EN

Language

All categories

Product ID: 68589928

Top-Rated Conveyor Chain for Heavy-Duty Applications

Contact Now

Description

Basic Info.

Model NO.

FV140-P125

Chain Size

Customized

Structure

Conveyor Chain

Application

Automated Production Lines, Conveying System

Feature 1

High Tensile Strength

Feature 2

Heat Resistant

Feature 3

Corrosion and Weather Resistance

Feature 4

Low Maintenance

Feature 5

Customized

Transport Package

Carton Packing, Color Box, Wooden Case.

Specification

GB/T, DIN, ANSI, ISO, BS, JIS.

Trademark

BOSHI

Origin

Changzhou, Jiangsu

HS Code

7315119000

Production Capacity

80000m/Month

Packaging & Delivery

Package Size

20.00cm * 20.00cm * 20.00cm

Package Gross Weight

2.000kg

Product Description

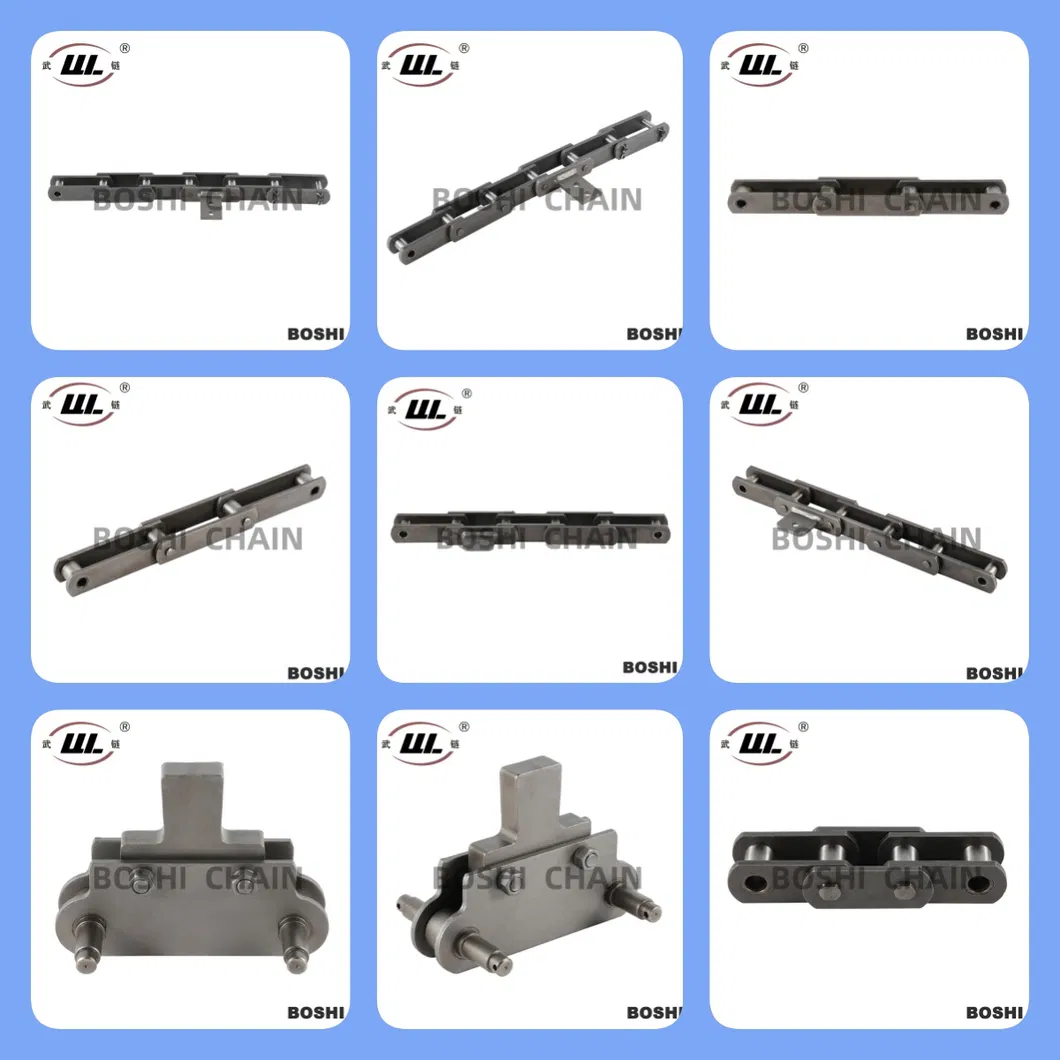

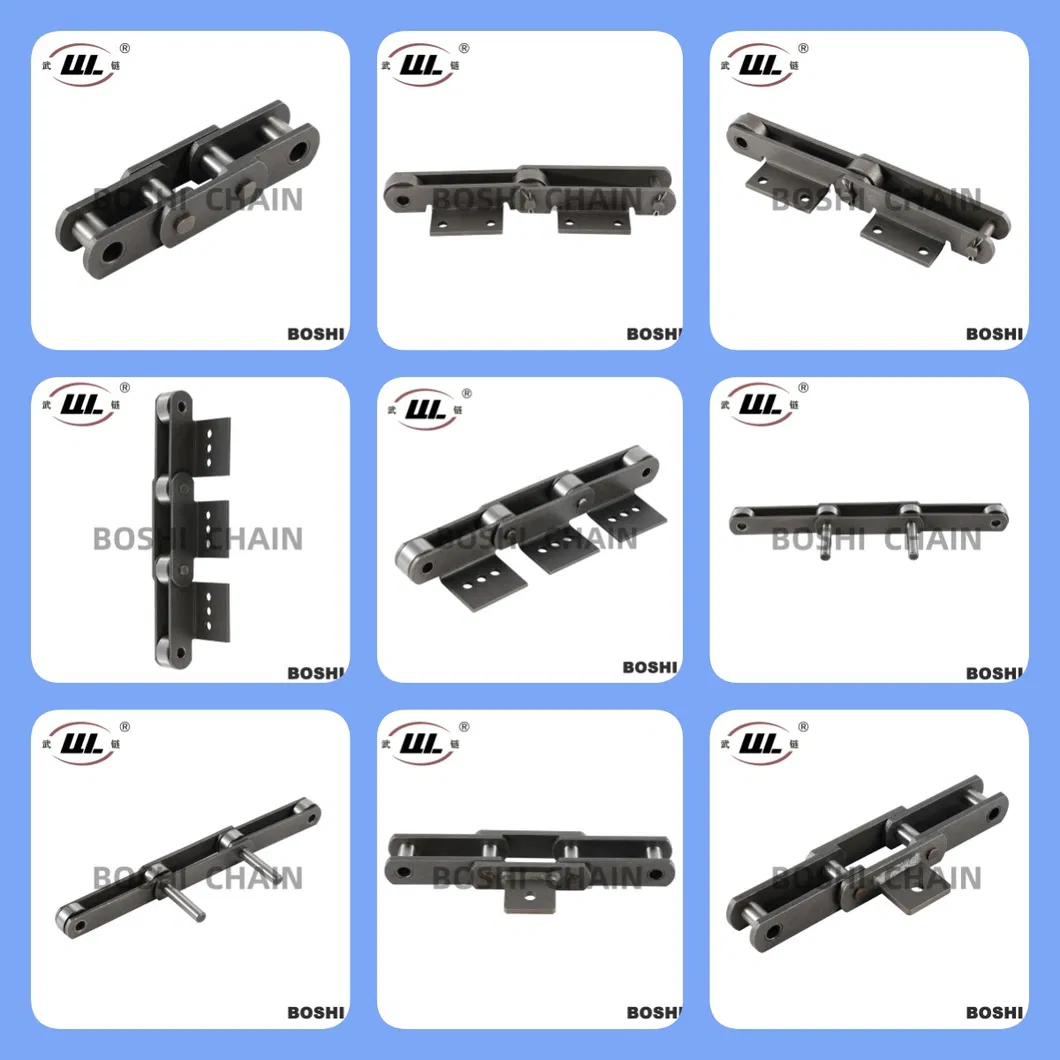

Conveyor Chain

The conveyor chain is a critical mechanical component used to transport materials and products in a variety of industries. It is typically composed of a series of interconnected chain links, with the structure and shape of the chain meticulously designed to meet specific operational requirements and withstand varying working conditions. The design of conveyor chains can vary significantly depending on factors such as the type of load, the environment in which they are used, and the speed and efficiency required. Due to their adaptability and versatility, conveyor chains have a broad range of applications, including use in automated production lines, logistics conveying systems, mining, metallurgy, building materials, and food processing industries.

Our factory can provide various specifications and models of chain customization services to meet customer needs.

