Evaporation Plastic Vacuum Coating Machine for ABS PS PP PC PVC/Plastic

Description

Overview

Basic Info.

| Model NO. | RM-1500/1600/1800 |

| Type | Coating Production Line |

| Coating | Vacuum Coating |

| Substrate | Steel |

| Certification | CE |

| Condition | New |

| Transport Package | Export |

| Origin | China |

| Production Capacity | 2 sets/Day |

Packaging & Delivery

| Package Size | 100.00cm * 100.00cm * 100.00cm |

| Package Gross Weight | 1000.000kg |

Product Description

The pre-vacuum unit automatically performs continuous low-vacuum exhaust, followed by glow discharge to pre-treat the product to enhance surface cleanliness, followed by high vacuum exhaust (X10-3) at high power Flashing under the action of evaporation power, and then ionizing HMDSO under the action of DC step-up transformer, obtaining SiOx/NOS protective layer, making the aluminum ring antioxidation, corrosion resistance, friction resistance, high-temperature resistance and high reflectivity. The super-hard protective film improves the nitriding resistance of the aluminum layer and maintains the high reflectivity of the aluminum layer for a long time.

Compared with the intermediate-frequency power supply device, the DC boost requires a longer glow discharge and protective film ionization time, but the protective film of the depth piece will work better. In addition, the comfortable human-machine interface and data transmission system enhance the management efficiency of the device.

Product Parameters

| Model | RM-1500 | RM -1600/1800 |

|---|---|---|

| Furnace size | Φ1500 mm * H1980 mm | Φ1600(1800) mm * H1980mm |

| Furnace | Vertical double door | Vertical double door |

| Revolving design | 6 x Ø 530(540) | 6 x Ø 530(540) |

| 8 x Ø 420(430) | 8 x Ø 420(430) | |

| Coating area | 15.2 m² (coating height 1.6 m) | 15.2 m² (coating height 1.63 m) |

| Estimated furnace time | 10-12 min | 10-14 min |

| Machine footprint | 6800mm×70000mm ×3100mm | 7000 mm×7000mm ×3100mm |

| Control System | Touch screen (or industrial computer) + PLC, Real-time monitoring of big data | Touch screen (or industrial computer) + PLC, Real-time monitoring of big data |

| Coating Technology | Glow discharge, Evaporated aluminum plating, Plasma chemical vapor deposition, SiOx/NOS protective layer, IF (US AE), Cryogenic -140 ° C | Glow discharge, Evaporated aluminum plating, Plasma chemical vapor deposition, SiOx/NOS protective layer, IF (US AE), Cryogenic -140 ° C |

Note: Our company can be customized according to customer's products and special process requirements.

Advantage

- Over 3000 plants installed worldwide

- Quick cycle times

- High production capability with low energy consumption

- More uptime due to ease of loading/unloading and low maintenance

- High productivity with only a single operator

- Steel process chambers, built to last

- Eco-friendly

- Space-saving design

- PVD option available on all plants

- 1-year component warranty and 25 years minimum guaranteed working life

- Complete global network of consulting, engineering, and renowned after sales service

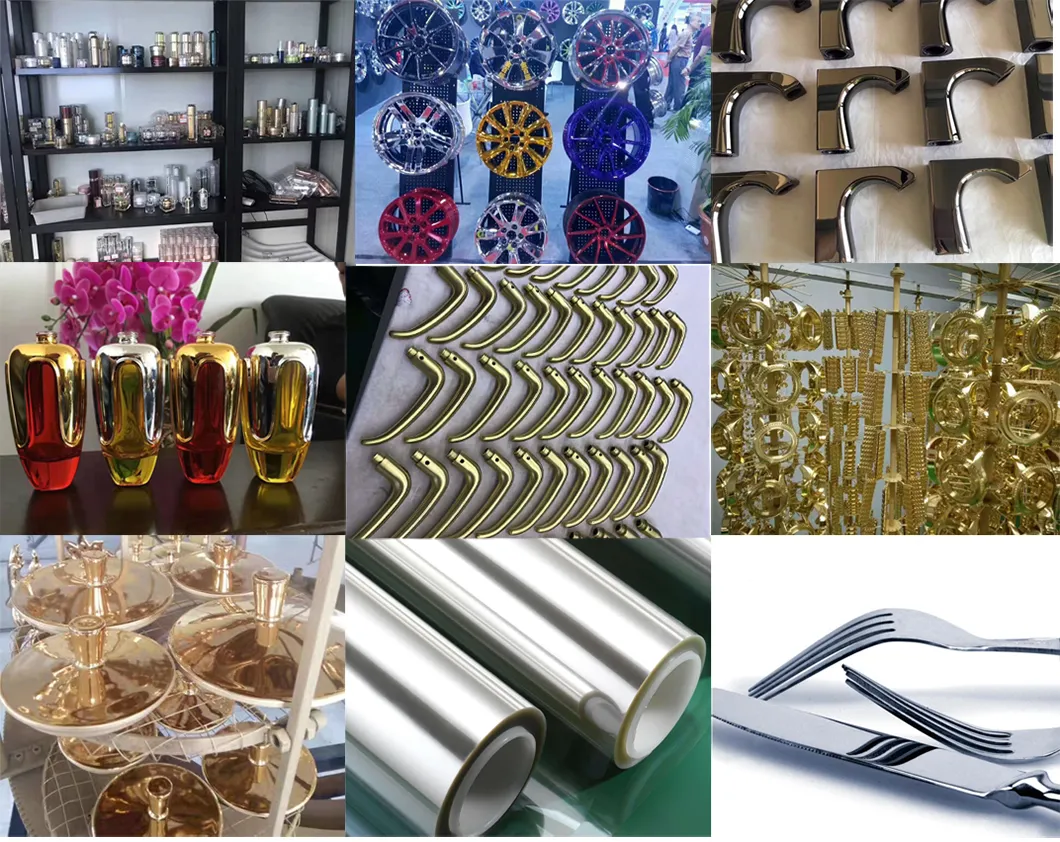

Application

Automotive lighting reflectors, front lights, rear lights, turn signals, license plate lights, etc. The front lights include: tungsten halogen lamp, xenon lamp, low beam lamp, high beam lamp, front turn signal, front position lamp (also called width lamp, indicating the position of the vehicle), front fog lamp. Rear lights include rear position lights, reversing lights, brake lights, rear fog lights, rear turn signals.

${currentPro.title}