Automatic PVC Wire Coating Machine for Making Hangers

Description

Overview

Basic Info.

- Model NO. TOPS-PWM

- Type PVC Wire Coating Machine

- Coating Painting

- Substrate Steel

- Certification ISO

- Condition New

- Wire Diameter 0.4-4mm

- Core Components PLC, Motor

- Weight 2000kg

- Coating Material PVC PE

- Color as Client Requirement

- Floor Area Needed 18mx5mx2m

- Transport Package No Packing

- Trademark TOPS

- Origin China

- HS Code 84633000

- Production Capacity as Requirement

Packaging & Delivery

- Package Size 200.00cm * 50.00cm * 150.00cm

- Package Gross Weight 500.000kg

Product Description

Pvc Coated Wire Making Machine

Features: Pvc coated wire making machine is used for PVC or PE coating of black iron wire, electro galvanized wire, hot-dipped galvanized wire and protection of electric wire, cables and others.

Product application: Pvc coated wire is widely used in animal breeding, agriculture and forestry protection, aquaculture, park zoo enclosure, stadium, etc. It is anti-corrosion, anti-aging, longer life than ordinary wire.

Product Parameters

- Machine is fully automatic machine that could produce PVC coating on Iron Wire or Galvanized Wire.

- The coating thickness is according the mould, we can do the mould according to customer's requirement.

- Finished wire is top quality, the bonding between the iron wire and the PVC is strong and the PVC coating is glued to the iron wire and will not be loose.

- Machine production capacity is 70 to 100kg per hour.

- The machine supplied with all new components.

Model No.

- TOPS-XM45

- TOPS-XM65

Wire diameter

- 0.55mm - 1.2mm before coated

- 1.0mm - 2.0mm after coated

- 1.2mm - 4.0mm before coated

- 2.0mm - 5.5mm after coated

Motor power

- 5.5kw

- 15kw

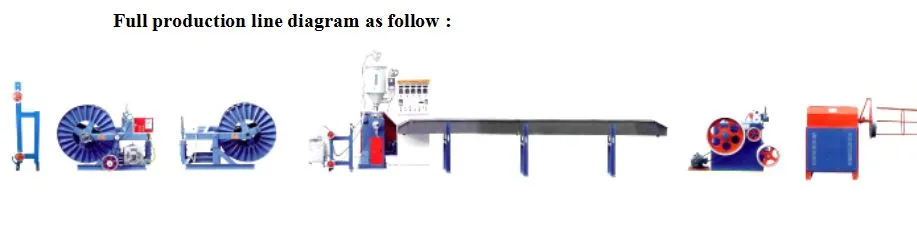

Production Process

Production Line Configuration Tension device → Wire winding machine → Pay off machine → Tension device → XM65 Plastic Extruder → Temperature control cabinet → Water channel → Tractor for take up → Take up machine

Detailed Photos

wire winding machine with tension device spool type pay-off device electric cabinet

(we can also make wire coil type pay-off device for customers if needed)

tension device plastic extruder water channel

tractor for take-up device take-up device finished PVC wire

(we can also make trunk type take-up device or spool type take-up device according to customers requirements)

Packaging & Shipping

${currentPro.title}