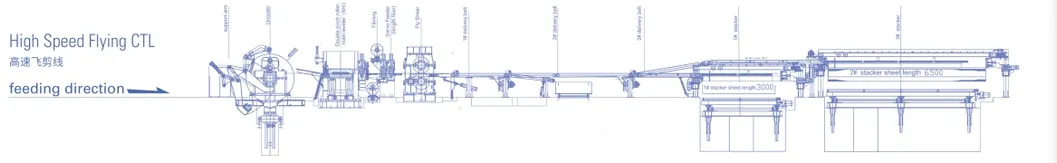

High-Speed Metal Sheet Processing Line

Description

Overview

Basic Info.

- Model NO. ST0.15-1.0 *1000

- Automation Automatic

- After-sales Service Installation

- Model No St0.15-1.0 *1000

- Coils Materials Mild /Aluminum /Stainless/Copper /Silicon Steel

- Coil Width 200-1000mm

- Coil Thickness 0.5-1.0mm

- Coil Weight 10t

- Sheet Flatness <1.0mm/Square

- Line Speed 0-60-80m/Min

- Cut Length Precisionion <0.25mm/2m

- Diagonal Precision <0.25mm/2m

- Transport Package Suit for Sea

- Specification ST0.15-1.0 *1000

- Trademark ST

- Origin China

- HS Code 84623910

- Production Capacity 150 Sets Per Year

Packaging & Delivery

- Package Size 300.00cm * 200.00cm * 100.00cm

- Package Gross Weight 200.000kg

Product Description

St0.15-1.0 *1000 Metal Sheets Cut to Length Leveling Cutting Mahine Line & Shearing Machine&Slitting Machine Line Factory

This is a detailed PROFESSIONAL introduction about the steel coil slitting machine, including its introduction, core components, workflow, and application areas. The steel coil slitting machine is a key equipment in the metal processing industry, specifically used to continuously cut large rolls of wide steel strips (steel coils) into multiple narrow strips of the required width, and re roll the cut narrow strips into independent coils for subsequent use. The steel coil slitting machine is a heavy-duty, high-precision industrial equipment that combines mechanical, hydraulic, electrical, and automation control technologies to efficiently process various specifications of steel from thin to thick plates (such as cold-rolled plates, hot-rolled plates, galvanized plates, stainless steel plates, silicon steel sheets, etc.). Its core task is not only simple slitting, but more importantly, to ensure the dimensional accuracy, edge quality (no burrs, less flanging), and winding neatness (tower shape, tightness) of the sliced strip steel.

Core components

Production process flow

- Loading Car & Uncoiler: ·The hydraulic feeding trolley is used to carry and lift heavy steel coils, and accurately align them onto the reel of the unwinding machine. ·The reel of the uncoiler is fixed to the steel core by expansion and provides post tension. Usually equipped with pressure rollers and scrapers to prevent steel coils from loosening and scratching.

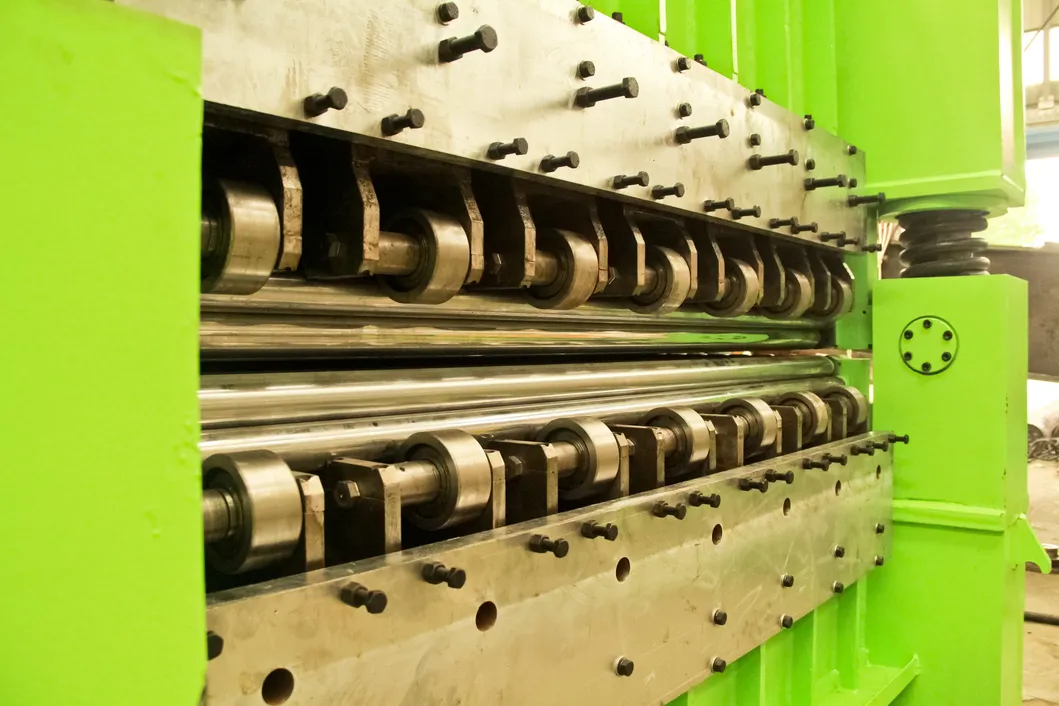

- Leveling Unit: ·This is a key component to ensure quality. Usually composed of multiple sets of staggered straightening rollers. ·Its function is to eliminate plate shape defects such as sickle bends, waves, warping, etc. that occur during the previous rolling and coiling processes of steel coils, ensuring that the steel plate enters the slitting area flat.

