9-Mohs Hardness Alumina Ceramic Tile for Ball Mill Linings

Description

Overview

Basic Info.

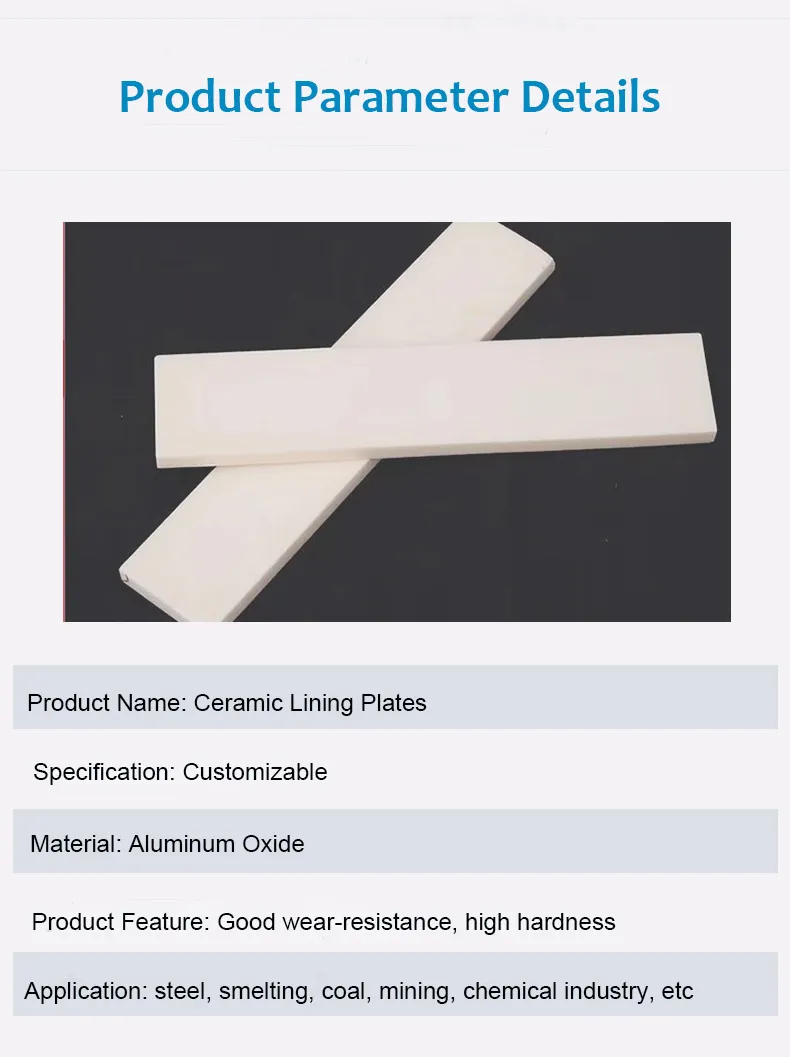

Model NO.: zczgb01

Material: Aluminum

Type: Wear Resistant Ceramic

Al2O3: 92%

Density: 3.83 G/Cm³

Hv 20: 1200

