High Productivity Sheet Metal Coil Slitting Processing Line

Description

Overview

FAQ

Overview

Basic Info.

- Model NO. LM-SL-YS050

- Power Source Electric

- Feature Automation

- Customized Customized

- Advantage Use Widely

- Condition New

- Ingredients Material Cold Rolled Coil, Galvanized Coil

- Thickness 0.3mm-3.0mm

- Breadth 300mm-1300mm

- Minimum Stripe Width 20mm

- Waste Edge Width 2mm~5mm

- Speed 0~200m/Min

- Floor Space 23m Long X 7m Wide

- Transport Package Fob

- Trademark RFM

- Origin Hebei

- Production Capacity 100set of/1year

Packaging & Delivery

- Package Size 300.00cm * 80.00cm * 100.00cm

- Package Gross Weight 6000.000kg

Product Description

Factory with 27 years of manufacturing experience. Suitable for all kinds of material strip, material thickness can be 0.3mm-3.0mm.

Type

- LM-450

- LM-650

- LM-1000

- LM-1250

Slitting material

- Plain carbon steel, stainless steel, copper, aluminum and alloy

Slitting width

- Max 450mm

- 200~600mm

- 500~1000mm

- 600~1250mm

Material thickness

- 0.2~1.5mm

- 1.0~5.0mm

- 0.5~3.0mm

- 1.0~3.0mm

Slitting speed

- 10~90m/min

- 1.0~1.5mm ≤100m/min

- 0.5~1.0mm ≤100m/min

- 1.0~2.0mm ≤80m/min

- 1.5~3.0mm ≤90m/min

- 1.0~2.0mm ≤100m/min

- 2.0~3.0mm ≤60m/min

- 3.0~5.0mm ≤80m/min

- 2.0~3.0mm ≤80m/min

Slitting quantity

- ≤12strips

- ≤25strips

- ≤20strips

- ≤3strips

Weight of the winder reel

- Max 2.5T

- Max 3.5T

- Max 3.0T

- Max 5.0T

FAQ

Frequently Asked Questions

Q1. How do I choose the right machine for me?

1. A machine does not just provide a few photos to prove what it can produce.

2. A machine should have photos and videos of the complete production and assembly system.

When choosing a factory, it is important to make sure that the company has a complete production and service system.

Contact us for machine production and assembly videos.

Q2. You don't show the product I need, can you produce it?

Our company's engineers have studied in famous cold bending companies in Europe, and we have a great advantage in machine design and R&D manufacturing.

Q3. How long does it take to build the machine?

Generally speaking, it takes about 75-90 days for the machine to be completed, if you need the machine urgently, we can make it urgently because our company has a large number of spare parts.

Q4. Why are your prices higher than others?

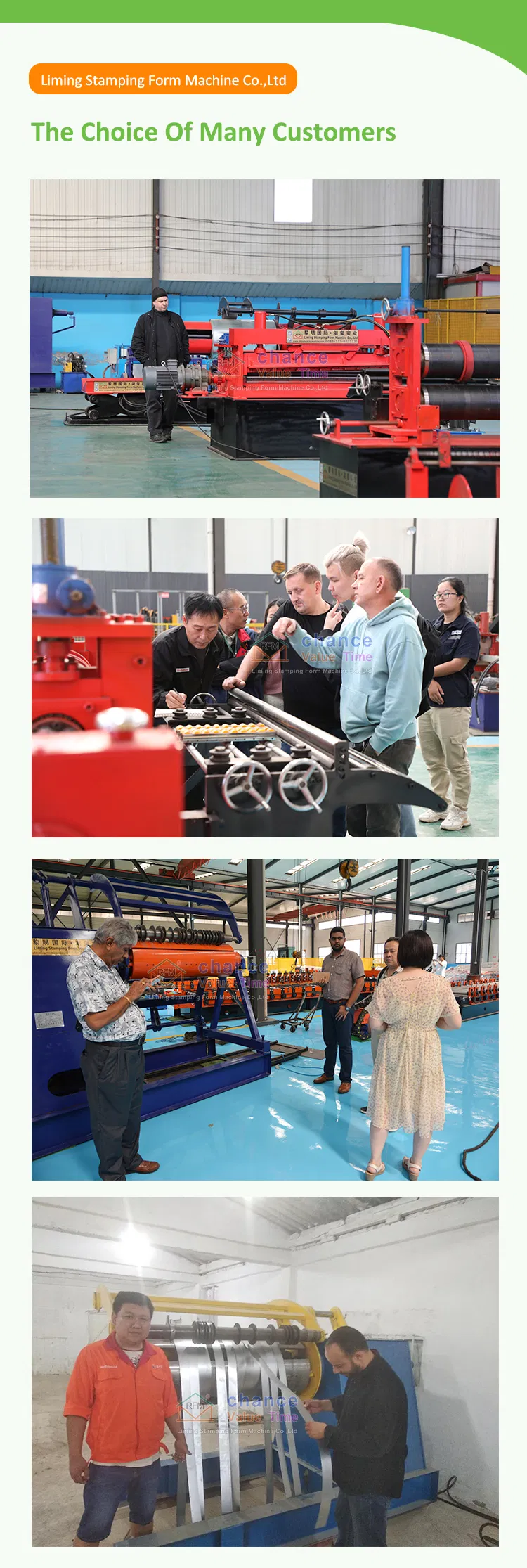

Because we insist that every factory should put quality in the first place, low price means giving up quality, we won't produce poor quality machines, so the machines we produce have a long service life, we have many old customers.

Our machines can be used for nearly 20 years and we provide lifetime after-sales service. (Engineer can come to your home for maintenance)

Q5. Do you have after-sales service support?

Product quality is the first priority, and the best after-sales service is that customers keep referring customers.

We have 27 years of production experience, and our strong strength guarantees that we are a company with after-sales service.

Q6. How do I get a quote?

1. Engineers need to know the coil width, coil thickness, and coil weight; this is important.

2. If you have requirements for production speed, power, voltage and brand, please specify in advance.

${currentPro.title}