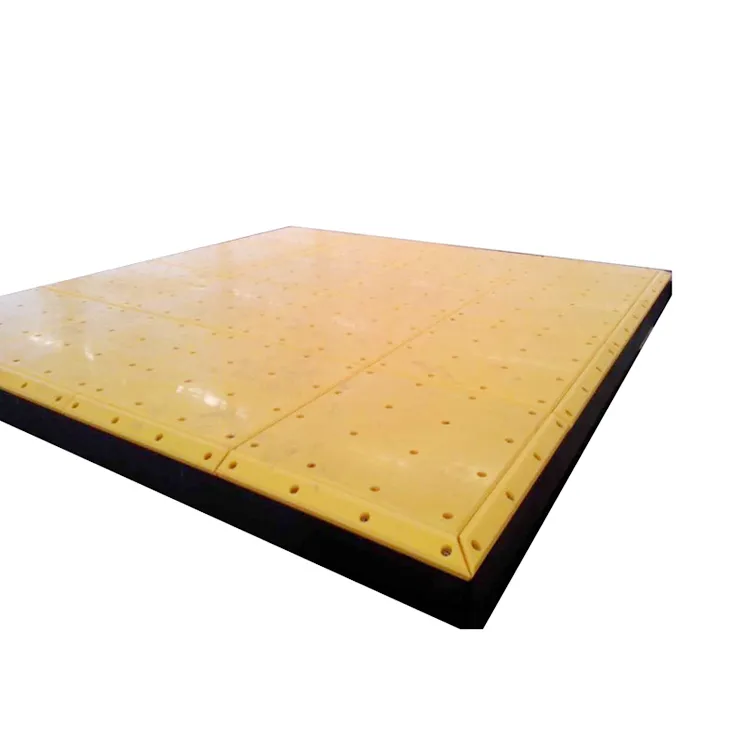

Marine Fender Face Pad: HDPE UHMWPE Sliding Panel for Boating Protection

Description

Overview

Basic Info.

| Model NO. | Marine Fender Facing Pads |

| Material | PE |

| Kind | Engineering Plastic Sheet |

| Water Absorption | <0.01% |

| Contraction Percentage | 2.0%~5.0% |

| Tensile Strength | 81~130MPa |

| Certificates | ISO CE SGS |

| Thickness | 3mm-300mm |

| Accessories | Bolts or Welding |

| UV Resistance | Yes |

| Compression Strength | 30MPa |

| Shore Hardness | Shore D 65 |

| Transport Package | Wooden Pallet |

| Specification | Customized size |

| Origin | China |

| HS Code | 3920109090 |

| Production Capacity | 6000tons Per Year |

Packaging & Delivery

| Package Size | 1000.00cm * 1000.00cm * 1000.00cm |

| Package Gross Weight | 100.000kg |

Product Description

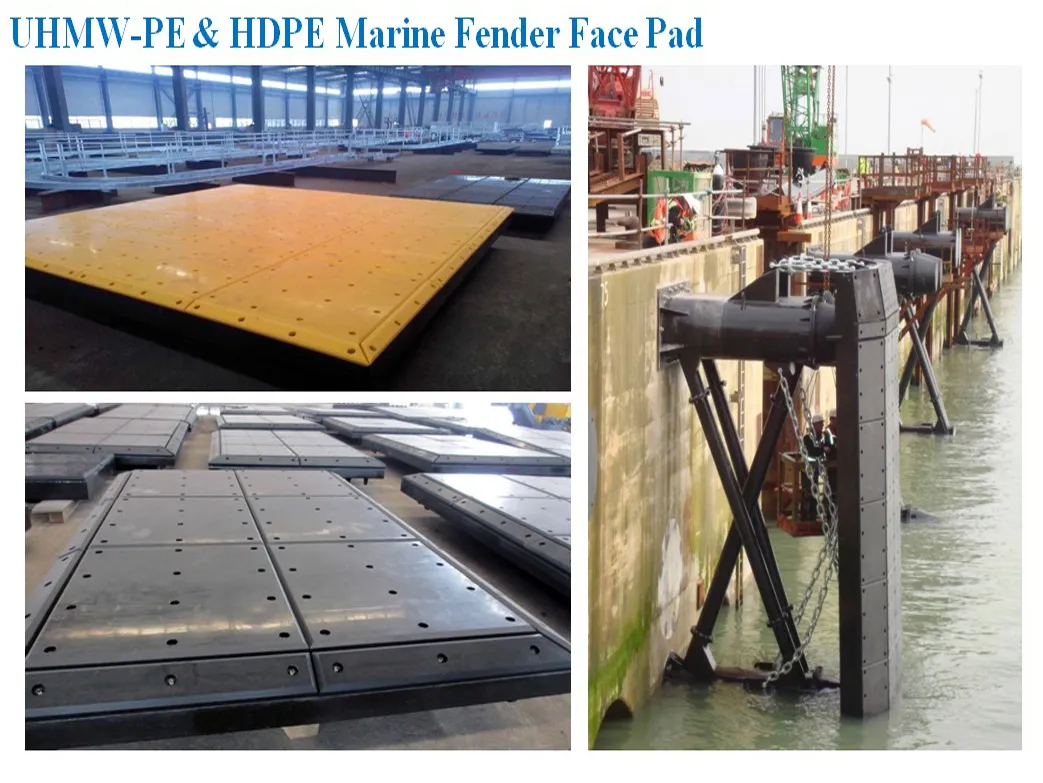

UHMWPE sliding panel marine fender face/facing pads. Traditional dock fender panels are made of UHMWPE material sheets. Although they are durable, they are not easily damaged when the ship is docked. UHMWPE fender pad replaces traditional marine fenders. They are durable and more flexible. They can better protect the dock and the ship's body.

