Stainless Steel 304/316 Metal Eye Link Conveyor Belts with Sprocket

Description

Overview

Basic Info.

Model NO. JM-2583

Inside Material Stainless Steel

Feature Oil-Resistant, Acid And Alkali Resistant, Tear-Resistant, Heat-Resistant, Cold-Resistant, Wear-Resistant

Tensile Strength Strong

Samples Free

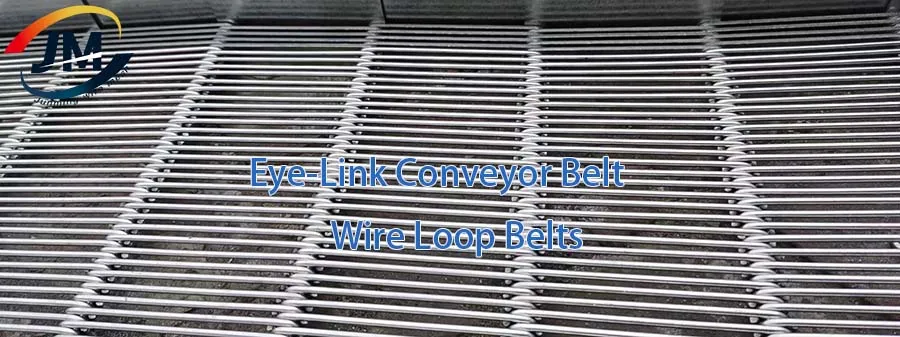

Product Name Eye Link Conveyor Belt

Spiral Pitch 5mm, 10mm, 15mm or Customized

Rod Daimeter 3-12mm

OEM Valid

Business Type Factory & Manufacturer

Product Grade Food Grade

Keyword Eye Link Conveyor Belt

Raw Material 304 316 316L 430 310 Stainless Steel Wire, Galvani

Chain/Pin Pitch 25.4mm/31.75mm/38.1mm/50.8mm/63.5mm/76.2mm

Heat Resistant -55-1150ºC

Features Easy to Clean, Driven by Sprockets or Roller Drum

Transport Package Wooden Cases

Specification Customized

Trademark JM

Origin Made in China

HS Code 84389000

Production Capacity 300square Meter/Day

Packaging & Delivery

Package Size 55.00cm * 55.00cm * 40.00cm

Package Gross Weight 200.000kg

Product Description

Stainless Steel 304 316 Metal Eye Link Conveyor Belts with SprocketBelt, Conveyor Belting, Conveyor Belt, Heat Resistant Conveyor Belt, Conveyor, V Belt, Belt Conveyor, Conveyor Chain, Transmission Belt, Industrial Belt, Stainless Steel Conveyor Belt, Mesh Belt, Wire Mesh Conveyor Belt, Mesh Belt, Food Conveyor Belt, Spiral Conveyor Belt

Technical Specifications

| Units | |

|---|---|

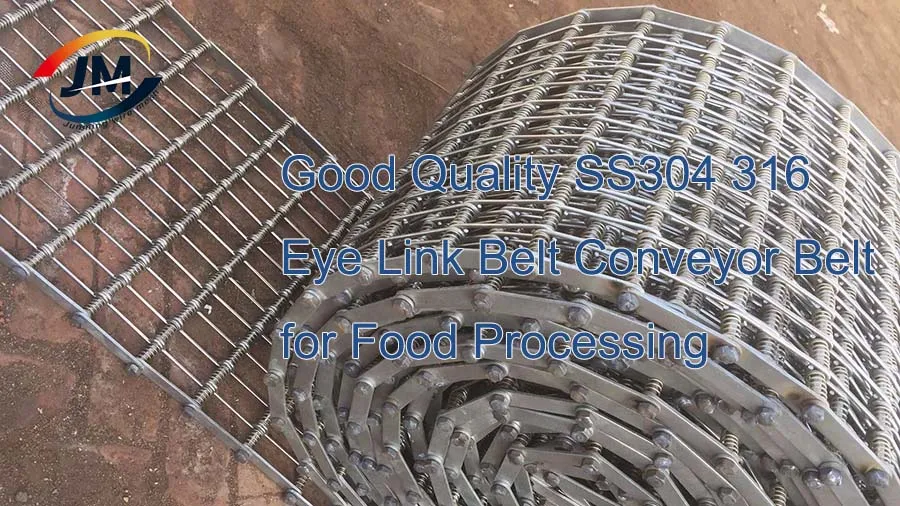

| Available Materials | 304, 316 stainless steel, carbon, other materials available upon request |

