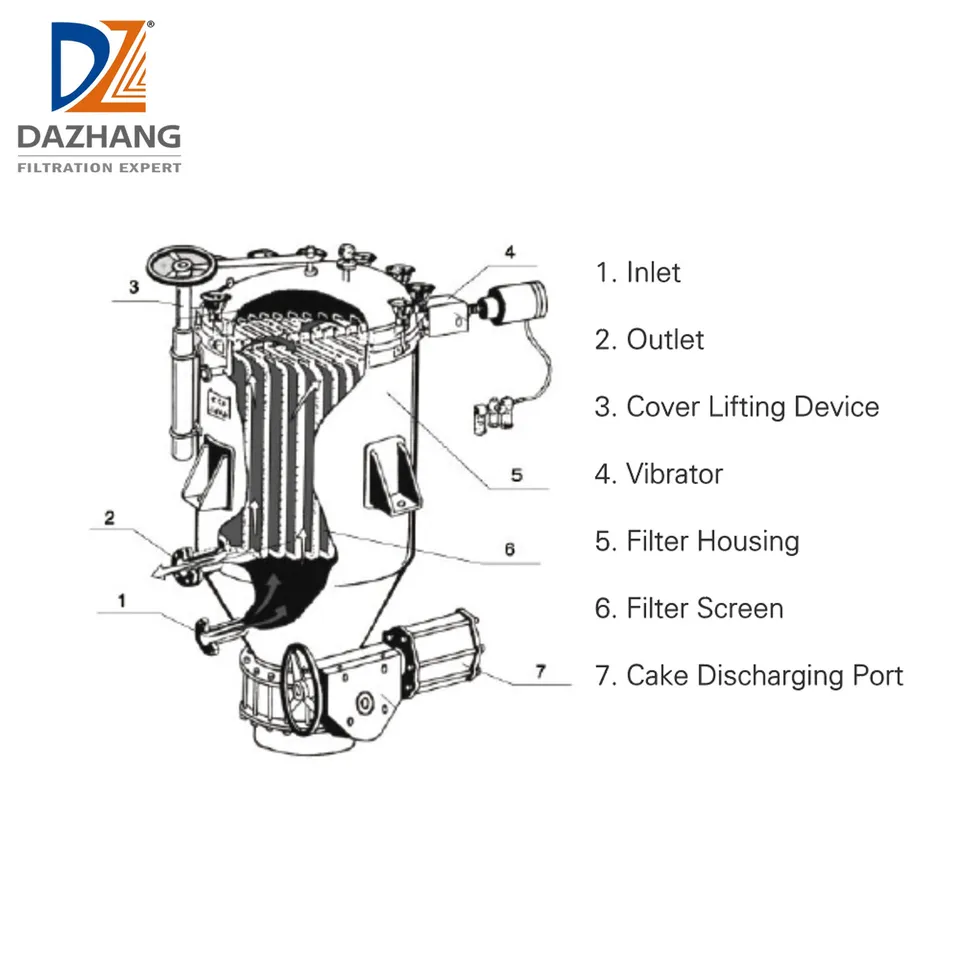

Vertical Leaf Filter with Auto Cake Discharging System

Description

Overview

Basic Info.

- Model NO. DZBL-45

- Work Pressure 0.1-0.4MPa

- Host Weight 1422kg

- Cylinder Diameter 1300*6mm

- Transport Package Woodcase

- Specification stainless steel

- Trademark DaZhang

- Origin Shanghai

Packaging & Delivery

- Package Size 250.00cm * 250.00cm * 350.00cm

- Package Gross Weight 1500.000kg

Product Description

Self-Cleaning Leaf Filter System – Low Maintenance, High Performance

DZBL high efficiency inclosed leaf filter belongs to stainless steel woven mesh filter. It is the new generation filtration equipment that we developed referencing foreign technology. The filter has unique and compacted design, and high filtering efficiency. It does not consume the filter cloth, filter paper or filter cartridge, just uses a little filter aid, so the filtration cost is low. And the machine is easy to operate, maintain and clean. Manual discharging and auto discharging are available according to customer's requirement. The filter area ranges from 2m² to 200m². The housing material can be carbon steel or stainless steel to meet clients' different needs.

The leaf filter consists of filter housing, filter screen, head lifting device and discharging device. According to the different filter materials it can customize various whole filtration system (Include the filter, mixing tank, feeding pump, pipes, valves, control system, etc.). The leaf is made of layers of stainless steel wire screens, then installed on the central filtrate collecting tube, so it's convenient to discharge and clean.

Shanghai Dazhang Environmental Protection Equipment Co., Ltd. is specialized in filtering solutions and projects. Dazhang (DZ) has over 20 years of experience in the filtration industry, especially in designing and manufacturing filtration equipment.

