EN

Language

All categories

Product ID: 68580280

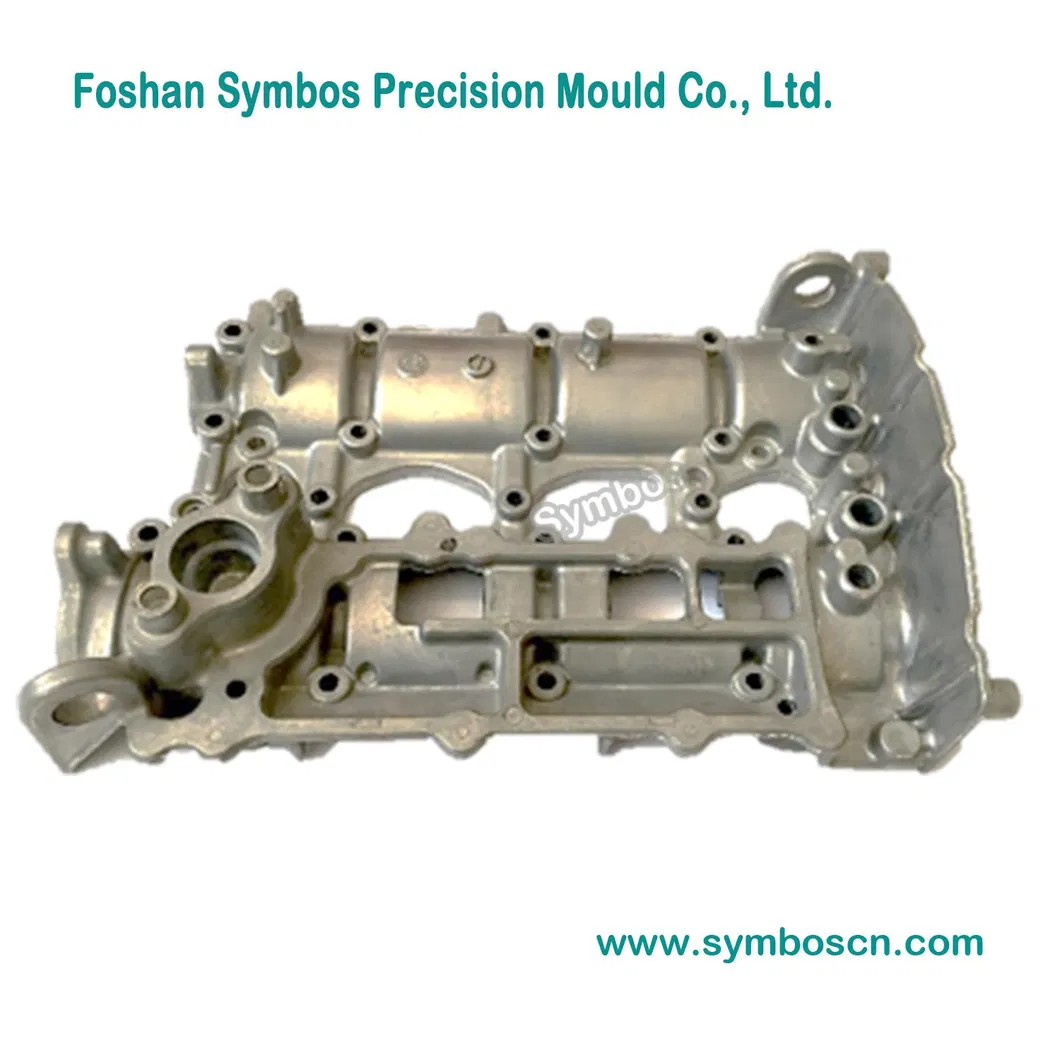

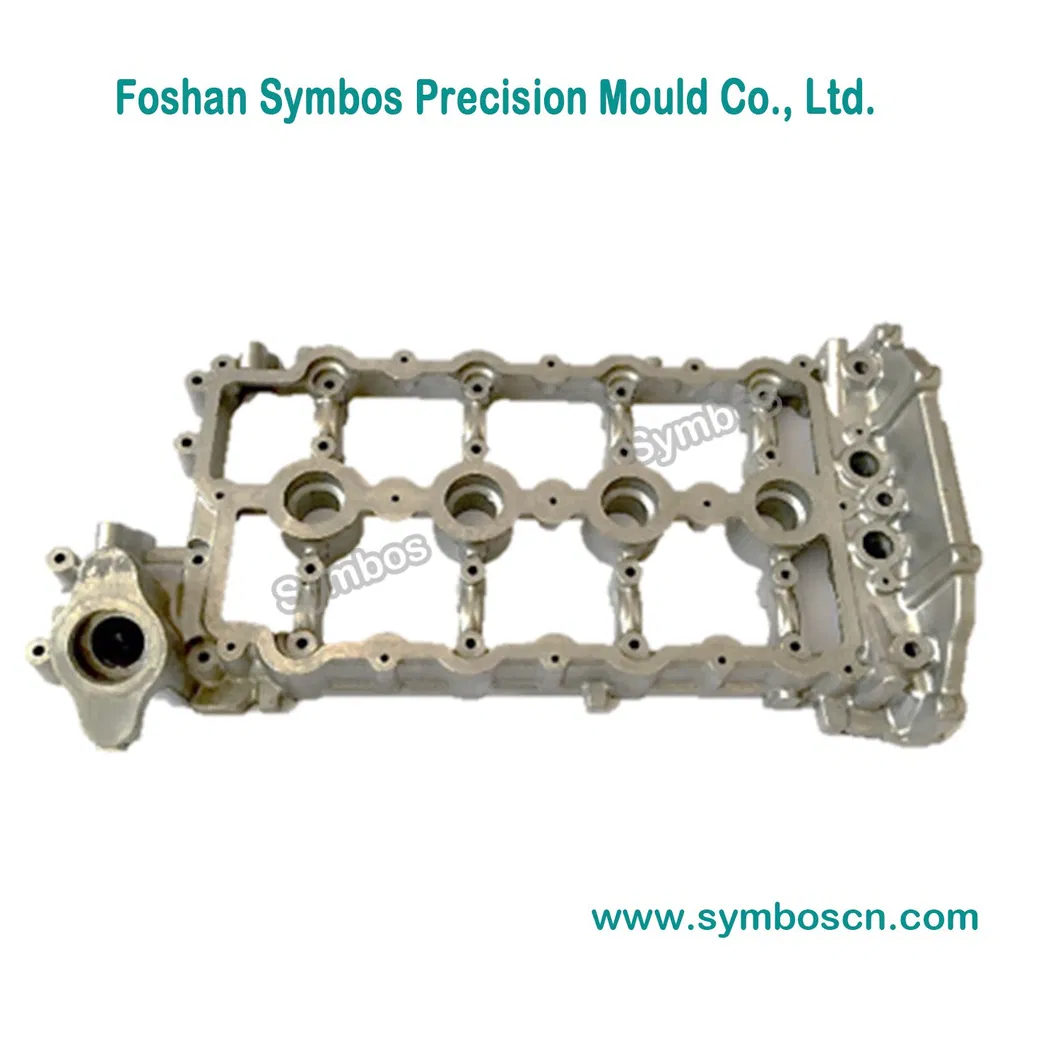

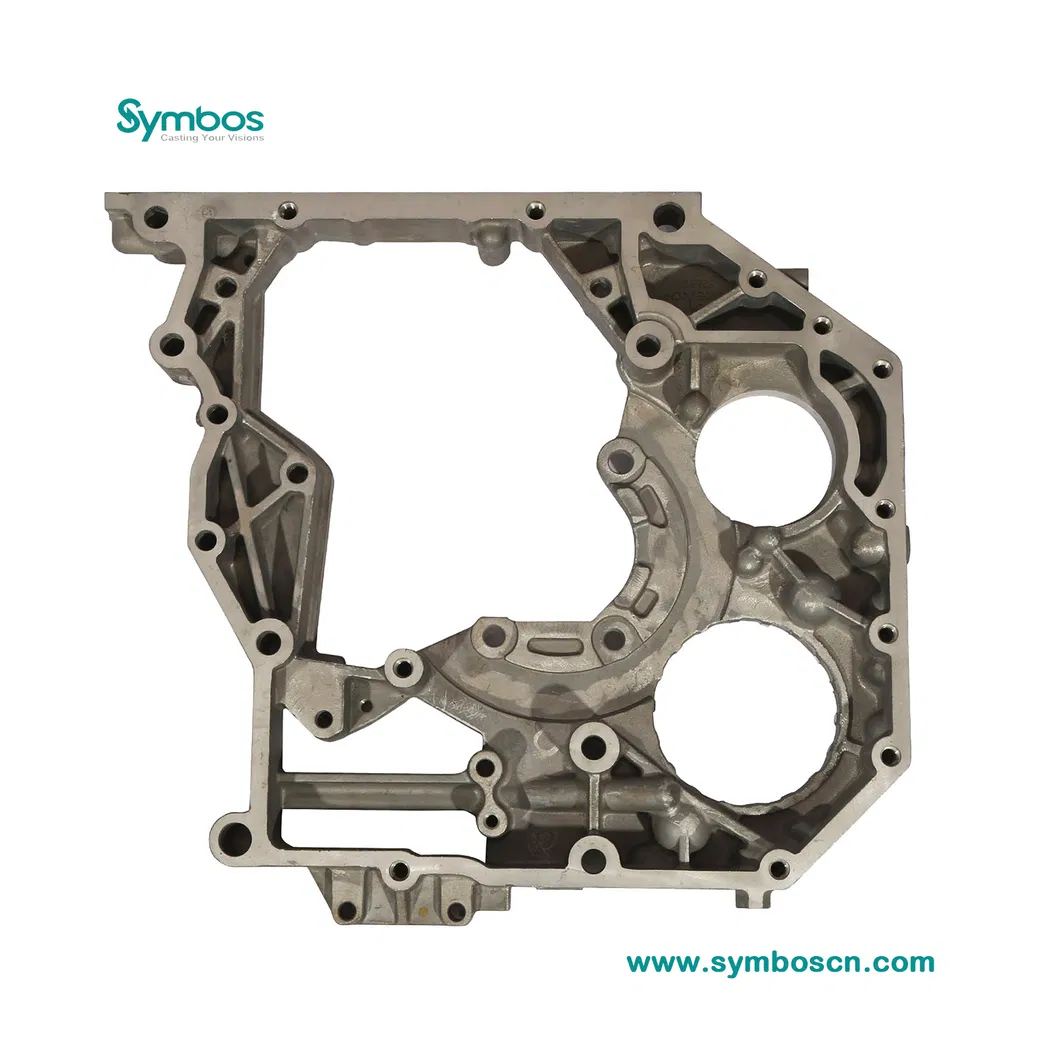

Aluminum Die Casting Mold for Automotive Components

Contact Now

Description

Overview

Basic Info

- Model NO. SYM-A91

- Application Car, Household Appliances, Home Use, Electronic, Hardware, Commodity

- Material Aluminium

- Demoulding Automatic

- Surface Treatment Heat Treatment

- Using Hardness >HRC45

- Average Wall Thickness >3mm

- Mould Life >1,000,000 shots

- Certification REACH, FCC, RoHs, CE

- Customized Customized

- Condition New

- Transport Package Packing for Export

- Trademark Symbos

- Origin China

- HS Code 8480411000

Packaging & Delivery

- Package Size 103.00cm * 150.00cm * 69.00cm

- Package Gross Weight 1200.000kg

Product Description

Product name: High Pressure Die Casting Mold

Mould Material: H13, DIEVAR, SKD61, 8407, 8418, 1.2343, 1.2344, 1.2367, 3Cr2W8V, 4Cr5MoSiV, W400, DAC55, DH-31, etc.