- Guidance & Centering System: ·Using photoelectric or hydraulic servo centering devices, the edge position of the strip steel is monitored in real time and automatically adjusted to prevent material deviation and ensure absolute accuracy of the strip width.

- Slitting Unit: ·Using circular cutting method. This is the only way to strip steel coils. ·Composed of a pair of overlapping disc cutters (slitting cutters) that rotate in opposite directions. The overlap and lateral clearance between the upper and lower blades are key parameters that determine the cutting quality and tool life, and need to be precisely adjusted according to the thickness and material of the board. ·The blade axis system is usually cantilevered or through axis, which facilitates quick replacement and adjustment of blade spacing (width setting).

- Scrap Winders: ·Used for winding and cutting waste materials generated on both sides (if the mother roll is not fully utilized), to maintain the cleanliness and continuous operation of the production line.

- Tension Control System: ·By using servo motors or vector frequency converters, the tension of the entire process from unwinding, slitting to winding can be precisely controlled. Stable tension is the fundamental guarantee for neat and compact winding without looseness or collapse.

- Rewinder: ·Adopting a central winding method, the core is driven to rotate by the spindle. ·Usually equipped with a belt coiler or hydraulic coiler arm, the head of the strip steel is pressed onto the core at the beginning of winding to achieve smooth coiling. ·The advanced equipment is equipped with an EPC (Edge Position Control) system, which moves the winding axis slightly left and right during winding to ensure that the multiple narrow strips are wound neatly after slitting, avoiding the occurrence of "tower shaped" rolls.

- Unloading Car: ·After the winding is completed, receive and remove heavy finished roll materials.

- Control System: ·Using PLC as the core and integrating HMI (human-machine interface touch screen). The operator can preset parameters such as strip width, quantity, tension, and speed, and the system automatically completes all actions and achieves fault diagnosis and data recording.

Main application areas

- Metal Products Industry: ·Pipe making: raw materials for producing welded pipes (such as water pipes, gas pipes, scaffolding pipes). ·Profile and Cold Bending Forming: Used for manufacturing cold bending profiles such as shelves, guardrails, C-shaped steel, Z-shaped steel, and automotive guide rails. ·Louvers and anti-theft nets: Cut steel strips into various narrow strips.

- Household Appliance Industry: ·Provide segmented sheet metal for the exterior and internal structural components of household appliances such as refrigerators, air conditioners, washing machines, and microwave ovens.

- Automotive Industry: ·Produce automotive components such as sealing strip frames, seat rails, various structural reinforcements, etc.

- Electrical Industry: ·Cut silicon steel coils into sheets for manufacturing transformer, motor, and generator iron cores. ·Cut cable armor tape.

- Construction Industry: ·Provide raw materials for floor slabs, color steel tiles, etc.

summary: The steel coil slitting machine is the "cutting master" of modern metal processing industry. It efficiently and accurately processes large coil raw materials into specific specifications required by downstream industries, and is an indispensable key link connecting steel smelting and rolling with terminal product manufacturing. Its technical level directly determines the quality, cost, and production efficiency of the final product.

Product Parameters

| Type | ST 1000 | ST-1100 | ST-1250 | ST-1600 | ST-1600 | ST-1800 |

|---|---|---|---|---|---|---|

| coil thickness | 0.15mm-1.0mm | 0.2mm-2.0mm | 0.3mm-3.0mm | 0.4mm-4.0mm | 1.0-6.0mm | 2.0-8.0mm |

| coil width | 200-1000mm | 300-1100mm | 300-1250mm | 500-1600mm | 500-1600mm | 800-1800mm |

| coil weight | 10ton | 12ton | 15ton | 20ton | 25ton | 30ton |

| Machine speed | 0-60-80m/min | 0-60-80m/min | 0-60-80m/min | 0-60-80m/min | 0-30-60-80m/min | 0-30-50m/min |

Detailed Photos

After Sales Service

We provide comprehensive After Sales Support and Service to meet our customer need.- Drawings: Provide the foundation drawing, electric scheme and wiring diagram, hydraulic drawing, pneumatic & electric pipeline drawing and other drawings requested by customer.- Installation and commissioning: Will send our technicians to customer's workshop for supervision of installation and commissionTraining of Customers' technician/workers during commission- Breakdown Support: We offer 1 year warranty service for main crucial components except consumablesInform immediate technical assistance and advice to customer by phone or e-mail.Skilled and experienced engineers are capable of dealing with any type of breakdowns.Technical service work performed in Customer's site if required.Urgently supply mechanical or electronic components.Fast supply of spare parts and wearing parts to cover foreseeable requirements

${currentPro.title}