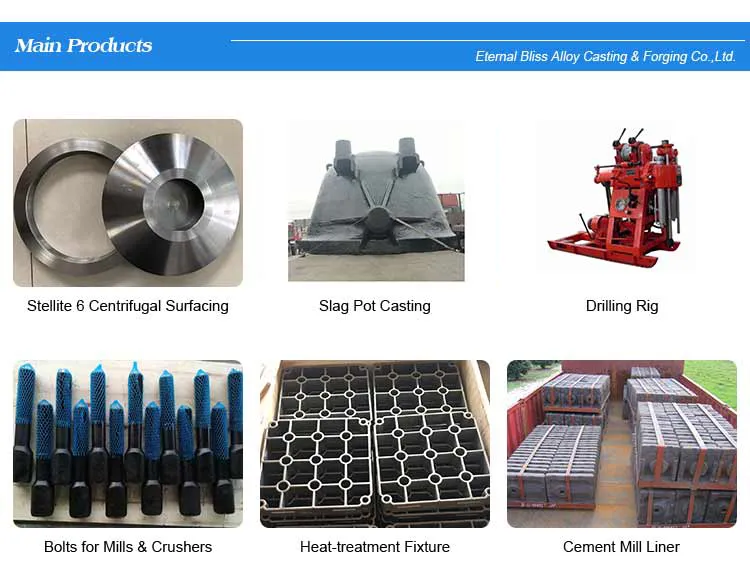

Wear-Resistant Lining for Power Plant Cement Mills

Description

Basic Info

- Model NO. EB0928

- Sand Core Type Resin Sand Core

- Application Furniture Parts

- Machining EDM Machining

- Material High Cr Cast Iron

- Surface Treatment Spray-Paint

- Surface Roughness Ra0.05

- Standard As2027 Cr35

- Certification ISO 9001:2008

- Size According to Customer's Drawings

- Service OEM ODM

- Process Sand Cast Process

- Features 7 Times More Life Than High Mangnese Steel

- Transport Package Pallets

- Trademark EB

- Origin China

- HS Code 8474900000

- Production Capacity 10000 Tons Per Year

Product Description

Product Description:

1. Material: High Cr cast iron;

2. Standard: AS2027 Cr35;

3. Wear plate thickness: 10mm, 12mm, 14mm, 16mm, 18mm, 15mm, 20mm, 15mm, 30mm, 32mm, 40mm, 50mm, 60mm, 80mm, 100mm, 200mm, 500mm, 1000mm;

4. Section thickness: 1 ″, 2 ″, 3 ″, 4 ″, 5 ″, 8 ″, 10 ″, 20 ″, 30 ″, 40 ″;

5. Shape: flat plate, curved plate, corrugated plate;

6. Bolt plate: single hole, double hole, three hole, four hole, oval hole.

Main Feature:

1. Scope of application: Clinker silo protection board of cement plant, lining of chute of port machinery, lining of steel hopper, high wear-resistant board of silo of port machinery, wear-resistant protection board of coal warehouse

2. We provide designs for wear plates and chute liners.

3. The width and length of the wear plate determine the arrangement and number of screw holes.

4. Material selection of wear-resistant and chute liner.

Chemical Composition:

| Reference Standard | Nominal Chemical Composition (W%) | Eqv. Standards |

|---|---|---|

| ISO 21988-2005 | C: 1.8-3.6, Si: ≤1.0, Mn: 0.5-1.5, Ni: ≤2.0, Cr: 11.0-14.0, Mo: ≤3.0, Cu: ≤1.2, P: ≤0.08, S: ≤0.08 | EN-GJN-HV600(XCr13), ASTM A532 12% Cr |

| ISO 21988/JN/ HBW555XCr16 | C: 1.8-3.6, Si: ≤1.0, Mn: 0.5-1.5, Ni: ≤2.0, Cr: 14.0-18.0, Mo: ≤3.0, Cu: ≤1.2, P: ≤0.08, S: ≤0.08 | EN-GJN-HV600(XCr14), ASTM A532 15% Cr-Mo, AS 2027 CrMo 15 3, G-X 300 CrMoNi 15 2 1 |

