Customized Heavy Duty Gravity Motorized Conveyor Belt Steel Conveyor Roller

Description

Basic Info.

Packaging & Delivery

Product Description

CONVEYOR ROLLERS,CONVEYOR IDLERS,CONVEYOR SPARE PARTS, CONVEYOR DRUMS PULLEYS

FOR BULK MATERIAL HANDLING PROJECTS

Main features:

1. Solid design, most suitable for heavy lifting.

2. The bearing housing and steel tube are assembled and welded with a concentric automatic,welding machine.

3. Cutting of the steel tube and bearing is performed with the use of a digital auto device/ machina/equipment.

4. The bearing end is constructed to ensure that the roller shaft and bearing can be firmly connected.

5. Fabrication of the roller is effected by an auto device and 100% tested for its concentricity.

6. Roller and supporting components/materials are manufactured to DIN/AFNOR/FEM/ASTM/CEMA standard.

7. The casing is manufactured with highly composite, anti corrosive alloy.

8. The roller is lubricated and free from maintenance.

9. Working life expectancy is up to 30,000 hours or more, depending on usage.

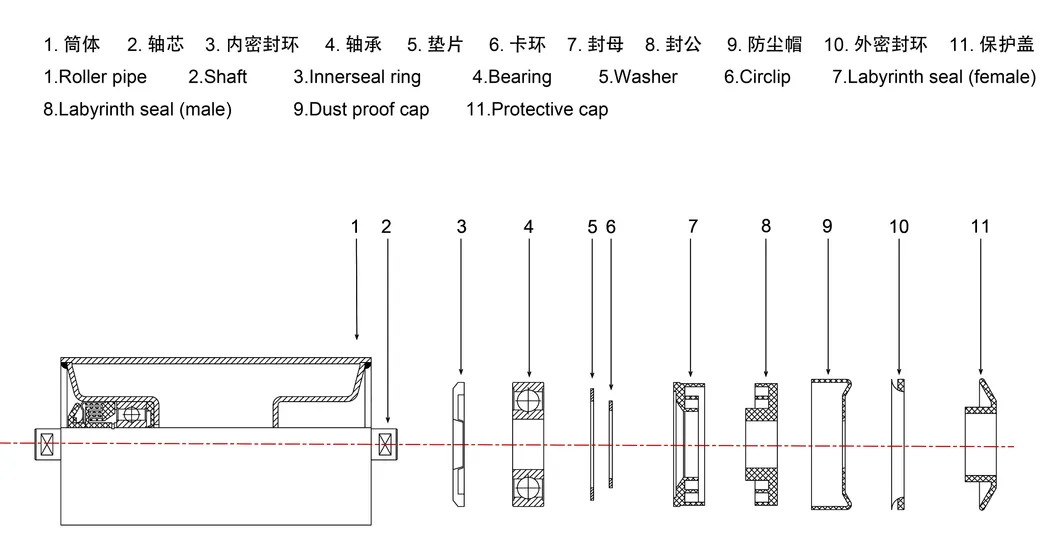

10. Vacuum sealed with: inner-seal, 3 slot labyrinth seal, V shape rubber ring and eccentrically autocleaning body which has withstood anti water, salt, snuff, sandstone and dust proof experiments.

raw materials and specifications

| Axle(shaft) | cold-draw steel ST ST37DINI7100,E24 AFNOR NFA 35501. |

| Rod | 2 0.2 25.2 30.2 40.2 lSO hll accuracy fine polished to 20,25, 30, 40 levels on the universal sealed bearing packaging area. The precision attained isISO h6. |

| Steel roll | welded with DlN2394 standard, components are ST37 to fit DlN17100 standard. |

| Bearing housing | cold press working fit lSO M7 accuracy deep press steel with raw material fit DIN1623-1624 standard. |

| Inner seal circle | lip-lining sealed, component is made of NYLON6 (ISO Pa6). |

| Bearing | trough type, deep groove ball bearing (Wind age level C3) DlN 6263 series. |

| Labyrinth seal circle | 3 troughs, component is made of NYLON6 (ISO Pa6). |

| Housing/cover | deep press steel fit DlNl623-1624 standard. |

| Outer seal circle | sliding rubber ring with V shape, components are nitrosation rubbers which are long lasting, wear resistant, and antioxidant. |

| Function of protecting cover | used to protect the roller from axial vibration, made by copper alloy which is anticorrosive. |

| Lubricating oil | to ensure the roller bearing is lubricated continuously, using 2, 3 grade long-lasting lithium grease. |

lt contains threelayers of dust proof structure each fabricated with long lasting rubber seals which can effectively prevent penetration by dust and water.lt generates a high volume,high speed,conveyor belt system resulting.In the design of multiple components.

Welded quality

Roller and bearing housing are welded using an advance,automatic, circular welding machine. The welding process can effectively prevent dust and water from entering the spaces /gap between roller and bearing housing.Also,the smooth surface left by the weld can minimize belt damage.

