High-Performance Abrasive Resistant 99% Alumina Ceramic Bricks for Mining Applications

Description

Overview

Basic Info.

- Model NO. Ball Mill Bricks

- Material Aluminum

- Type Wear Resistant Ceramic

- Square Tile 10X10X3~10mm, 17.5X17.5X3~15mm, 20X20X3~15mm, etc.

- Ceramic Plate 100X100X6~50mm, 150X100X6~50mm, etc.

- Hexagonal Tile S12.5xt3~20mm, S23.5xt6-25mm

- Dimple Tiles 20X20X4-10+1(with 5 Dimples), 20X30X5~15+1(with 18 dimples), 20X20X5-10mm( with 13 dimples)

- Ceramic Block 40X40X40mm, 45X45X50mm,32X32X22mm, 38X38X38mm,etc.

- Ceramic Cylinder/Rod 6X6mm,15X15mm,20X20mm, 31X31mm,40X40mm, 45X50mm, 50X50mm etc.

- Al2O3 99%

- Density 3.83G/Cm3

- Hv 20 1200

- Rock Hardness Hra 90

- Bending Strength MPa 330

- Compression Strength MPa 1800

- Fracture Toughness Kic Mpam 1/2 4.2

- Wear Volume 0.10 Cm3

- Transport Package Box

- Trademark firstar

- Origin China

- HS Code 6909120000

- Production Capacity 400t/Month

Product Description

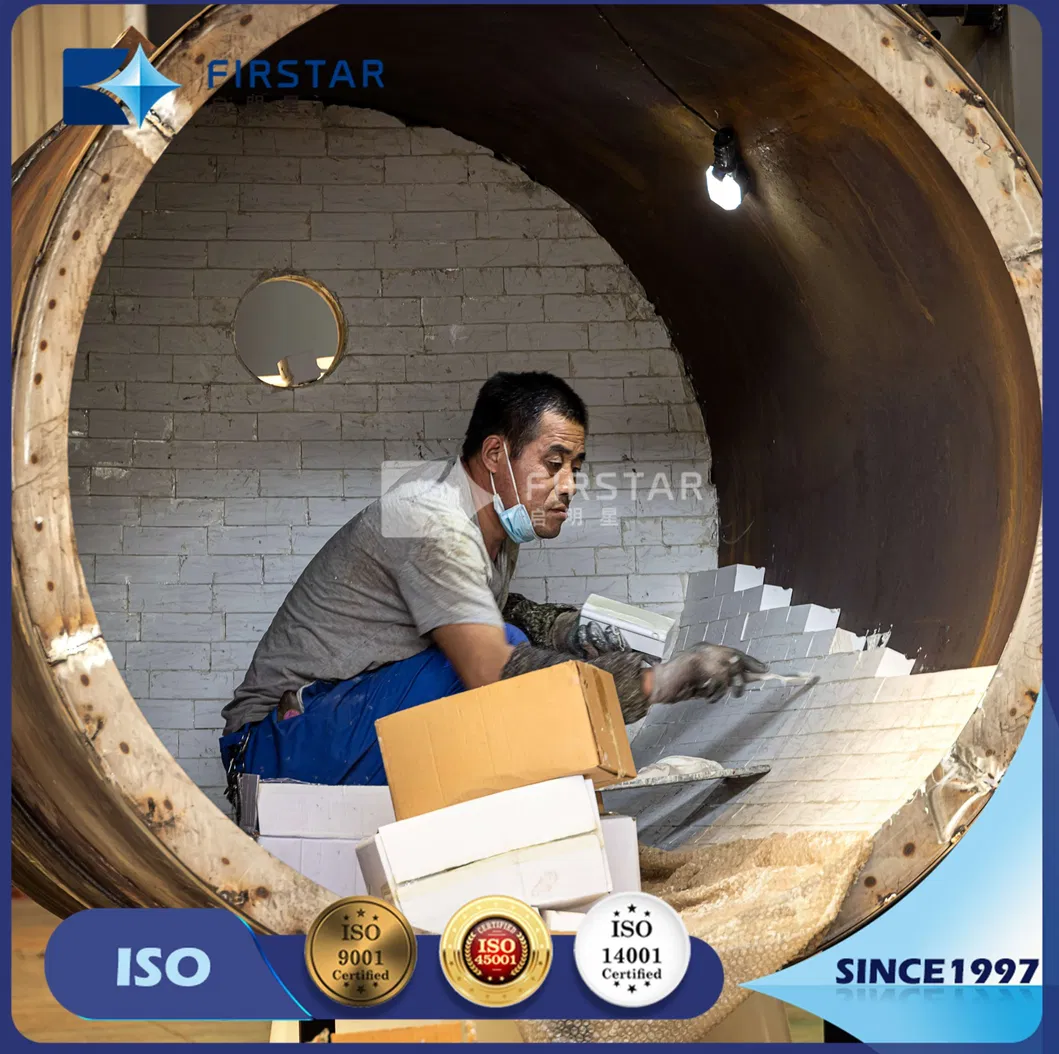

Abrasive Resistant 99% Alumina Ceramic Bricks Lining for Mining Industry

1. Detailed description:

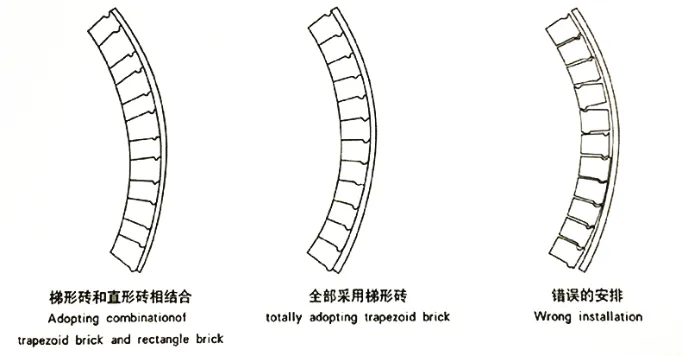

The Ceramic brick is a high-performance abrasion and impact resisting linings for high-impact, high-pressure applications in which ceramic tile may not have sufficient structural resistance, and high-performance rubber may not offer the required wear life. In extreme applications, the Cube liners can be installed in a matrix or abrasion resistant steel plate to provide structural support for the ceramic/rubber matrix and provide exceptional wear life where competing products cannot.

QMX's wear resistant ceramic tiles can be cut into any shape and are easy to install and maintain. They are suitable for both wet and dry processing applications. Advanced ceramics combine high strength and toughness with extreme hardness to deliver exceptional wear resistance.

1. Alumina wear resistant compositions include:

- Ceramic Mosaic Pieces

- Ceramic Pipe Tiles

- Ceramic Curved Tiles (with or without holes)