Casting Alloy: Aluminum, Magnesium

Cavity Qty: Single Cavity, Multiple Cavity or Unit Cavity

Tonnage: 200T-4400T

Treatment: Heat Treatment, Nitriding, Polishing etc.

Mold Life: 50,000 to 300,000 depend on products

Applications:

- 1. Automobile and motorcycle parts;

- 2. Telecom Parts;

- 3. Electrical appliance parts;

- 4. Lights & lamps parts;

- 5. Industrial hardware and Machine Sparepart;

- 6. Household Appliance parts;

- 7. Medical Instrument parts;

Lead Time: 35-60 days

Special request: According to customer's request

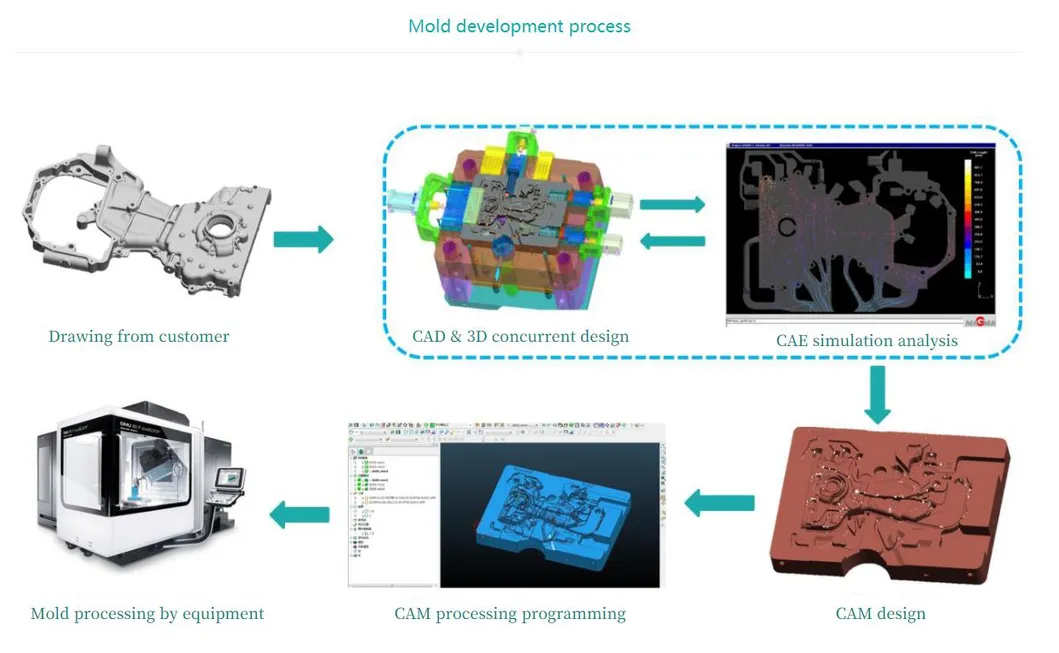

Our Advantages

- Around 20 years mold making experience, certificated with IS09001 & IATF 16949 and with skilled and professional workers. We are the expert at Strong engineering, exquisite workmanship, products of various materials high precision request and complex shapes;

- More than 30 countries export experience ensure our technical team are able to offer tailor-made service with International standard towards to our customers;

- We are big company group investing a lot on hardware and software facilities. We have advanced and high precision equipment and machines as well as latest mold design software and mold flow analysis software;

- Work with many world class Japanese brands, sound & rigorous Japanese management and quality control system. Very high quality in the industry;

- Direct export to be sure cost-effective and competitive. For some mature molds, we are 20-30% cheaper than others;