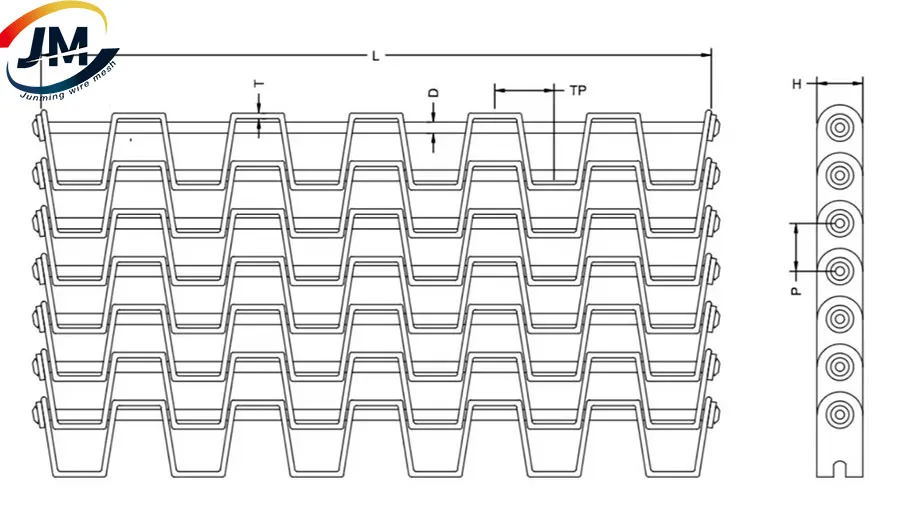

| Longitudinal Pitch Lengths | In. (mm) 1.00(25.4), 1.18(30.0), 1.97(50.0), 2.00(50.8), 2.95(75.0) |

| Eye Link Wire Diameters | In. (mm) 0.08(2.0), 0.10(2.5), 0.12(3.0), 0.14(3.5) |