Features of Conveyor Chain :

1. Customizable Design:

Conveyor chains are highly customizable to fit specific operational needs. The chain links can be tailored in terms of size, material, and design, ensuring optimal performance in different environments. Whether transporting heavy materials in a mining setting or handling delicate goods in food processing, conveyor chains can be adapted to handle various load capacities and wear conditions.

2. High Load Capacity:

Designed to handle heavy-duty operations, conveyor chains are capable of transporting large and heavy loads over long distances. This makes them particularly valuable in industries such as mining, construction, and metallurgy, where the movement of bulk materials is essential.

3. Durability and Strength:

Conveyor chains are typically manufactured from high-grade materials such as alloy steel, stainless steel, or other hardened metals. These materials offer excellent resistance to wear, corrosion, and extreme temperatures, making the chains suitable for use in harsh environments, such as underground mines or high-temperature industrial settings.

4. Low Maintenance:

Conveyor chains are designed to operate reliably for extended periods with minimal maintenance. Advanced lubrication systems and wear-resistant materials reduce the need for frequent repairs or replacements, enhancing operational efficiency and lowering maintenance costs.

5.Smooth and Continuous Operation:

The interconnected design of the chain links ensures smooth and continuous material flow. This is crucial in automated production lines and logistics systems, where any interruption in the conveyor process could result in costly downtime. Conveyor chains are engineered to provide consistent and reliable performance.

6. Adaptability to Various Environments:

Conveyor chains are designed to function in a wide range of environments, from high-humidity food processing plants to dusty construction sites. Special coatings and materials can be used to enhance resistance to environmental factors such as moisture, chemicals, or dust.

7. Energy Efficiency:

Conveyor chains are optimized for energy-efficient operation. Their design minimizes friction and mechanical resistance, reducing the amount of energy required to move materials. This is particularly important in industries where large volumes of material need to be moved continuously.

| TECHNICAL PARAMETERS | ||||||||||||||||

| Chain No. | Pitch | Roller dimension | Inside Width |

Height of plate |

Pin dia | Length of Pin | Ultimate tensile strength |

|||||||||

| P | d1( max) | d3( max) | b2( max) | d4( max) | b1( min) | h2( max) | d2( max) | L( max) | Q | |||||||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | KN | |||||||

| M20 | 50 | 63 | 80 | 100 | 125 | 160 | 25 | 35 | 3.5 | 12.5 | 15 | 19 | 6.0 | 35 | 20 | |

| M28 | 63 | 80 | 100 | 125 | 160 | 200 | 30 | 40 | 4.0 | 15.0 | 17 | 21 | 7.0 | 40 | 28 | |

| M40 | 80 | 100 | 125 | 160 | 200 | 250 | 36 | 45 | 4.5 | 18.0 | 19 | 26 | 8.5 | 45 | 40 | |

| M56 | 80 | 100 | 125 | 160 | 200 | 250 | 42 | 55 | 5.0 | 21.0 | 23 | 31 | 10.0 | 52 | 56 | |

| M80 | 100 | 125 | 160 | 200 | 250 | 315 | 50 | 65 | 6.0 | 25.0 | 27 | 36 | 12.0 | 62 | 80 | |

| M112 | 125 | 160 | 200 | 250 | 315 | 400 | 60 | 75 | 7.0 | 30.0 | 31 | 41 | 15.0 | 73 | 112 | |

| M160 | 160 | 200 | 250 | 315 | 400 | 500 | 70 | 90 | 8.5 | 36.0 | 36 | 51 | 18.0 | 85 | 160 | |

| M224 | 200 | 250 | 315 | 400 | 500 | 630 | 85 | 105 | 10.0 | 42.0 | 42 | 62 | 21.0 | 98 | 224 | |

| M315 | 200 | 250 | 315 | 400 | 500 | 630 | 100 | 125 | 12.0 | 50.0 | 47 | 72 | 25.0 | 112 | 315 | |

| M450 | 250 | 315 | 400 | 500 | 630 | 800 | 120 | 150 | 14.0 | 60.0 | 55 | 82 | 30.0 | 135 | 450 | |

| M630 | 250 | 315 | 400 | 500 | 630 | 800 | 140 | 175 | 16.0 | 70.0 | 65 | 105 | 36.0 | 154 | 630 | |

| M900 | 315 | 400 | 500 | 630 | 800 | 1000 | 170 | 210 | 18.0 | 85.0 | 76 | 123 | 44.0 | 180 | 900 | |

| 2915-10 | 76.2 | 38.4 | _ | _ | _ | 24.4 | 28.7 | 11.20 | 58.9 | 48.95 | ||||||