DZ Group covers an area of 570,000 square meters. DZ production base is equipped with advanced production lines and precise detection equipment. DZ has a high-quality assurance system to effectively monitor the whole process of warehousing, processing, and assembling. Sino-German joint venture production line can meet the needs of high-end filter press products.

DZ has a professional research and development team, experienced workers, and a high-quality sales team to provide clients excellent service, like testing, product selection, equipment installation and commissioning, user training, technical support, and after-sale service.

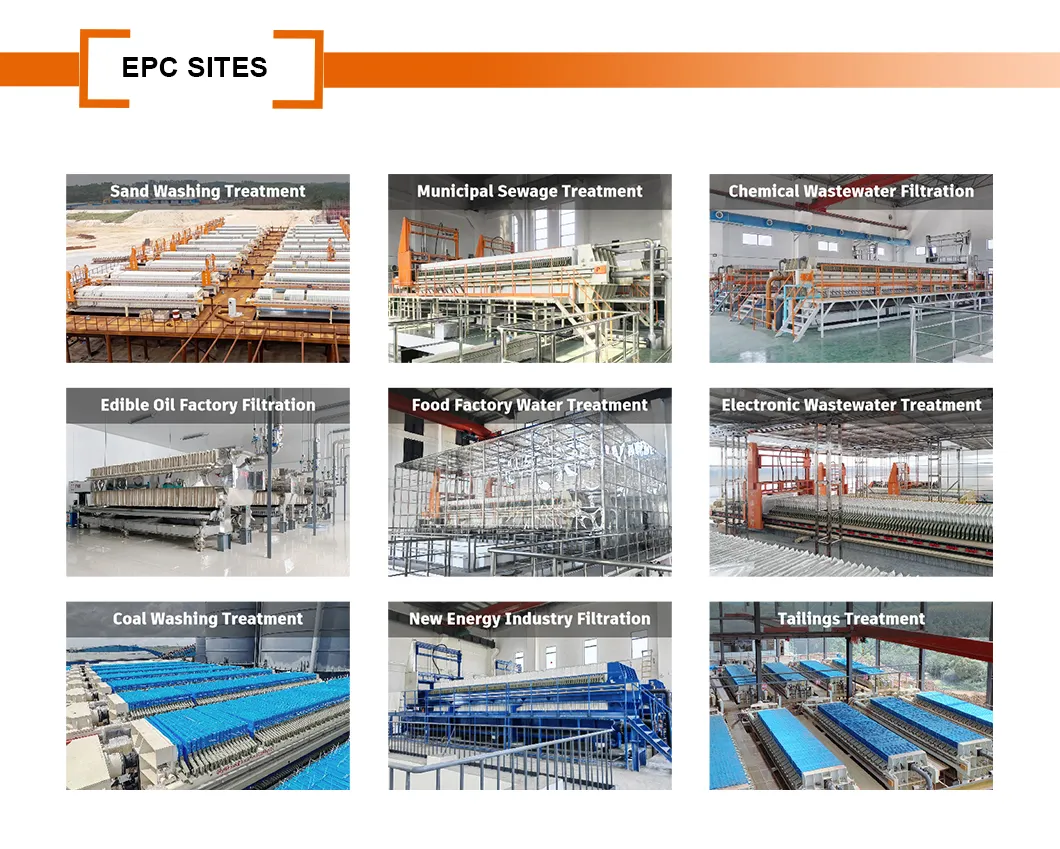

DZ provides diverse filtration equipment and corollary equipment, including bag filter, cartridge filter, membrane filter press, chamber filter press, belt filter press, dosing system and so on. DZ self-developed 1000 square meters filter press is famous for the domestic advanced technology in the filtration industry. DZ products are widely applicable to global chemical, metallurgy, petroleum, printing and dyeing, ceramics, food, pharmaceutical, building materials, coal mine, and wastewater treatment industries.

DZ was awarded the National Quality Credit Enterprise and the Excellent Science and Technology Enterprise in China. With high performance and high efficiency, DZ products sell well in more than 30 countries and regions. DZ is committed to providing users with comprehensive and complete filtration solutions.

Frequently Asked Questions

Q1. Are you a manufacturer or a trader?

We are an experienced manufacturer and has over 20 years industry experience.

Q2. How about the production capacity of your company?

Our factory covers area over 570,000m² and produces equipment more than 9500 sets per year.

Q3. How long is the delivery time?

Standard ready-made products can be delivered within 10 days. Also, we accept completely customized orders. The production time for customized products will be extended. We will have a dedicated team to serve each customer.

Q4. How long is the product warranty period?

The warranty period is one year, excluding the consumable parts and man-made damage.

Q5. What's the after sale service of your company?

We will provide installation video and online guidance. On-site service needs to be discussed based on the customer's requirements.

Q6. Can you provide long-term spare parts?

We can provide long-term replacement parts that can be replaced on the equipment.

${currentPro.title}