| Cross Rod Diameters | In. (mm) 0.16(4.0), 0.20(5.0), 0.28(7.0), 0.32(8.0) |

| Available Widths | In. (mm) 2.0-244.0(50.8-6197.6) |

| Conveying Surface | In. (mm) Full belt width minus 0.32(8.1) |

| Weight | Dependent upon construction |

| Maximum Allowable Tension | Dependent upon construction |

| Maximum Temperature | (ºC) Up to 752(400) |

| Method of Drive | Positively driven |

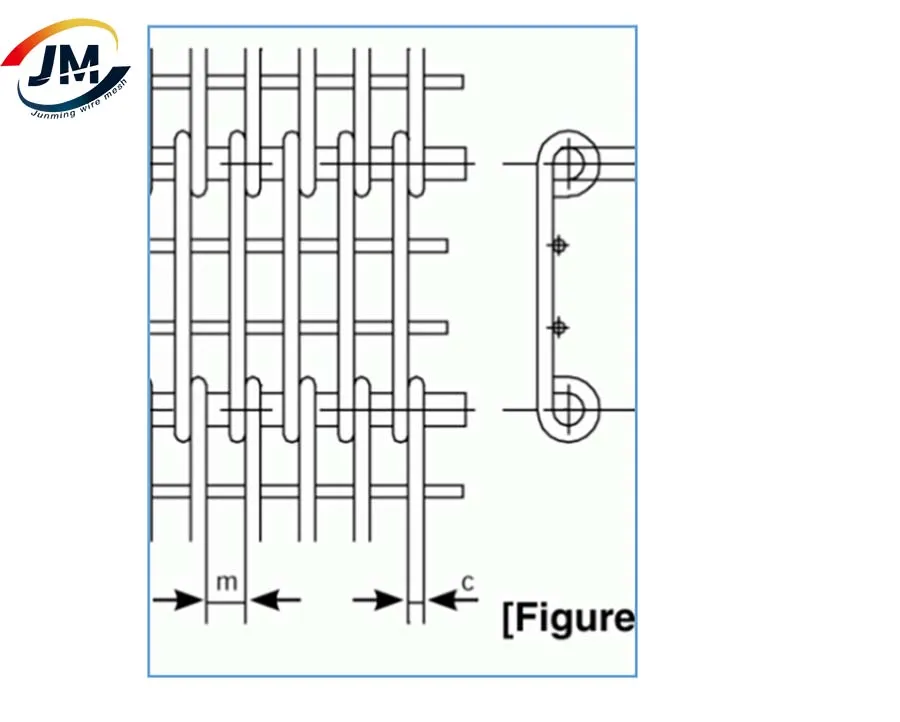

Mesh Designations

Mesh configurations for Eye-Link belts are designated as in the following example A X M/C-D 50 X 10/2.5-5 Where: 50 = belt's longitudinal pitch in mm 10 = distance between eye link in mm 2.5 = Eye link wire diameter in mm 5 = Cross rod diameter in mm Loose Chain & Chain Edges All Eye-Link belts can be fitted with either loose chain made from bar links or with chain edges to suit customer specifications.

Eye Link Belt Features:

Made by round mesh wire shaped glass then string up by cross rods, light weight, easy to clean, driven by sprockets or roller drum. Running smoothly, easy to maintaining. Range of applied: Usually used for following applications: freezing, foundry equipment, quench tanks, dehydration equipment, sterilization equipment, drying equipment, steel blast equipment, filtering equipment, packing equipment, baking stove, cooling equipment, blanching equipment, storage equipment, shrinkable packaging device washing machines etc.