Rock Hardness Hra: 90

Bending Strength MPa: 330

Compression Strength MPa: 1800

Fracture Toughness Kic Mpam 1/2: 4.2

Transport Package: Carton Box + Pallet

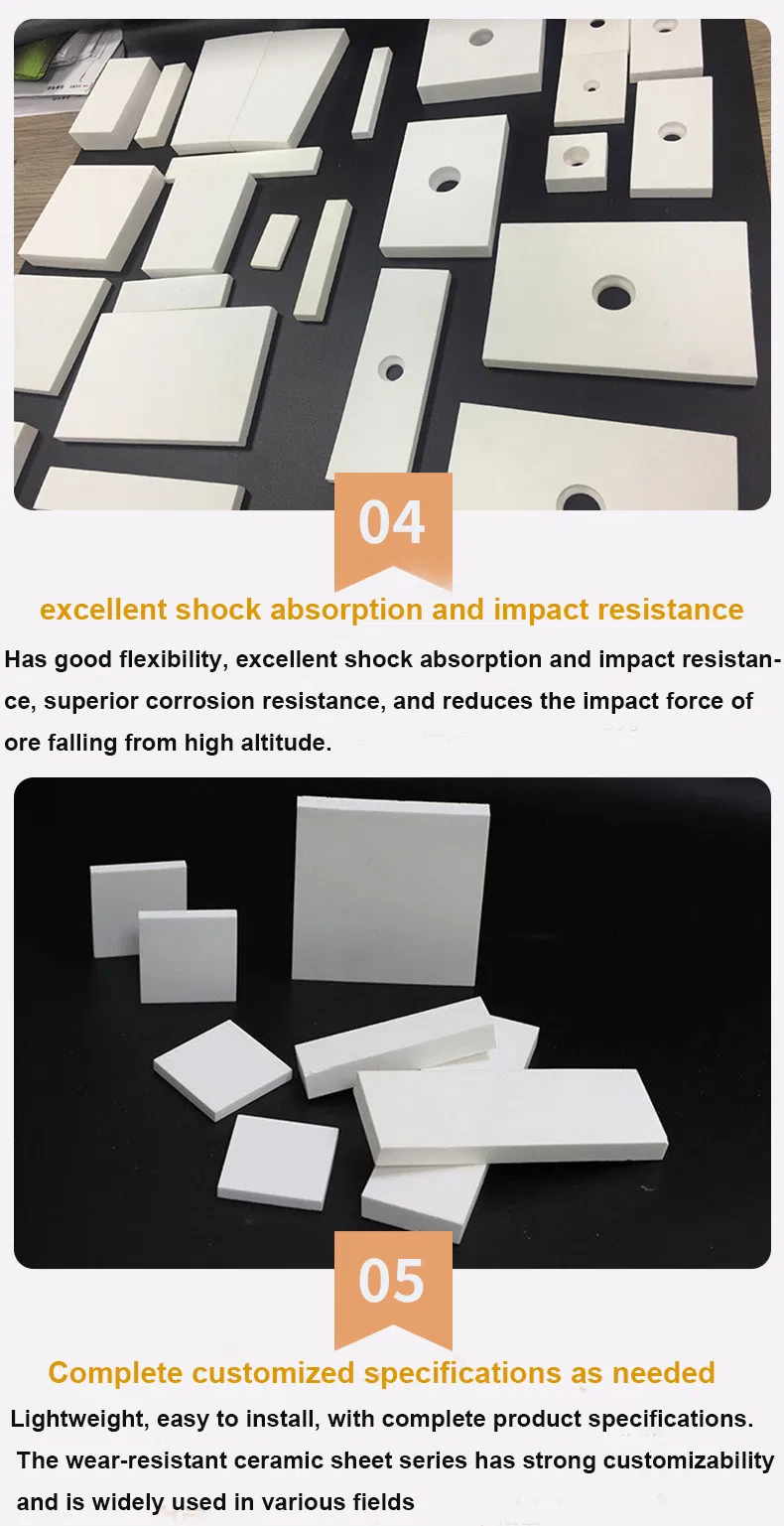

Specification: 100X100X6~50mm, 150X100X6~50mm, etc.

