EN

Language

All categories

Product ID: 68594639

Standard Stock 1001 Taper Bush

Contact Now

Description

Overview

Basic Info.

- Model NO. 1001

- Manufacturing Process Casting

- Material Carbon Steel

- Surface Treatment Polishing

- Application Chemical Industry, Grain Transport, Mining Transport, Power Plant

- Bore Size Demands

- Screw with

- Shaft Demands

- Bush Demands

- Standard DIN/ISO

- Transport Package Cartoon Box/Wooden Box

- Trademark HRSY

- Origin Tianjin

- HS Code 8483900090

Product Description

Product Name

Taper lock bushing

Material

Steel, Cast iron, Stainless steel

Color

Black, Natural

Application

Accopanying sprocket, V-type pulley, Timing pulley, Gear etc

Inspection

100%

> INSTALL

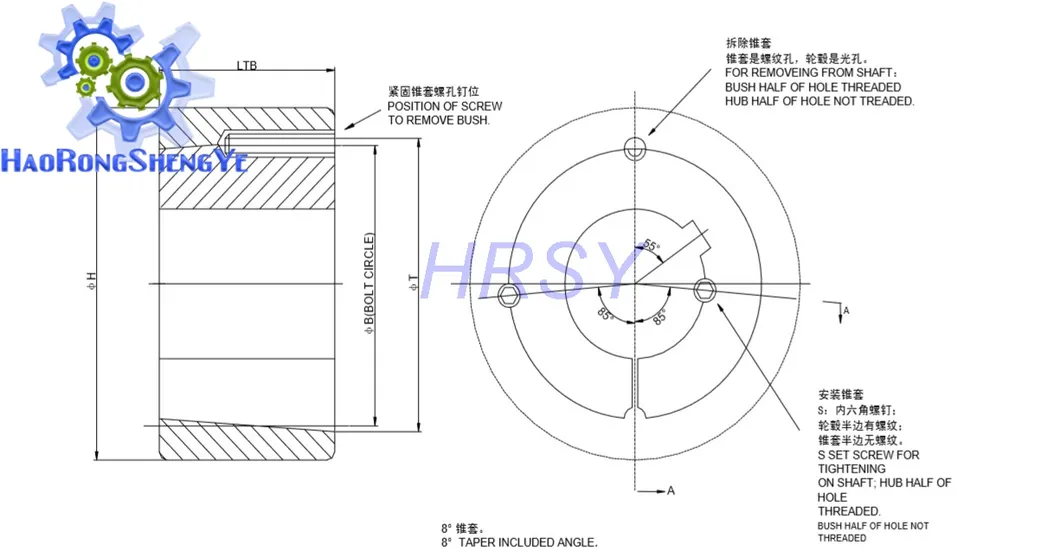

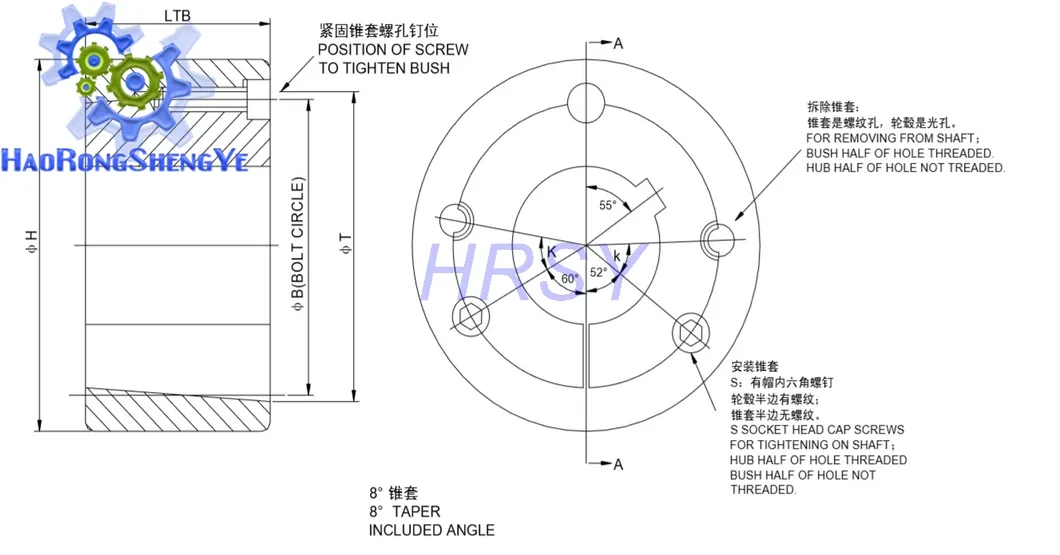

- Clean shaft, bore and outside of bush, and bore of hub. Remove any oil, lacquer or dirt. Place bush in hub and match half holes to make complete holes (each complete hole will be threaded on one side only).

- Lightly oil thread and point of set screws, or thread and under head of cap screws. Place screws loosely in holes that are threaded on hub side.