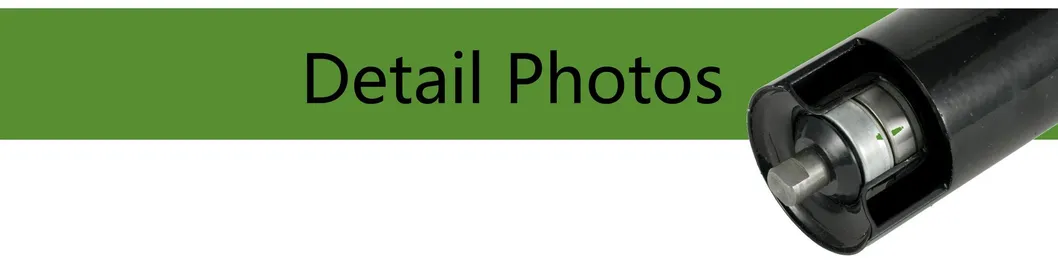

Bearing and Bearing Housing

All rollers use high quality ball bearings with deep grooves.The bearing housing is shaped through various stages of precision stamping(pressing,forging),to efficiently connect to the bearing cover part.lt needs only to be assembled once,with the various sealed components,which increases the effectiveness of the seal whilst,at the sametime,decreasing the(spinning)impediments to theroller.(enhancing concentricity)

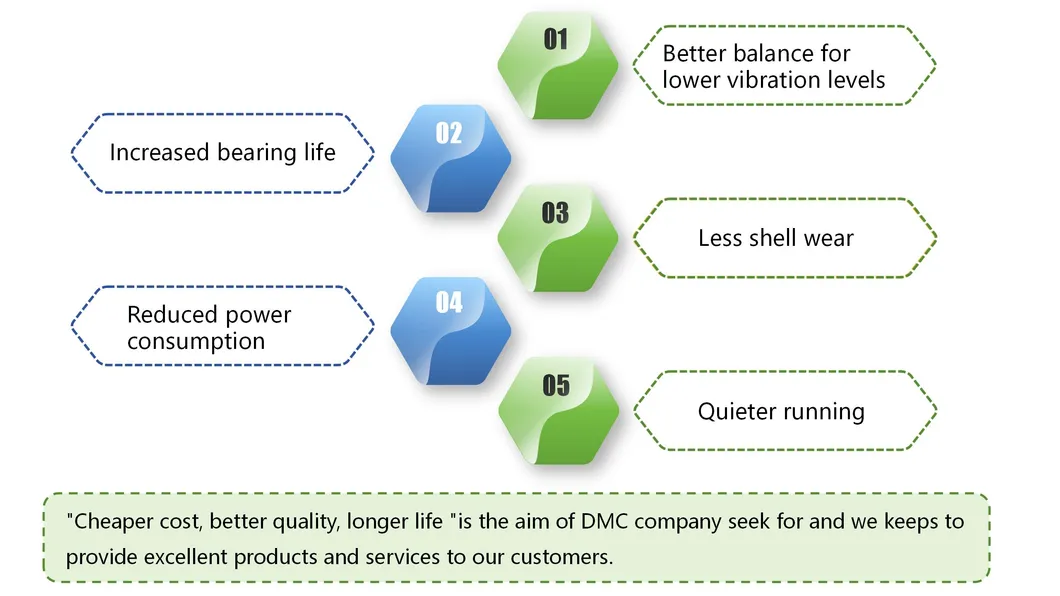

Dynamic Balancing

Our automatic manufacturing and assembling technique has succeeded in accurately balancing the unit to reduce all deviation,therefore both minimizing impact whilst the bearing works at high speed, consequently extending its life span.

Seal

Bearings of the roller are protected by internal and external sealing systems.These help to prevent the deterioration of the lubricating oil and protect the bearings from external dirt infiltration.

The sealing system fabrication incorporates:

* An anti corrosive,protecting shield firmly covering the roller to prevent the penetration from impurities.

* A rubber sealed cover which protects the lip line and prevents penetration by external liquids.

* A steel cover with shell as a guard to protect the bearing from external infiltration.

* A labyrinth seal with lubricating oil as the final stage of protection of the bearing even from dust molecules which may have by-passed the preceding levels of protection.

Examining and Testing

All rollers are subiect to extensive quality control testing and has gone through appropriate standards compliance.

Free from Maintenance

The labyrinth type of inner sealing is manufactured as a lubrication-free device avoiding the need for costly maintenance.

| Technical Parameters | ||||

| Standard Diameter | Length scope ( mm) | Bearings Type (Min~Max) |

Idler's Shell Wall Thickness | |

| mm | Inch | |||

| 63.5 | 2 1/2 | 150~3500 | 204 | 3.0mm~3.75mm |

| 76 | 3 | 150~3500 | 204 205 | 3.0mm~4.0mm |

| 89 | 3 1/3 | 150~3500 | 204 205 | 3.0mm~4.0mm |

| 102 | 4 | 150~3500 | 204 205 305 | 3.5mm~4.0mm |

| 108 | 4 1/4 | 150~3500 | 204 205 305 306 | 3.5mm~4.0mm |

| 114 | 4 1/2 | 150~3500 | 205 206 305 306 | 3.5mm~4.5mm |

| 127 | 5 | 150~3500 | 204 205 305 306 | 3.5mm~4.5mm |

| 133 | 5 1/4 | 150~3500 | 205 206 207 305 306 | 3.5mm~4.5mm |

| 140 | 5 1/2 | 150~3500 | 205 206 207 305 306 | 3.5mm~4.5mm |

| 152 | 6 | 150~3500 | 205 206 207 305 306 307 308 | 4.0mm~4.5mm |

| 159 | 6 1/4 | 150~3500 | 205 206 207 305 306 307 308 | 4.0mm~4.5mm |

| 165 | 6 1/2 | 150~3500 | 207 305 306 307 308 | 4.5mm~6.0mm |

| 177.8 | 7 | 150~3500 | 207 306 307 308 309 | 4.5mm~6.0mm |

| 190.7 | 7 1/2 | 150~3500 | 207 306 307 308 309 | 4.5mm~6.0mm |

| 194 | 7 5/8 | 150~3500 | 207 307 308 309 310 | 4.5mm~6.0mm |

| 219 | 8 5/8 | 150~3500 | 308 309 310 | 4.5mm~6.0mm |

Typical applicatios:

Mining---coal, iron ore,gold,Coal process plants,Coal fired power stations,Import/export terminals,Steel plants,Fertilizer plants,Cement plants,Gravel plants,Quarry.

${currentPro.title}