Trademark: Zhongci

Origin: China

HS Code: 69091200

Production Capacity: 10000 ton/Year

Product Description

Mohs Hardness 9 Super Wear Resistant Alumina Ceramic Tile Ball Mill Linings

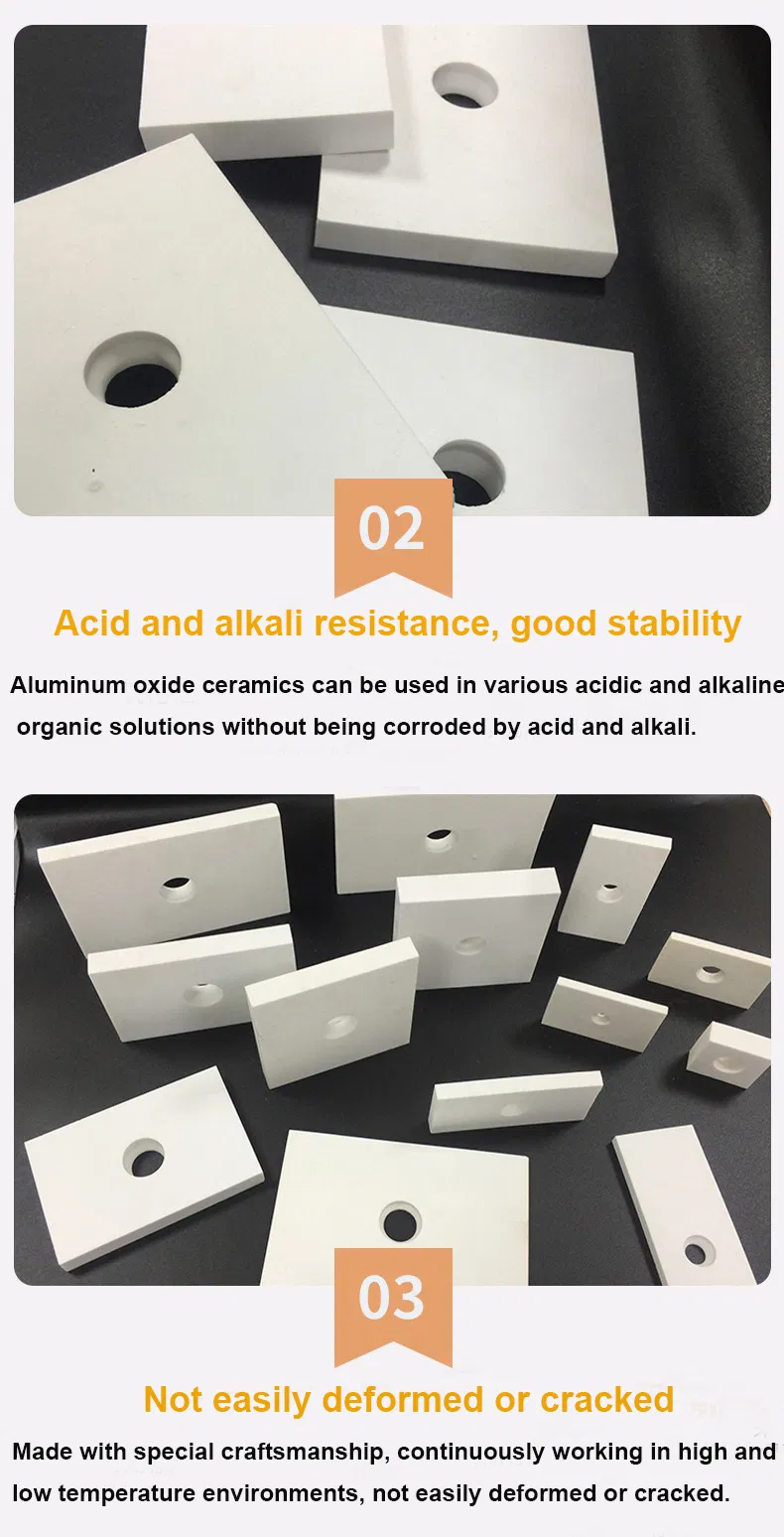

Ceramic is a material with beneficial anti-impact properties that prolong wear life and improve impact resistance. Ceramic wear liners are designed to be extremely resistant to abrasion even in high material flows and speeds, preventing material build-up. Used in heavy industry for years as a cost-effective, wear-resistant solution, these lightweight materials offer high durability, strength, and excellent abrasion and corrosion resistance.

Alumina wear resistant compositions include:

- Alumina 92: most common wear product with great wear resistance

- Alumina 95: increased wear performance

- Alumina T95: premium alumina for best wear resistance

- Zirconium toughened alumina (ZTA): increased strength and impact resistance

Alumina mill linings (alumina bricks and tiles) are the perfect solution for protecting grinding ball mills from wear, as they allow for a constant use over an extended period of time without any routine maintenance.