- Make sure bush is free in hub. Slip assembly onto shaft and locate in the desired position.

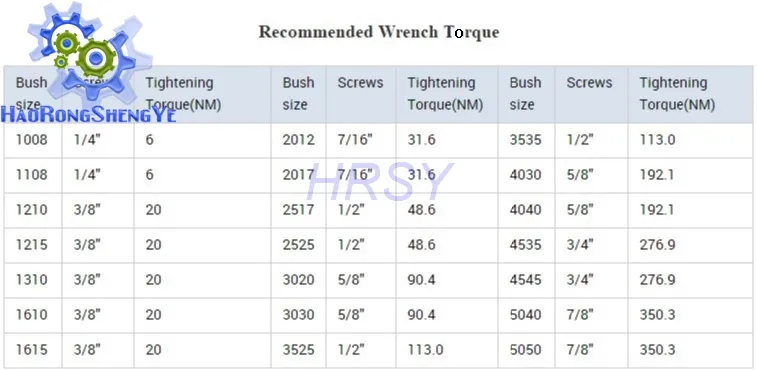

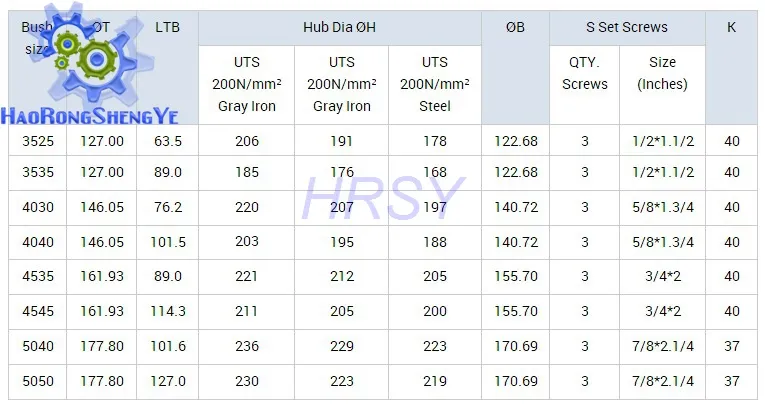

- Tighten screws alternately and evenly until all are pulled up tightly (See table for torque settings).

- Hammer against large end of bush using hammer and block or sleeve to avoid damage. Screws can now be turned a little more to the specified torque setting. Repeat this alternate hammering and screw re-tightening until the specified torque is reached. Fill all holes with grease to exclude dirt.

> REMOVE

- Remove all screws. Lightly oil thread and point of set screws, or thread and under head of cap screws.

- Insert screws into removal holes that are threaded on the bush side. In sizes where washers are found under screws heads, be sure to use these washers.

- Tighten screws alternately until bush is loosened in hub and then remove the complete assembly. If bush does not loosen immediately tap on hub.

Packaging & Shipping

Contact Now

Please Send Message

${currentPro.title}