- Three factories guarantee our plenty production capacity and our short lead time and quick response capability;

- Familiar with material industry, to use high quality materials to be sure long life time and excellent hot runner system and cooling system to increase production efficiency;

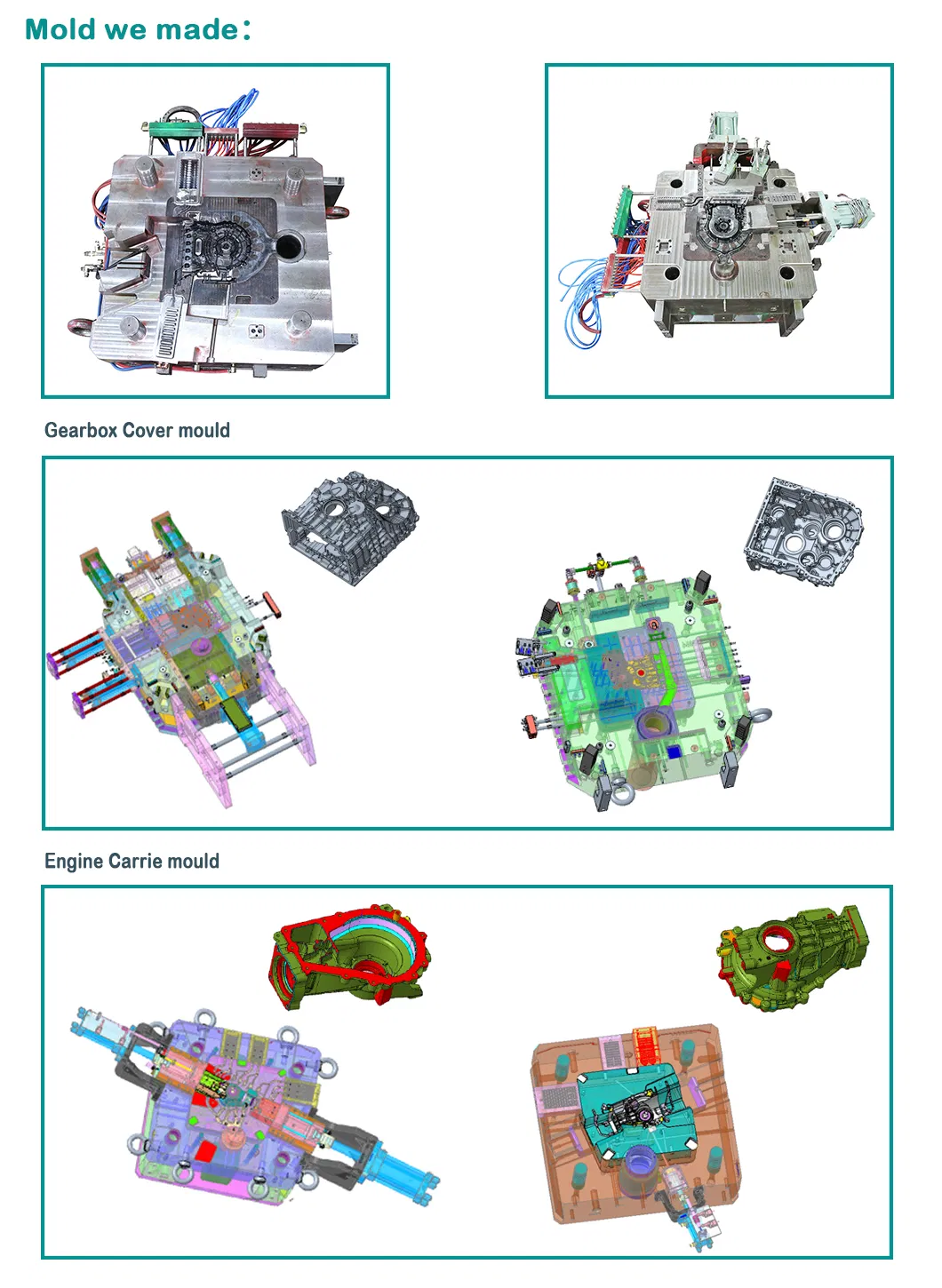

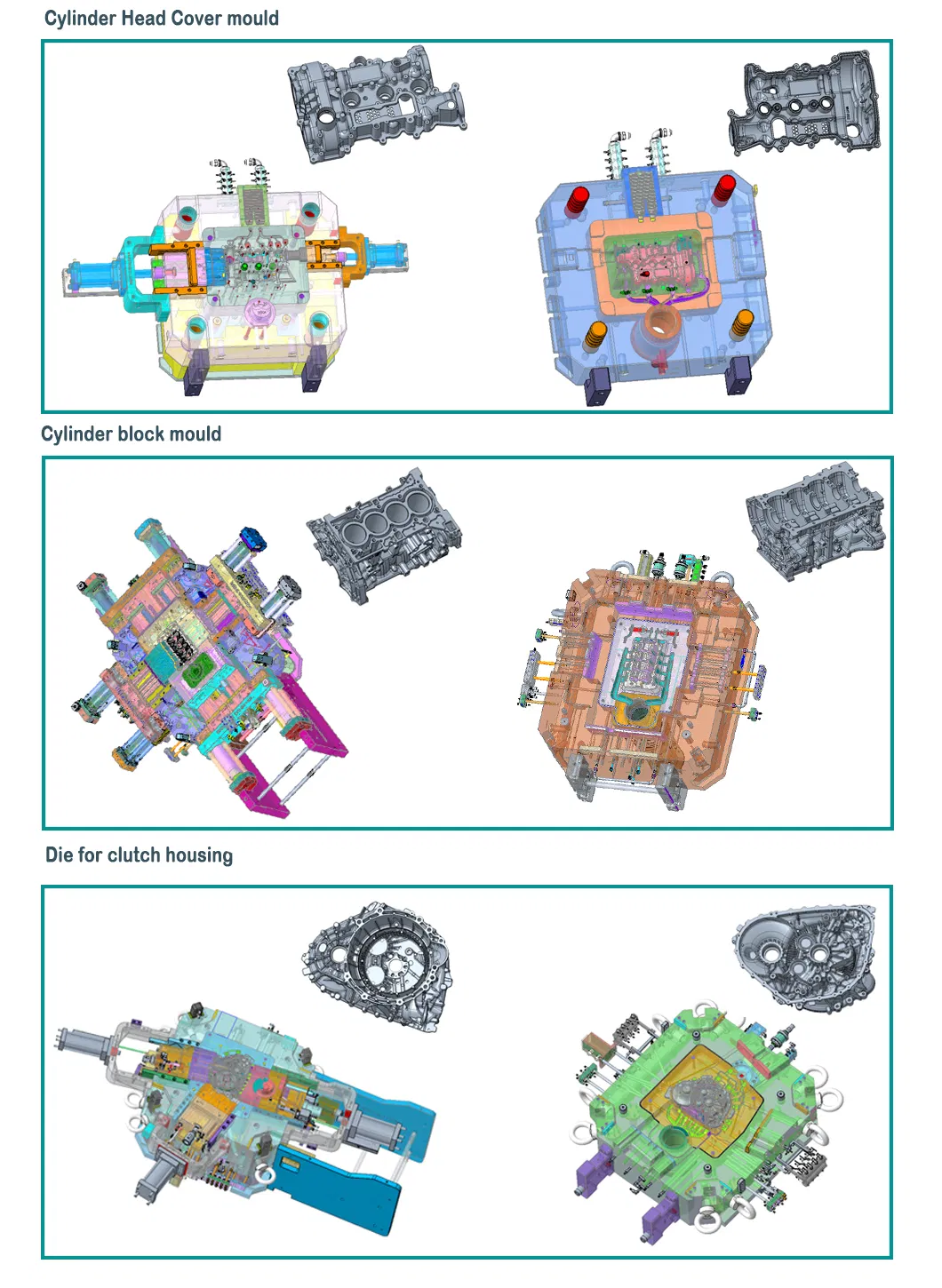

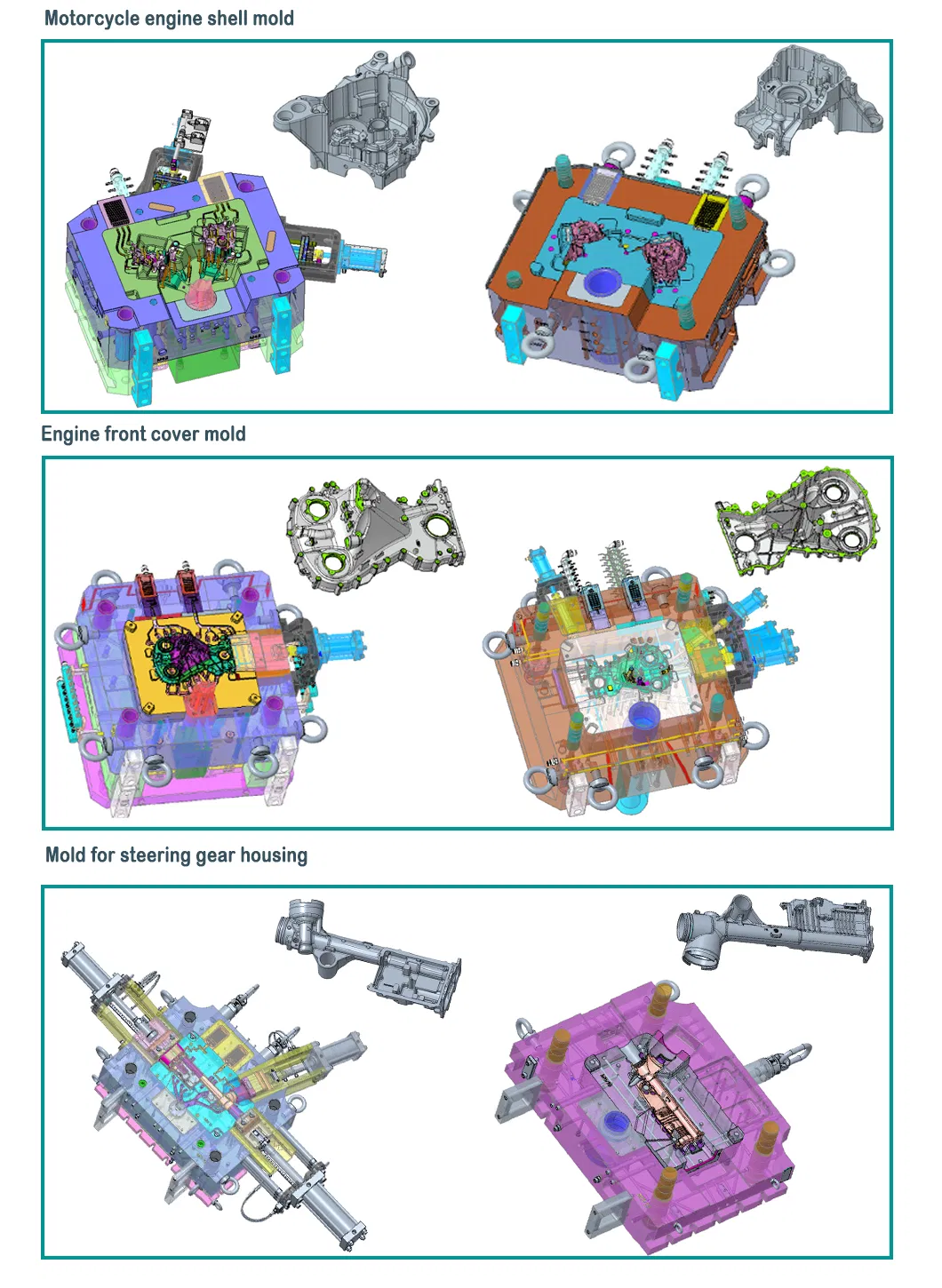

Mold & Molding Parts We Made

