Hot Runner System Injection Mold for Plastic Automotive Components

Description

Overview

Basic Info.

- Model NO. HW-378

- Certification ISO

- Shaping Mode Injection Mould

- Plastic Material ABS

- Process Combination Type Single-Process Mode

- Runner Hot Runner

- Design Software Ug

- Installation Fixed

- Standard Hasco

- Customized Customized

- Surface Finish Process Texture or High Gloss Polishing

- Mould Cavity Single Cavity or Multi Cavity

- Transport Package Exported Wooden Box, Fumigation Upon Required

- Specification According to your drawing

- Trademark HOWE or Custom

- Origin China

- HS Code 8522901000

- Production Capacity 8000PCS/Day

Packaging & Delivery

- Package Size 45.00cm * 45.00cm * 38.00cm

- Package Gross Weight 11.000kg

Product Description

Hot runner system injection mold for various plastic automotive components

Mold information

- Parts Material ABS, PP, PC, PE, PA, PS, POM, Rubber, Silicone, etc

- Tooling standard FUTABA, LKM, HASCO, DME

- Moldbase steel 45#, 50#, P20, H13, 718 2738, NAK80, S136, SKD61, etc

- Runner Cold / Hot runner

- Cavity Multi or single cavity

- Gate type Side gate, Sub gate, Pin point gate, Edge gate, etc

- Surface Finish Texture or high gloss polishing

- Mold lifespan 1,000-1,000,000 shots

- Mold weight 50~10,000kg

- Equipment High speed CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine from 50-1000T

- Packaging & Shipping For Parts: exported carton box. For Mold: exported wooden box, fumigation upon required

- Delivery time T1, approx 20~50 days, parts measurement report optional

Custom Plastic Injection Molding Applications:

- Plastic injection molding parts for architectural parts

- Plastic injection molded auto components

- Injection-molded household utility products

- Plastic molded electronic enclosures

- Plastic molds for medical & dental products

- Injection molding parts for model shops, toys

- Injection plastic parts for new product design & development

- Custom plastic parts for construction

- Injection plastic parts for others like cosmetic case

- Plastic injection for Information Technology

- Molded plastic parts for payment system

- Precision plastic parts for Agricultural equipment

Mould Trade Process

- Receive RFQ (drawings, samples or requirements), start quotation. >> DFM, design concept and mould flow analysis if required.

- Approval of mold design with agreement on all details including: HASCO/DME, cycle time, hot runner, tool life, steel, etc. Every component will be under control based on final design during fabrication.

- Update CPP to customer on a weekly basis along with pictures.

- First article inspection report with samples to customers after mould trials. Adjustment of out-of-spec dimensions until all criteria of the tool are met.

- Professional document preparation ensures that your project can be transferred to effective production.

- If samples and tool approved by customer, we can make 4~48h automatic tool run with video on demand, and offer tooling evaluation report with processing data to customer before shipment.

- Arrange tool shipment as Door to Door, or Door to Port delivery service.

- Packed by steel box or wood box.

- Pack final samples, spare parts, user guide, etc.

- Aftersales service

- 12 months warranty

- Guarantee mold life as per SPI standard or customer specified.

- Some spare parts of mold for free.