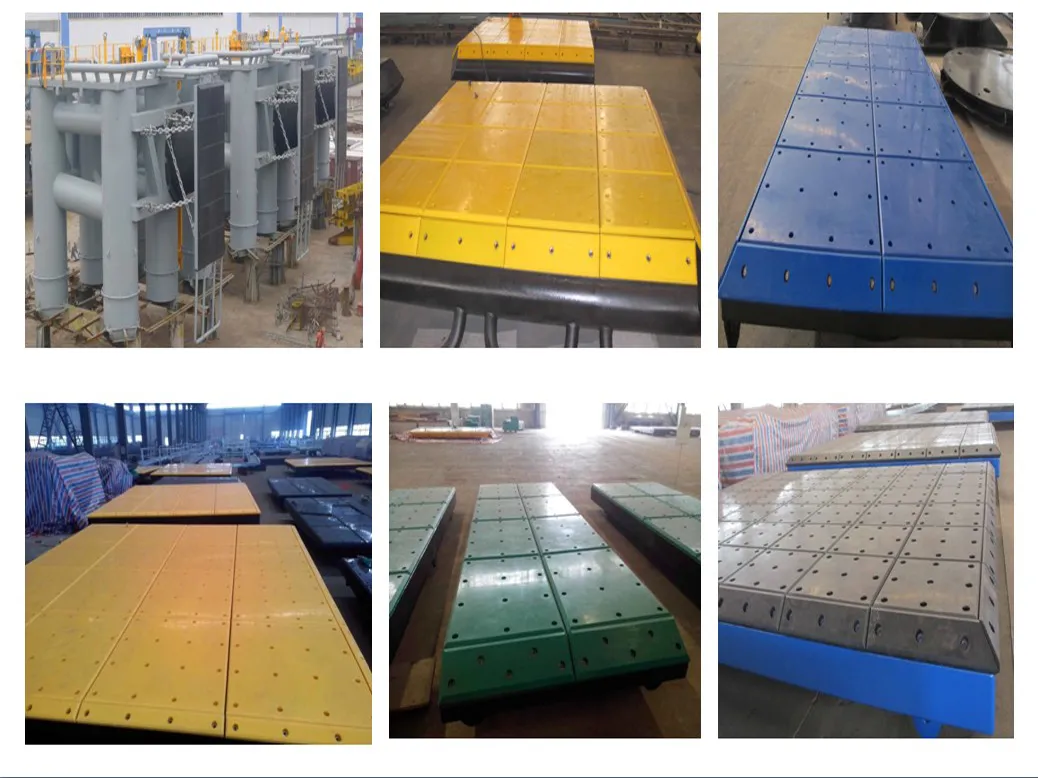

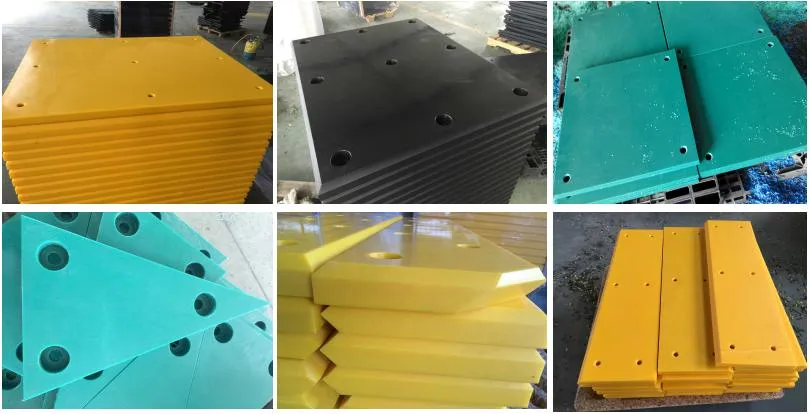

UHMWPE material products possess a low coefficient of friction, which provides a smooth sliding surface for the vessels to travel along the fender face. Our UHMWPE comes in many colors and thicknesses, according to project requirements. UHMWPE can also be supplied in stand-alone applications that are not related to rubber fenders for sliding surfaces that do not require any energy absorption.

Detailed Photos

Advantages & Key Features:

- Highest abrasion resistance of any polymer, 6 times more wear resistant than steel

- Anti-Weather & Anti-Aging

- Self-lubricating, Very low coefficient of friction

- Excellent chemical & corrosion resistant

- superior impact resistant, Noise- absorption, Vibration-absorption

- Temperature range: -260°C ~ +80°C; Very high resistance to cold, doesn't become fragile even under -180°C

- High tensile Strength

- Non-Toxic and smell

- UV resistance

- Flame Retardant; Relatively low in water absorption

- Excellent electrical properties

- Good performance in resisting environment stress crack, 200 times of ordinary PE

- No adhesion

- Light weight and easier to handle and fix

- Cost efficient; Resulting in low energy consumption

- Does not rot, split or crack; 100% recyclable

- Great liner material for industrial material handling applications

- Easy Reprocessed

Product Parameters

| Project Name | Unit | Test Method | Test Result |

|---|---|---|---|

| Density | g/cm³ | ASTM D-1505 | 0.94-0.98 |

| CompressIve Strength | Mpa | ASTM D-638 | ≥42 |

| Water Absorption | % | ASTM D-570 | |

| Impact Strength | KJ/m² | ASTM D-256 | ≥140 |

| Heat distortion temperature | ºC | ASTM D-648 | 85 |

| Shore Harness | Shore D | ASTM D-2240 | >40 |

| Friction coefficient | ASTM D-1894 | 0.11-0.17 |

Packaging & Shipping

${currentPro.title}