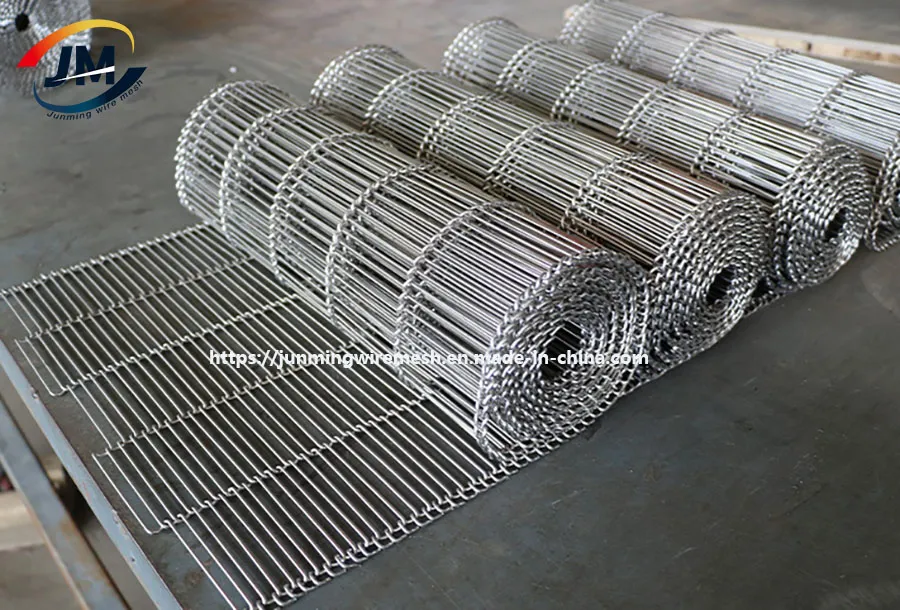

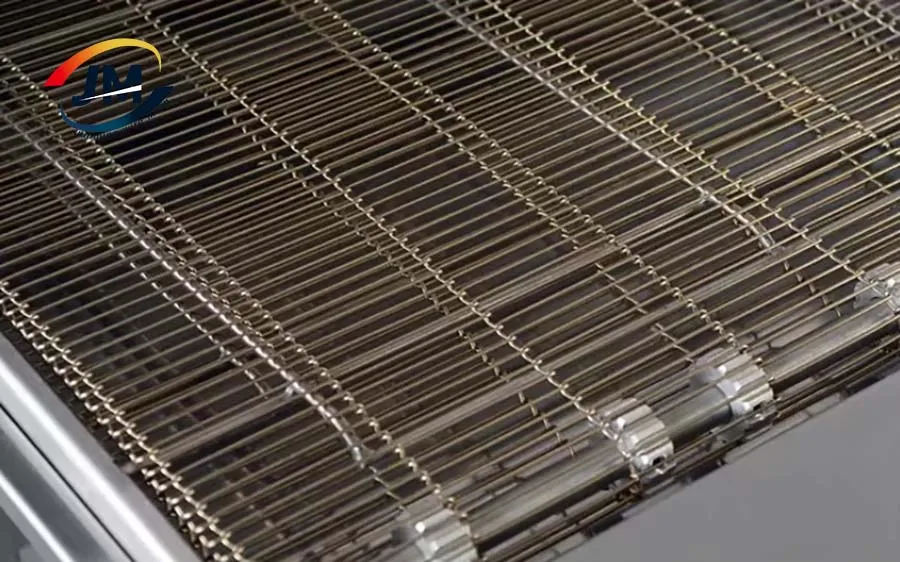

Type2: Flat Flex Conveyor Belts

Flat flex conveyor belts also known as rod network conveyor belts, or enrober conveyor belts, are distinguished by their unique construction and versatile applications, these belts are constructed from a series of looped wires that interlock with one another, creating a flexible and robust mesh, the simple structure makes it economical and lightweight. It can help to save costs and reduce downtime.

Stainless Steel Wire Mesh Conveyor Belt, Pizza Oven Chocolate Enrober Flat Flex Belt Conveyor

Materials Stainless Steel Wire 304, 304l, 316, 316L, 310s, etc

Wire Diameter 1mm, 1.2mm, 1.5mm, 1.6mm, 1.8mm, 2.0mm, 2.5mm, 2.8mm, Customized

Chain Pitch 5mm, 6mm, 7mm, 10mm. Customized

Space Number Usual Singular, we need to know the number

Width 1.5M-5.5M, customized

Operating Temperature -40ºC-1200ºC

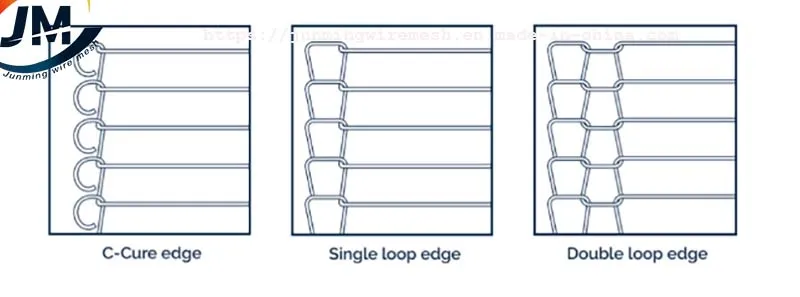

Edge Treatment Single Loop Edge, Double Loop Edge and C Shape Edge

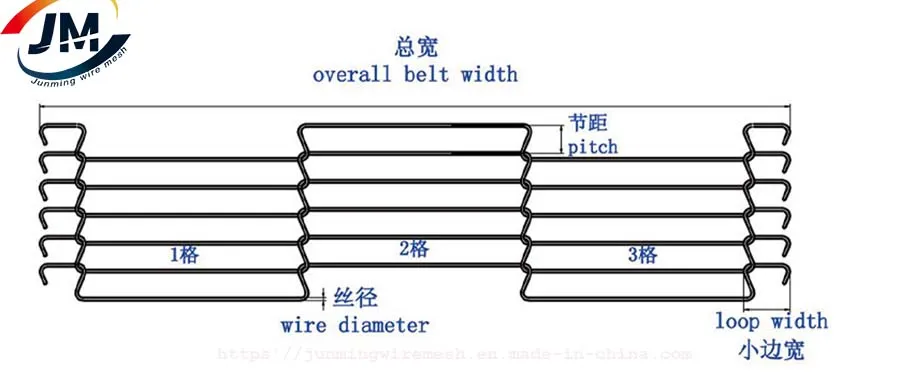

How To Identify A Flat Flex Conveyor Belt?

Every Conveyor belt must be properly identified before replacement. Use the following guide to identify a flat flex conveyor belt.Flat flex wire mesh belts are the lightest weight, open area, economical, and thinnest positive drive wire conveyor belt in the industry.

- Determine belt width. Measure the overall belt width to the nearest 1/16", from outside edge to outside edge.