| 2915-20 | 101.6 | 38 | _ | _ | _ | 24.2 | 28.7 | 11.20 | 58.9 | 48.95 | ||||||

| 2915-30 | 101.6 | 51.1 | _ | _ | _ | 27.7 | 31.8 | 11.20 | 63.8 | 62.30 | ||||||

| 2915-40 | 101.6 | 38.4 | _ | _ | _ | 21.1 | 31.8 | 12.78 | 64.3 | 71.20 | ||||||

| 2915-50 | 101.6 | 57.4 | _ | _ | _ | 32.0 | 31.8 | 15.95 | 90.9 | 106.80 | ||||||

| 2915-60 | 152.4 | 51.1 | _ | _ | _ | 27.4 | 31.8 | 11.20 | 69.1 | 66.75 | ||||||

| 2915-70 | 152.4 | 63.8 | _ | _ | _ | 30.5 | 38.1 | 14.38 | 76.7 | 89.00 | ||||||

| 2915-80 | 152.4 | 51.1 | _ | _ | _ | 32.0 | 38.1 | 15.95 | 87.6 | 102.35 | ||||||

| 2915-90 | 152.4 | 76.5 | _ | _ | _ | 33.83 | 50.8 | 19.13 | 97.8 | 146.85 | ||||||

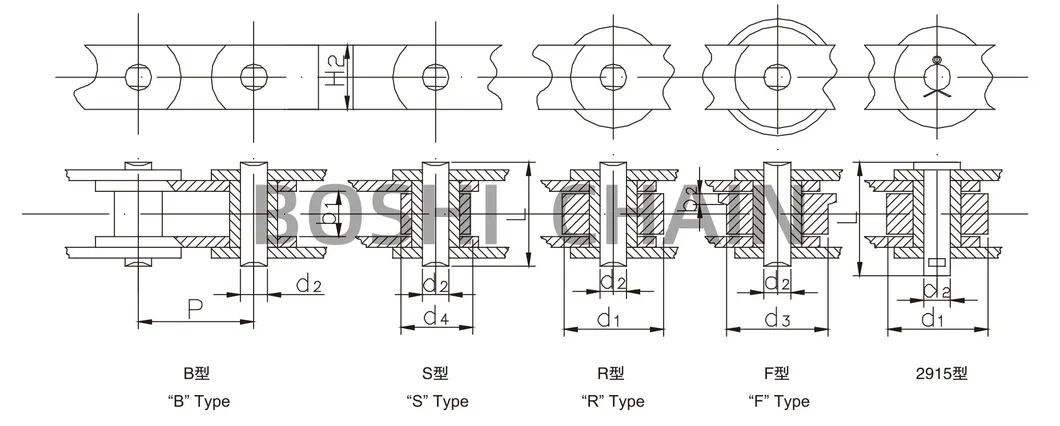

Drawing

Applications of Conveyor Chains

1. Automated Production Lines:Conveyor chains are extensively used in manufacturing industries for the efficient and continuous movement of products between different stages of the production process. From automotive assembly lines to electronic goods production, conveyor chains ensure smooth product flow, enhancing overall productivity.

2. Logistics and Material Handling:

In logistics and warehouse operations, conveyor chains are essential for moving packages and goods along sorting and distribution lines. They are also used in automated storage and retrieval systems (ASRS) to optimize the movement and organization of inventory.

3. Mining and Metallurgy:

Conveyor chains play a crucial role in the mining and metallurgy industries, where they are used to transport raw materials such as coal, ore, and metals. They are engineered to withstand abrasive materials, high temperatures, and other harsh conditions common in these environments.

4. Building Materials Industry:

Conveyor chains are used in the production and transportation of building materials such as cement, bricks, and aggregates. They provide the strength and reliability needed to move heavy and bulky materials efficiently in construction settings.

5. Food Processing:

In the food processing industry, conveyor chains are used for transporting ingredients, packaged goods, and processed foods. They are designed to meet strict hygiene standards, using materials that are easy to clean and resistant to corrosion, ensuring safe and efficient food handling.

Metallurgy

Contact Now

Please Send Message

${currentPro.title}