacturing,established in 2009

4. 38 Have 38 patents whichcovers 5 invention patents and 33 utility model patents

5. 30% The proportion of key professional technician to total staff number

6. 400 Production capacity of 400sets covers from 50tons to 7000tons mold manufacturing capability

7. 7000 Our maximum diemold is 7000tons mold so far,we will develop new innovative larger gigacasting mould

Focus on large megacasting, sophisticate, precise & long lifetime die casting mould innovation and manufacturing

| Product Name | XXX Front Passenger Seat |

| Clamping Force | 16,500 KN |

| Product Type | Magnesium Alloy Auto Part |

| Mould Weight | 12.3 Tons |

| Products Weight | 2.2Kg |

| Demoulding | Automatic |

| Material | Magnesium Alloy |

| Tranport Package | Fumigation Wooden Case |

| Trade Mark | BR/OEM Acceptable |

| Certificate | ISO9001, SGS, TUV |

| Mold Life | 100,000 shots |

| HS Code | 8480411000 |

| Size | Customized |

| MOQ | 1 PC |

| Origin Place | Chongqing, China |

| Hardness | >HRC45 |

Established in 2009, Chongqing Borun Mould Manufacturing Co., Ltd. is a professional enterprise specialized in large-size, complicated, precise and long lifetime die casting mold innovation & manufacturing. As a unique professional HPDC casting mold manufacturer, we not only focus on precision and dimensional accuracy, but also focus on mold die OEE superior performance & win-win mutual benefit customer partnership relationship.

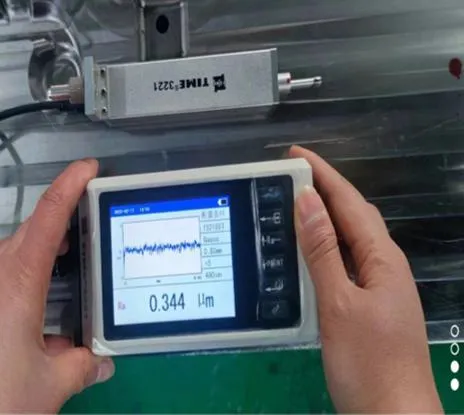

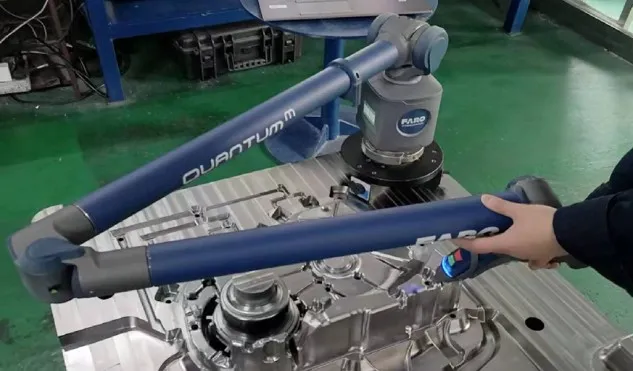

In order to ensure manufacturing high quality and reliable die mold, we utilized nice unique 5-axis CNC milling-machines which equipped with latest new generation control (stroke up to 3000 x 3000 x 12000mm). We can produce the die mold range from 200T to 8000Tons full wider range die casting mold series, and also have more than ten sets of large-scale mold die spotting equipment, high level Gantry machining centers and advanced precise CNC machines, large CNC-EDM machining center equipment, high-precision duplicating milling machines, precise electric pulse, EDM/WEDM and engraving machine, CMM Three coordinate measuring instrument and advanced ERP management system. CAD/CAE/CAM technology and ERP production process management system, the mold design, computer analysis, CNC machining, inspection and other work are integrated. Under the guarantee of state-of-the-art of equipment, advanced management and excellent technology, the mold production cycle time is greatly shortened.

The mold design mainly uses UG8.0, Solidworks and Pro/E development and R&D platform software, and run some three-dimensional modeling and simulation flow analysis as well as overall structure design and innovation updating. The model flow analysis adopts genius MAGMA and flow 3D model analysis software.

We have been recognized and highly praised by esteemed direct or indirect customers as BWM, Mercedes-Benz, VW, Ford, Linamar, GM, FAW-VW, BorgWarner, TESLA, Benz, Audi, Volvo, Honda, TOYOTA, NISSAN, INFINITI, CHANGAN, Yujiang and Refine Yumei tier, Qinan, Zongshen tier1 or tier2 clients all over the world and establish a long-term cooperation with them on die casting mold innovation and manufacturing. Also we have launched development and manufacturing of new energy sources fields, lightweight automobile structural parts, magnesium-aluminum alloy die mould and communication 5G products die mould developments. NEV double electric control case, 75KW housing, 150KW rotary transformer end cover, 220KW motor housing and intermediate housing box, CCB bracket, seat frame PCF bracket and hinge slide rail bracket, steering wheel, 5G shield cover case etc….

In order to ensure manufacturing high quality and reliable die mold, we utilized nice unique 5-axis CNC milling-machines which equipped with latest new generation control (stroke up to 3000 x 3000 x 12000mm). We can produce the die mold range from 200T to 8000Tons full wider range die casting mold series, and also have more than ten sets of large-scale mold die spotting equipment, high level Gantry machining centers and advanced precise CNC machines, large CNC-EDM machining center equipment, high-precision duplicating milling machines, precise electric pulse, EDM/WEDM and engraving machine, CMM Three coordinate measuring instrument and advanced ERP management system. CAD/CAE/CAM technology and ERP production process management system, the mold design, computer analysis, CNC machining, inspection and other work are integrated. Under the guarantee of state-of-the-art of equipment, advanced management and excellent technology, the mold production cycle time is greatly shortened.

The mold design mainly uses UG8.0, Solidworks and Pro/E development and R&D platform software, and run some three-dimensional modeling and simulation flow analysis as well as overall structure design and innovation updating. The model flow analysis adopts genius MAGMA and flow 3D model analysis software.

We have been recognized and highly praised by esteemed direct or indirect customers as BWM, Mercedes-Benz, VW, Ford, Linamar, GM, FAW-VW, BorgWarner, TESLA, Benz, Audi, Volvo, Honda, TOYOTA, NISSAN, INFINITI, CHANGAN, Yujiang and Refine Yumei tier, Qinan, Zongshen tier1 or tier2 clients all over the world and establish a long-term cooperation with them on die casting mold innovation and manufacturing. Also we have launched development and manufacturing of new energy sources fields, lightweight automobile structural parts, magnesium-aluminum alloy die mould and communication 5G products die mould developments. NEV double electric control case, 75KW housing, 150KW rotary transformer end cover, 220KW motor housing and intermediate housing box, CCB bracket, seat frame PCF bracket and hinge slide rail bracket, steering wheel, 5G shield cover case etc….

Our Esteemed Customers

Customers Visiting

Our Team

Contact Now

Please Send Message

${currentPro.title}