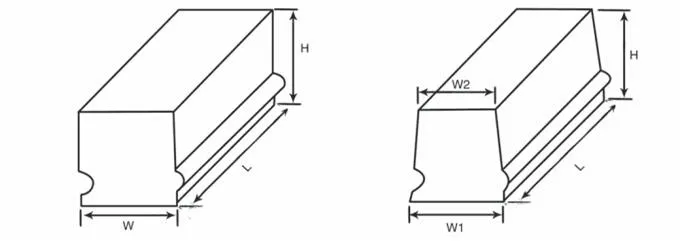

- Ceramic Tapered Tiles

- Ceramic Cylinders

- Steel Lined with Ceramic Tiles

- Irregular Ceramic Tiles

- Clipping Ceramic Tiles Interlocking Bricks

l Alumina 92: most common wear product with great wear resistance

l Alumina 95: increased wear performance

l Alumina T95: premium alumina for best wear resistance

l Zirconium toughened alumina (ZTA): increased strength and impact resistance

2. Product features:

- > High hardness

- > Superior abrasion and impact resistance

- > Corrosion and chemical resistance

- > Light weight

- > Easy installation by epoxy resin or bolt

- > Improve your working environment - noise, vibration and safety

3. Product Specification:

- - Square tile: 10x10x3~10mm, 17.5x17.5x3~15mm, 20x20x3~15mm, etc.

- - Ceramic Plate: 100x100x6~50mm, 150x100x6~50mm, etc.

- - Hexagonal tile: S12.5xT3~20mm, S23.5xT6-25mm

- - Dimple tiles: 20x20x4-10+1(with 5 dimples), 20x30x5~15+1(with 18 dimples), 20x20x5-10mm( with 13 dimples)

- - Ceramic Block: 40x40x40mm, 45x45x50mm,32x32x22mm, 38x38x38mm, etc.

- - Ceramic Cylinder/rod: 6x6mm,15x15mm,20x20mm, 31x31mm,40x40mm, 45x50mm, 50x50mm etc.

Detailed Photos

Product Parameters

| Category | HC90 | HC92 | HC95 | HCT95 | HC99 | HC-ZTA | ZrO2 |

|---|---|---|---|---|---|---|---|

| Al2O3 | ≥90% | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | / | ≥21% | ≥95% |

| Density | >3.50g/ cm3 | >3.60g/cm3 | >3.65g/cm3 | >3.70g/cm3 | >3.83g/cm3 | >4.10g/cm3 | >5.90g/cm3 |

| HV 20 | ≥900 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| Rock Hardness HRA | ≥80 | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Bending Strength MPa | ≥180 | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Compression strength MPa | ≥970 | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Fracture Toughness KIc MPam 1/2 | ≥3.5 | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Wear Volume | ≤0.28 cm3 | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 | ≤0.10 cm3 | ≤0.05cm3 | ≤0.02cm3 |

${currentPro.title}