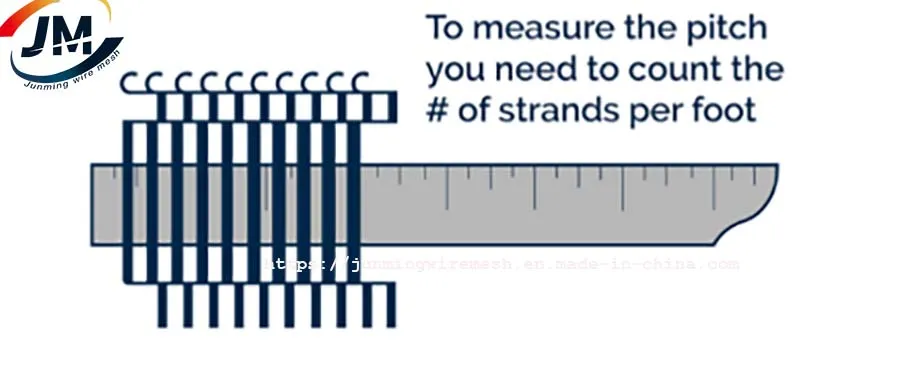

- Determine mesh size. The mesh size equals the strands per foot(SPF) multiplied by the wire diameter(SPF x wire diameter = mesh size).Measure the wire diameter using vernier calipers, a micrometer, or a wire gauge.Count the number of strands per foot(SPF)by pulling the slack out of the belt and count the strands in 12", do not count the first strand.

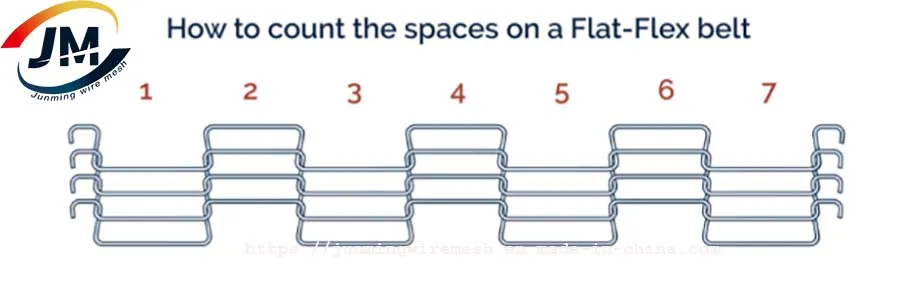

- Determine spaces. Count the number of rectangular openings(or spaces)across the width of the belt.

- Determine edge style. Check to see if you are using a C-Cure Edge, single loop edge, or double loop edge.

Flat Flex Belt Materials:

302, 304, 316L Stainless Steel, Carbon Steels, Specialized materials suitable for high-temperatures

Flat Flex Edge Loop Options:

C-Cure Edge, single loop edge, or double loop edge.

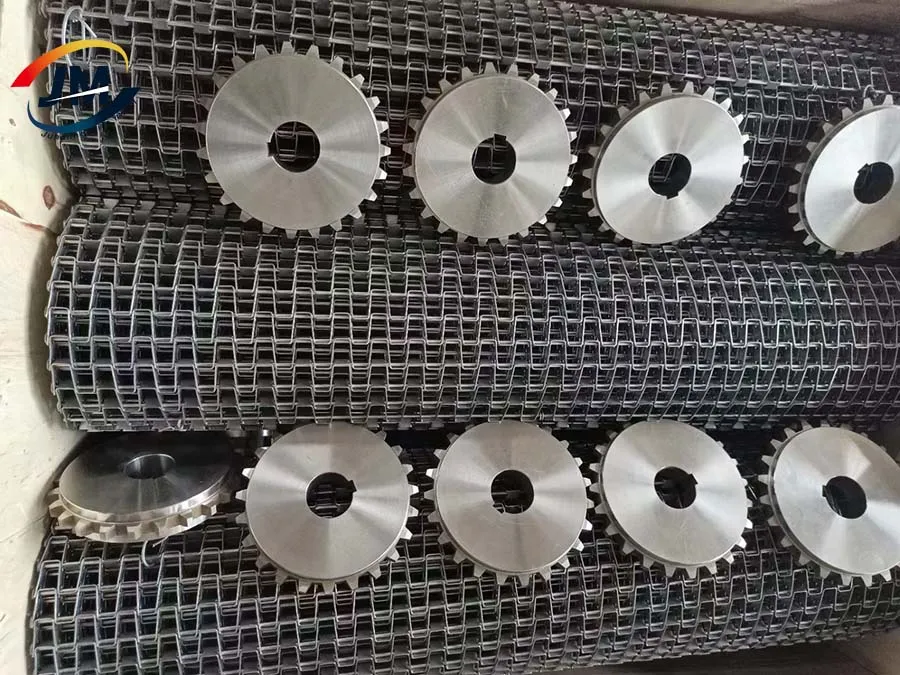

Fitting Parts:

Chains, Sprockets

Type 3: Balanced Spiral Belt/Chain Link Conveyor Belt

Balanced Spiral Belt/Chain Link Conveyor Belt is an extremely popular mesh design, found in almost every manufacturing industry with a wide ranging number of possible applications.Balanced Spiral Belt/Chain Link Conveyor Belt is made of the chain and the transverse support rod on both sides of the general conveyor belt, the sprocket is driven, and the net belt is fixed with wide band without deformation.

Benefits of Balanced Spiral belt include straight-running operation, an excellent strength to weight ratio and an extremely wide variety of mesh specifications to suit each individual application.

It can be the delivery of granular materials, can also be carried into the delivery of items. Suitable for high density transportation in small. Smooth motion, strong. Convenient installation and replacement, high cost, long service life.

Product Name

Chain link conveyor belt, Spiral Conveyor belt, Spiral grid link conveyor belts, Flat spiral conveyor belt, Cam grid conveyor belt, Balanced spiral belt, Spiral food conveyor belt, Chain conveyor belt mesh

Material 304 316 316L 430 310 Stainless steel wire, Galvanized steel wire, Black iron wire

Spiral wire diameter(D) 1.2mm-3.0mm Customized is workable

Spiral pitch(A) 2.4mm-100mm, Spiral wire center to wire center

Rod wire diameter(C) Same as spiral wire, or bigger than spiral wire

Rod wire pitch(B) We can do it as customer's requirement

Support rod diameter 5-12mm, According to customer's requirement

Chain/pin pitch 25.4mm/31.75mm/38.1mm/50.8mm/63.5mm/76.2mm, we can do it as customer's requirement.

Support rod distance As customer's requirement

Overall width 100-6000mm, Include chain width, or not include chain width, please kindly note it

Length As customer's requirement

Spiral conveyor belt is usually used in quick-frozen food industry, It is one of the indispensable accessories of quick-frozen machine. It is different from ordinary woven metal mesh belt. This kind of mesh belt is composed of thick stainless steel straight bar, U-shaped chain and stainless steel caps.

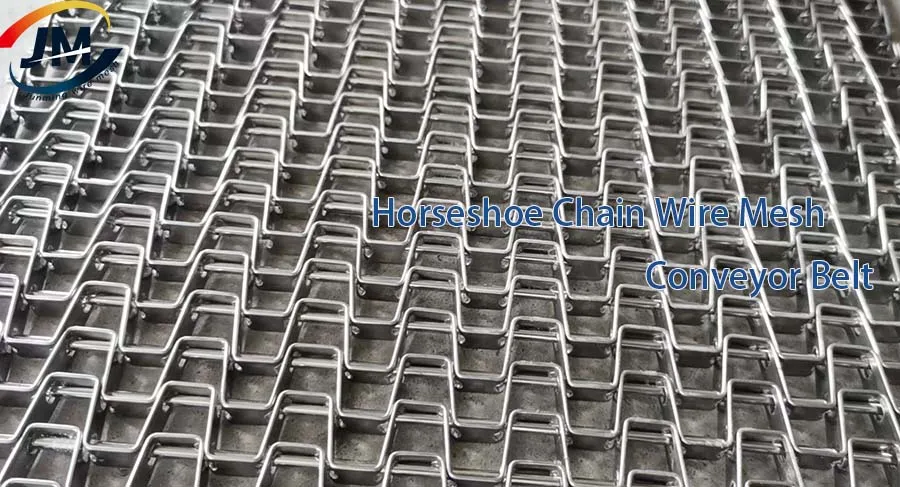

Type 4: Horseshoe Chain Wire Mesh Conveyor Belt

Stainless steel metal honeycomb mesh conveyor belts is widely used in glass industry, food processing industry.Wire mesh conveyor belt is widely used in areas such as cement, metallurgy, casing, chemical transport materials.Wire mesh conveyor belt can be used for high temperature resistant, resistant to burn conveyor belt, electronic balance tear conveyor belt etcInstant noodles and rice industry.

Packaging & Shipping

${currentPro.title}