Feature:

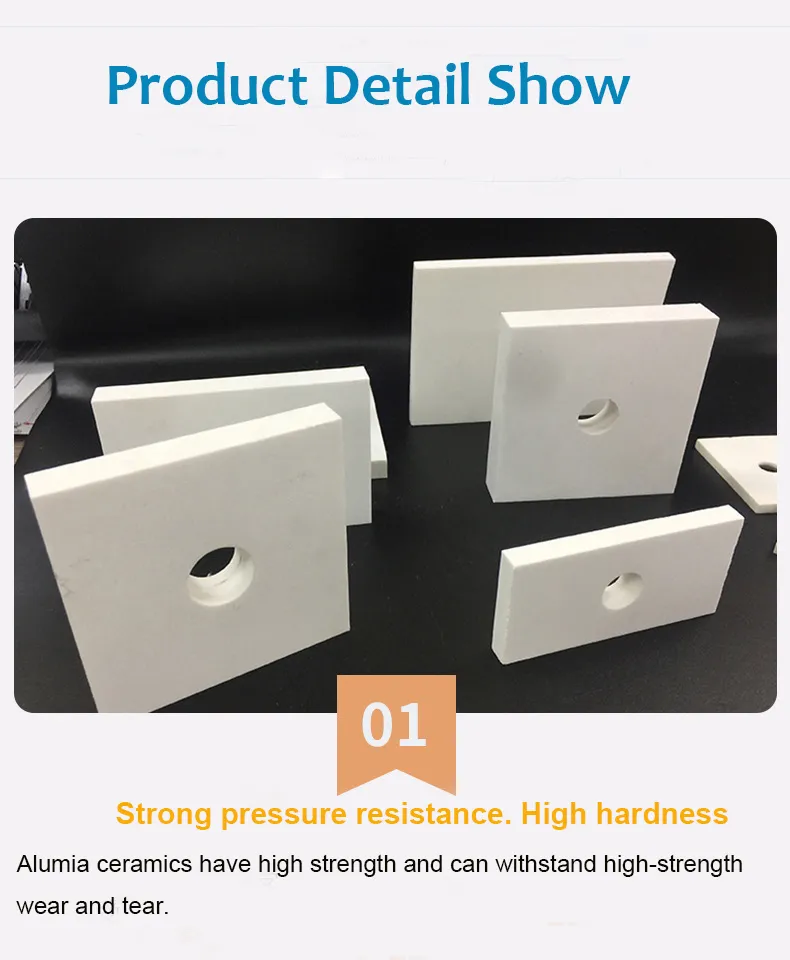

High performance abrasion resistance lining brick is one of our main products by the advanced technology with the perfect character in abrasion resistance, external appearance, complete specification, and easier application.