| ISO 21988/JN/ HBW555XCr21 | C: 1.8-3.6, Si: ≤1.0, Mn: 0.5-1.5, Ni: ≤2.0, Cr: 18.0-23.00, Mo: ≤3.0, Cu: ≤1.2, P: ≤0.08, S: ≤0.08 | EN-GJN-HV600(XCr18), ASTM A532 20% Cr-Mo, AS 2027 CrMo 20 1, G-X 260 CrMoNi 20 2 1 |

| ISO 21988/JN/ HBW555XCr27 | C: 1.8-3.6, Si: ≤1.0, Mn: 0.5-2.0, Ni: ≤2.0, Cr: 23.0-30.0, Mo: ≤3.0, Cu: ≤1.2, P: ≤0.08, S: ≤0.08 | EN-GJN-HV600(XCr23), ASTM A532 25% Cr-Mo, AS 2027 Cr27 LC & Cr27 HC, G-X 260 Cr27 |

| ISO 21988/JN/ HBW600XCr35 | C: 3.0-5.5, Si: ≤1.0, Mn: 1.0-3.0, Ni: ≤1.0, Cr: 30.0-40.0, Mo: ≤1.5, Cu: ≤1.2, P: ≤0.06, S: ≤0.06 | AS 2027 Cr35 |

| ISO 21988/JN/ HBW600XCr20Mo2Cu | C: 2.6-2.9, Si: ≤1.0, Mn: ≤1.0, Ni: ≤1.0, Cr: 18.0-21.0, Mo: 1.4-2.0, Cu: 0.8-1.2, P: ≤0.06, S: ≤0.06 | AS 2027 CrMoCu 20 2 1 |

Frequently Asked Questions

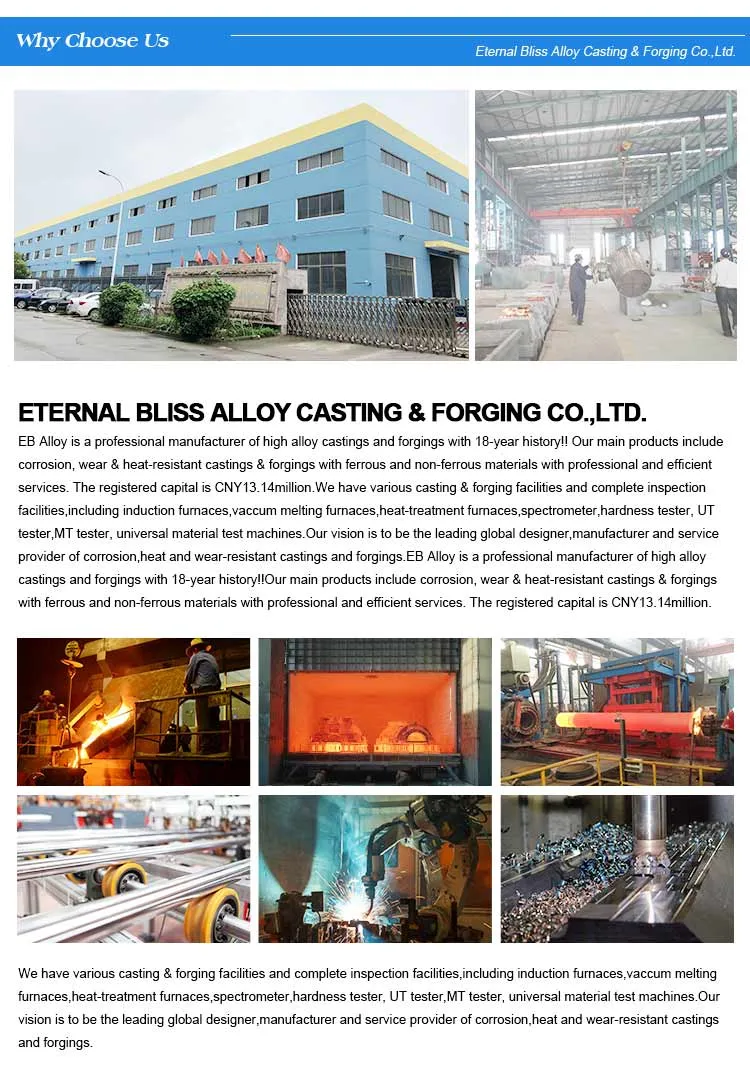

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5~10 days if the goods are in stock. Or it is 45 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment?

A: Payment <= 1000USD, 100% in advance. Payment >= 1000USD, 50% T/T in advance, balance before shipment. irrevocable LC at sight.

${currentPro.title}