Patents Awards Certificates

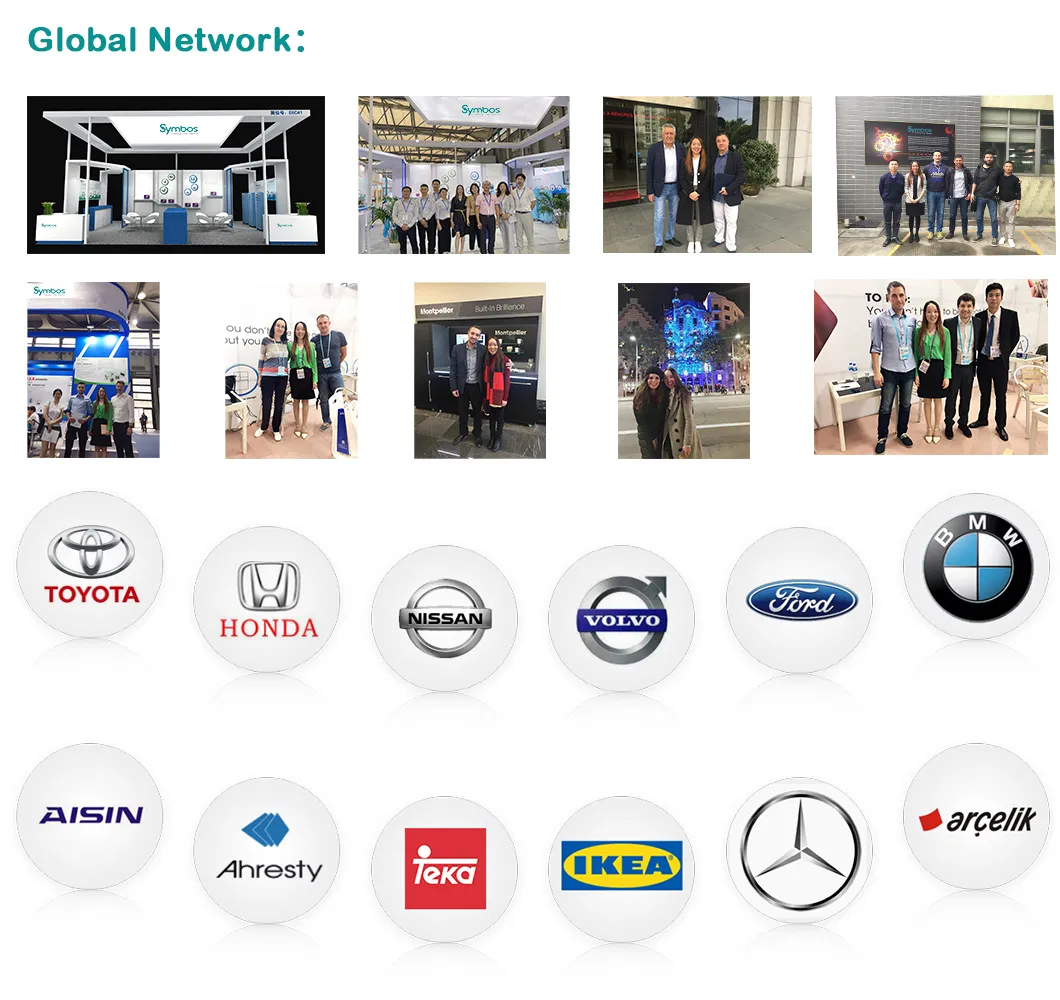

Global customers & Exhibition

Contact Now

Please Send Message

${currentPro.title}