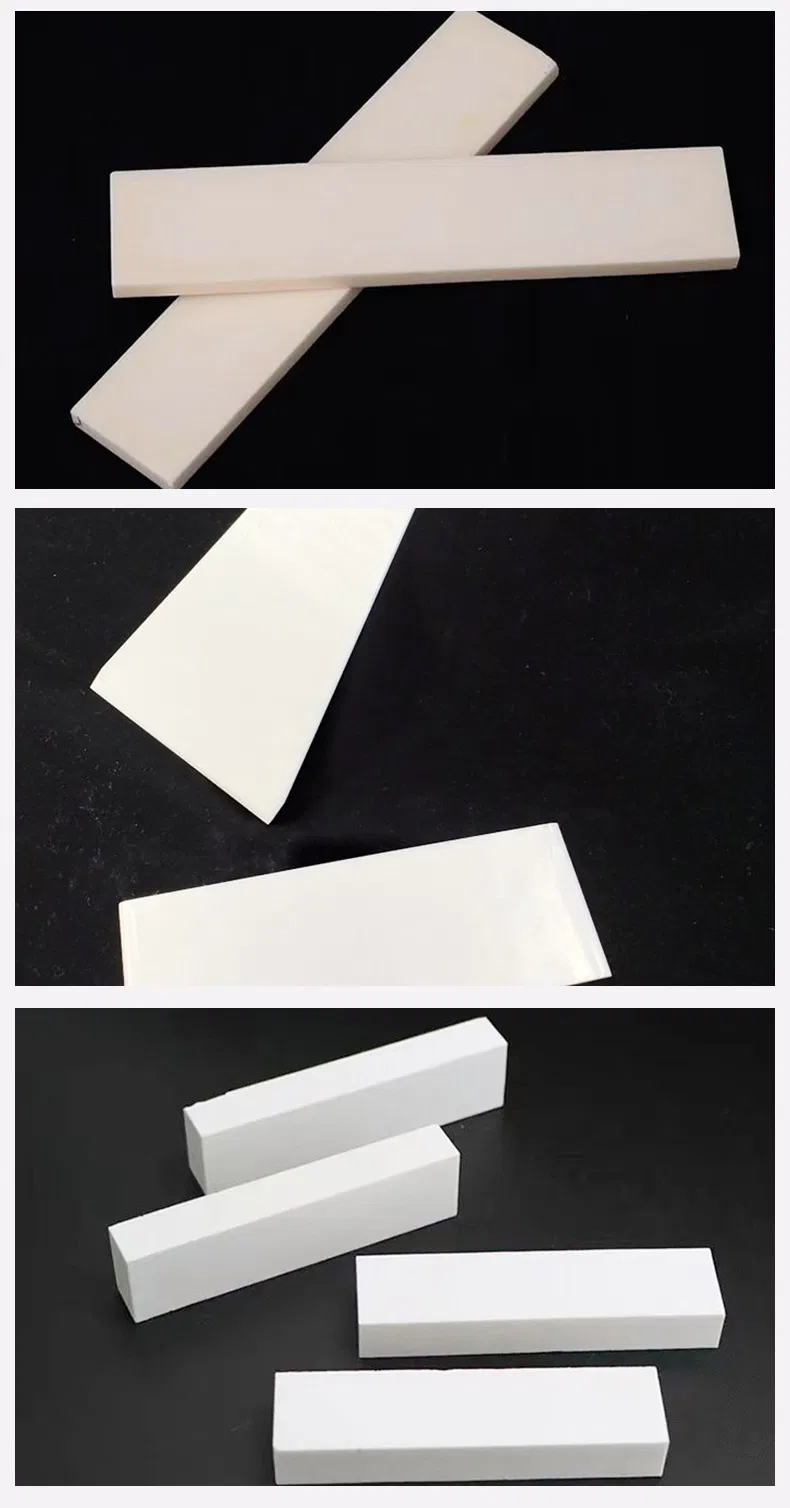

Rectangle brick

| L(mm) | 150 | 150 | 150 | 150 | 150 |

|---|---|---|---|---|---|

| W(mm) | 50 | 50 | 50 | 50 | 50 |

