Automatic Sheet Metal Processing Line for 0.2-6.0mm Thickness

Description

Overview

Basic Info

Process Usage

Metal-Cutting CNC Machine Tools

Numerical Control

CNC

Performance Classification

High-End CNC Machine Tools

Certification

CE, ISO 9001

Condition

New

Delivery

5-6 month

Coil Thickness

Max. 0.4-1.8 mm

Coil Weight

Max. 20000 kg

Circle Diameter

Max. 85-660 mm

Burr

0.1*T (T=0.5~1.0 mm)

Leveling Speed

0-60 m/Min

Feeding Speed

0-60 m/Min

Press Machine Speed

15-60 spm

Transport Package

Suitable Package

Specification

Coil width Max. 800-2000 mm

Trademark

AI-MACHINE

Origin

China

Product Description

Product Description

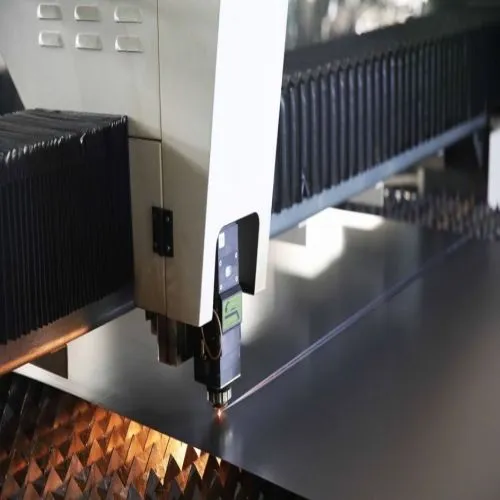

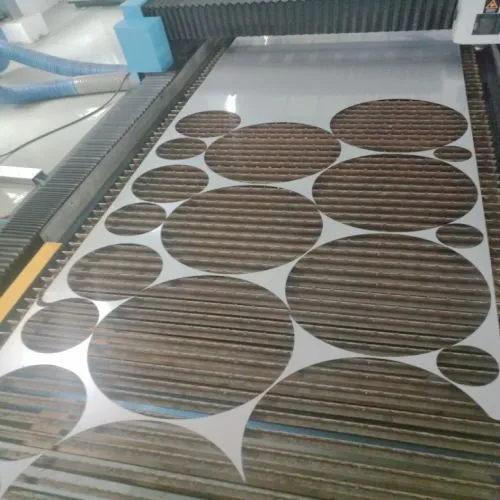

Our laser blanking line uses a laser cutting machine to fly cut (follow cutting) during the movement of the strip. The purpose is to solve the problem of rapid cutting of continuous metal and non-metallic strips without molds, in order to reduce the investment and mold consumption costs of the equipment, and effectively improve the utilization rate of materials.

Low equipment investment: has lower quality, lower energy consumption, and does not require complex equipment foundations, greatly reducing the initial investment and later maintenance costs.

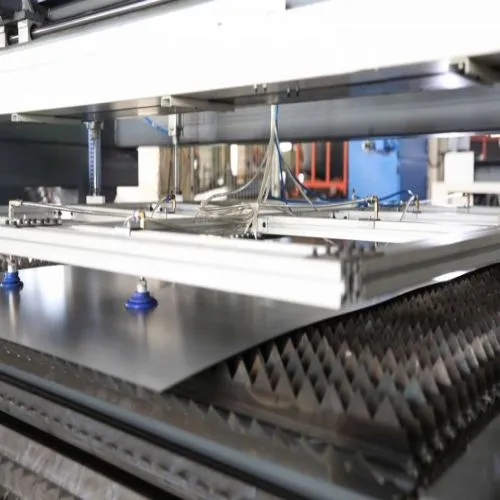

High output efficiency: uses coils for blank production, replacing the production process of slicing coils first and then cutting them on the equipment, improving production efficiency.

High flexibility: No need to manufacture molds, advanced layout software and control system are used, and product specifications and shapes can be quickly converted, making it suitable for various batch production.

Low maintenance cost: using fiber laser cutters for reliable performance; At the same time, laser cutting speed is fast, and the cutting speed of stainless steel can reach 40 meters per minute (when the thickness is 1mm), which can quickly complete cutting and cutting.

High product quality: Adopting high-precision leveling machines, high-precision feeding and cutting systems, advanced automatic stacking systems, etc., it can adapt to the production of various metal material parts and blanks.

Low cost of use: no need for molds for stamping, the cost of mold manufacturing and maintenance is reduced; At the same time, the equipment does not use a large press, greatly reducing production energy consumption and reducing environmental noise.

High material utilization rate: because continuous production is carried out using coil materials, there will be no loss of material head and tail during single chip production; At the same time, the equipment adopts optimized layout, combining various shapes of parts for edge free cutting, reducing material loss and improving material utilization rate.

Product Parameters

| Parameter | Scrape | Unit | ||

|---|---|---|---|---|

| Coil width | 200-700 | 600-1250 | 800-2000 | mm |

| Coil thickness | 0.4-1.8 | 0.4-1.8 | 0.4-1.8 | mm |

| Coil weight | 5000 | 10000 | 20000 | kg |

| Circle diameter | 60-500 | 85-660 | 85-660 | mm |

| Strokes | 20-90 | 20-60 | 20-60 | spm |

| Rated tonnage | 2000 | 2500 | 2500 | KN |

${currentPro.title}