High Alumina Ceramic Wear Lining for Bucket Wheel and Coal Mill

Description

Overview

Basic Info.

- Material: Aluminum

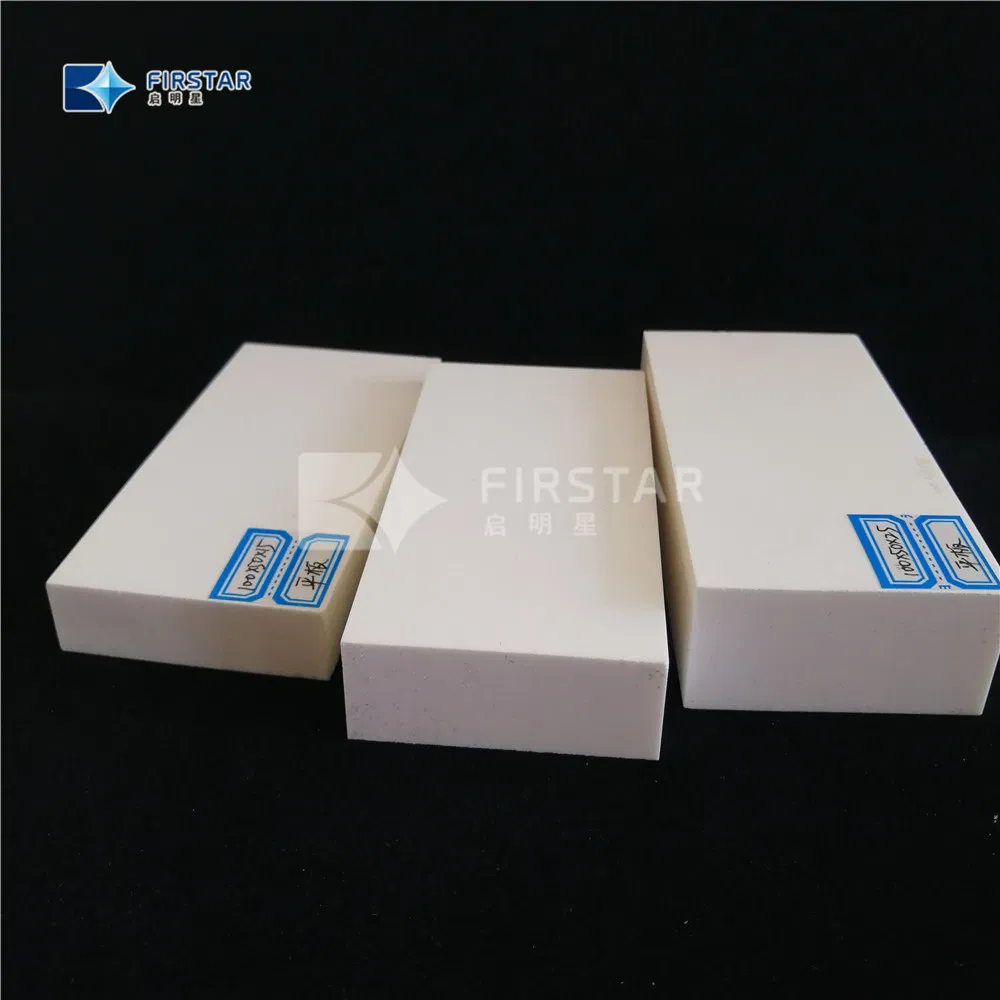

- Type: Wear Resistant Plate

- Color: White

- MOQ: 50kg

- Delivery Time: 15~25 Days as Your Request

- Samples: Free Samples Can Be Provided

- Transport Package: Safe Carton with Pallet

- Specification: as your request

- Origin: China

- HS Code: 6909120000

- Production Capacity: 18000 Tons/Years

Product Description

99% High alumina Ceramic Wear lining for Bucket Wheel and Coal Mill

Abrasion Resistant Alumina Ceramic Lining: Fine grain, high-grade alumina ceramic is the industrial workhorse material for combating sliding and fine particle abrasion. Alumina ceramic has a proven track record in providing excellent value in many of the most troublesome wear applications and is typically very economical and appropriate in many environments. Alumina ceramic is versatile in that it can be pre-engineered into complex tiling systems and can be applied from very thin linings of just 1.5mm or 1/16" thick up to 76mm or 3" thick. Additionally, alumina can be formed into large monolithic pieces and cylinders that can create extremely effective abrasion resistant linings for elbows, pipes, tees and wye fittings. These linings typically outlast other solutions, like chrome carbide or AR plate by 10 times the wear life and with less weight.

Abrasion Resistant Alumina Ceramic: Critical to ensuring the success of any lining is its correct installation or application. Time and experience proven application methods include installing liners using epoxy, weld in tiles, RTV silicone, high temperature mortars, interference and shrink fit, bolt in, key arched designs. QMX is unmatched in its ability to supply custom engineering ceramic liners, which enables us to provide a more precise fit and full ceramic protection. The result is a superior wear system. These liners can be formed from monolithic ceramics or take the form of integrated tile systems cut in the green state to fit even the most complex fabrications. Selection of the appropriate lining method can mean the difference between success and failure in any application. Typical applications for these ceramic

Product Parameters

| Category | HC90 | HC92 | HC95 | HCT95 | HC99 | HC-ZTA | ZrO2 |

|---|---|---|---|---|---|---|---|

| Al2O3 | ≥90% | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | / | ≥21% | ≥95% |

| Density | ≥3.50g/cm3 | ≥3.60g/cm3 | ≥3.65g/cm3 | ≥3.70g/cm3 | ≥3.83g/cm3 | ≥4.10g/cm3 | ≥5.90g/cm3 |

| Water Absorption | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% |

| HV 20 | ≥900 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| Rock Hardness HRA | ≥80 | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Bending Strength MPa | ≥180 | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Compression strength MPa | ≥970 | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Fracture Toughness KIc MPam 1/2 | ≥3.5 | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Wear Volume | ≤0.28 cm3 | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 | ≤0.10 cm3 | ≤0.05cm3 | ≤0.02cm3 |

${currentPro.title}