| H(mm) | 40 | 50 | 60 | 70 | 100 |

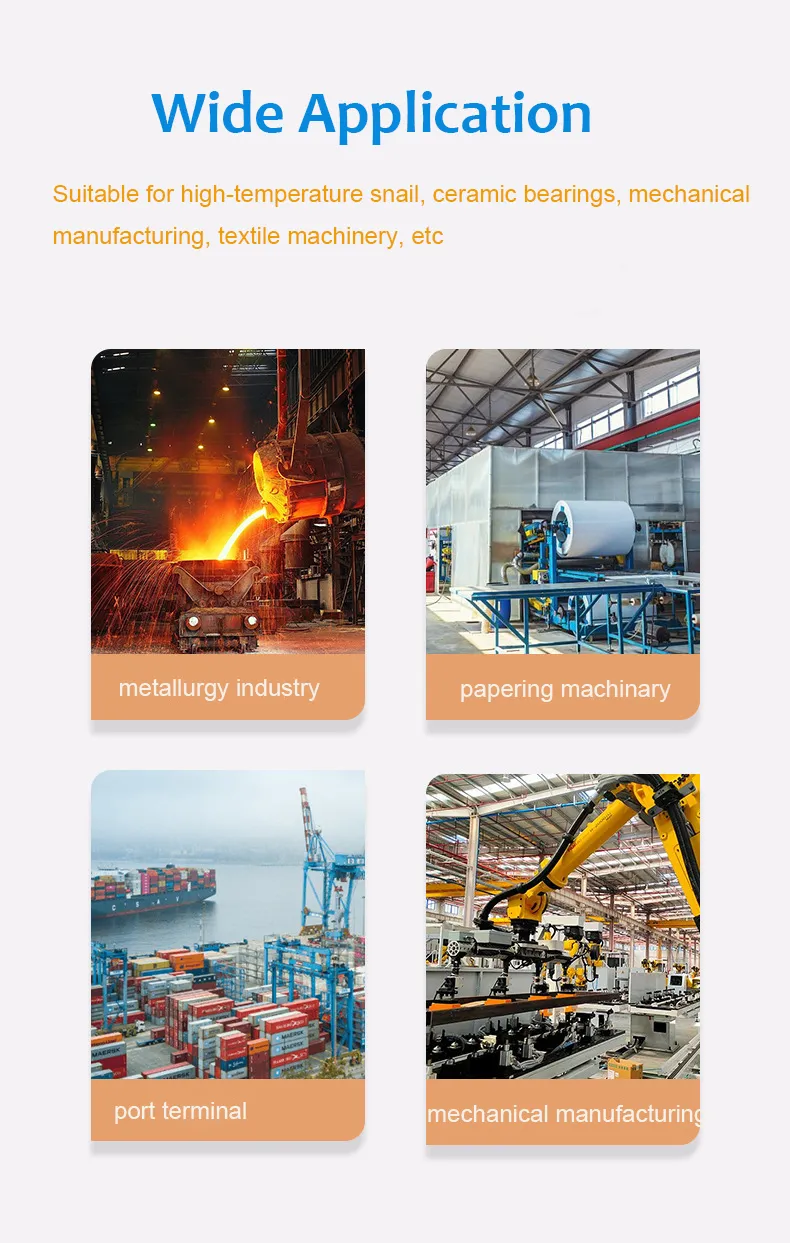

Application

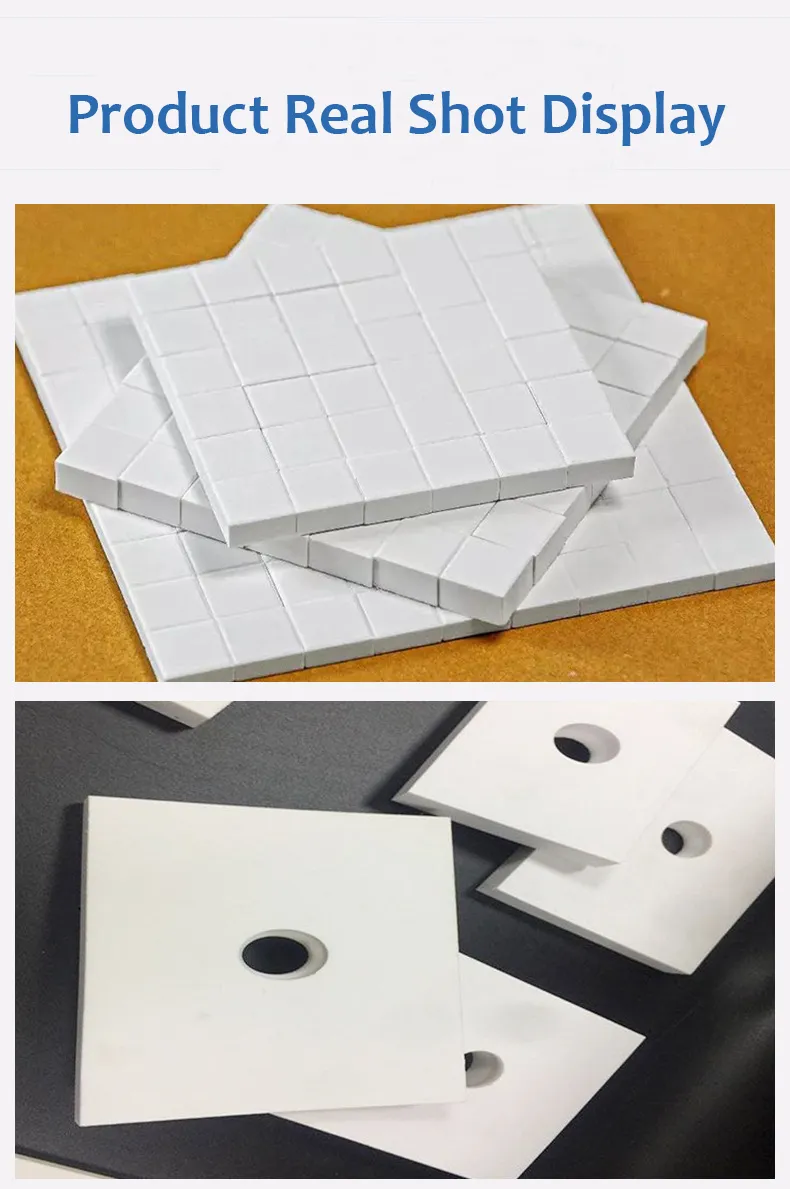