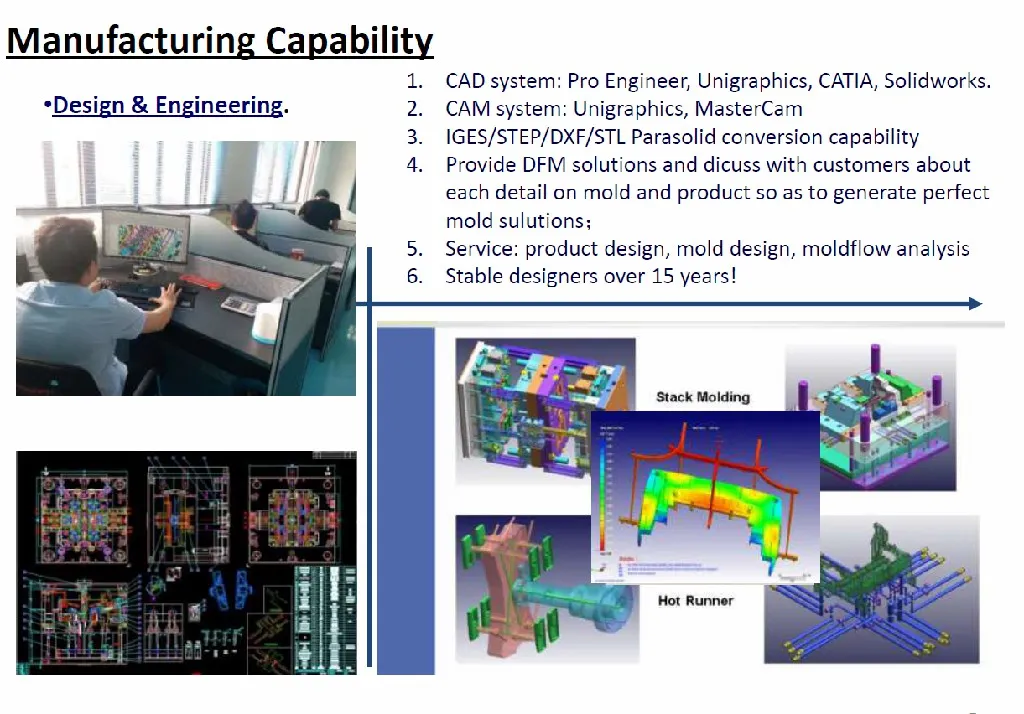

Company Profile

Dongguan Howe Precision Mold Co., Ltd with around 2,000sqm work shop locates in Chang'an Town, Dong Guan City, Guang Dong Province, China. Which was established at the beginning of 2010 and it's only one and a half hour's drive from the airport/ ferry port in Hong Kong, Guang Zhou and Shen Zhen to our factory. Our moulds are mainly exported to USA, Canada, Brazil, UK, Germany, Spain and Japan etc., We have more than 13 years experience in building all kinds of plastic molds & die casting molds and manufacturing products. Capability of design, level of manufacturing, and mould quality system and company target can meet the demands of various customers. Our molds annual capacity is up to 500sets. Main moulds cover large automobile components, home electric appliances, electric garden tools, medical treatment equipment, computer peripheral parts, telescopes, plastic pipe for drink-water machines, two colour moulds, etc.

Our factory is equipped with advanced equipment: CNC machines, the machining range is (550mm - 5000mm), EDM machines, the machining range is (300mm - 3000mm), High speed CNC machines, CMM, wire-cut machines, numerical controlled lathers, milling machines, large-size drilling machines, grinding machines, and deep-hole drilling machines. We can also provide mold trial and plastic injection with 50 tons to 2880 tons of Injection Machine and 3600 tons of Plastic Injection Machine.

HOWE Mold Work Shop

Process of making moulds

- Sample/Drawing: After receiving your detail information like 2D & 3D drawings or sample for reference, will pass to the R&D team to do Moldflow analysis.

- Negotiation: Material, cavity, price, delivery time, payment term etc.

- Place Order: when all terms are agreed by both sides, then we will accept an order.

- Mould Design: Our R&D team will design the mould per customer requirements and send drawings for approval.

- Tooling Mould: Once the mould design is approved will start mould tooling.

- Mould Process: CNC grinding and milling, Heat Treatment, Wire Cut, Polish, Tool assembling and testing etc. Our good QC system can guarantee the product quality.

- Sample Confirmation: Send samples for confirmation, if not approved we will adjust the mould structure.

- Mass Production: After the customer approves the sample, we will arrange mass production. QC will inspect after products finished.

- Package: PE film for plastic parts, wooden case for moulds or as customer's requirement. QC will inspect packing.

- Delivery: By sea or by air according to customer requirements.

- After-sales Service: Ready to help customers solve any possible problems.

${currentPro.title}