Detailed Photos

Production Flow

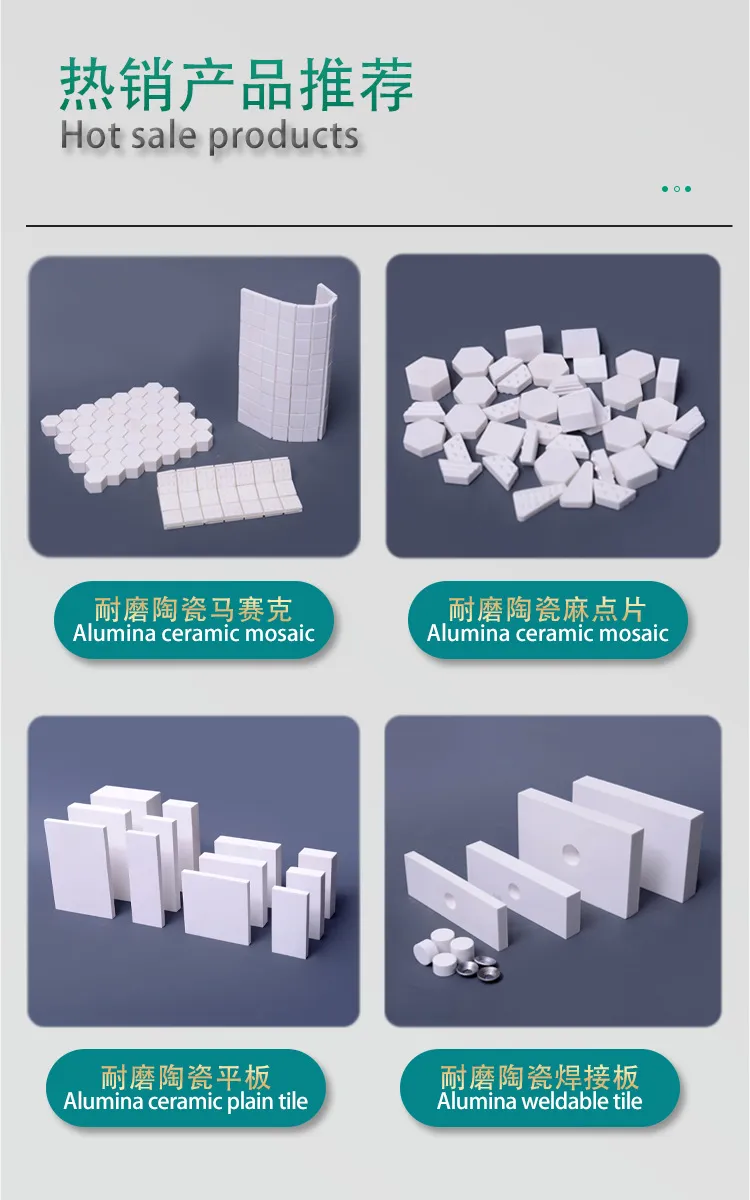

Hot Selling Ceramics

Packaging & Shipping

${currentPro.title}