EN

Language

All categories

Product ID: 68589896

Inclined Sidewall Corrugated Belt Conveyor Factory

Contact Now

Description

- Overview

- Product Parameters

Basic Info.

Model NO.

DJB

Structure

Belt Conveyor

Material

Carbon Steel

Material Feature

Oil Resistant, Heat Resistant, Fire Resistant

Application

Chemical Industry, Grain Transport, Mining Transport, Power Plant

Condition

New

Model

Djb

Belt Width

500/600/800/1000/1200/1400mm

Speed Range

1.0m/S~4.0m/S

Conveying Angle

30°~90°

Bbaffle Height

75mm~260mm

Side Wall Height

100/120/160/200/240/300mm

Baffle Shapes

C/T/Tc/Tcs

Distance Between Baffles

126/252/378mm

Particle Range

50mm~450mm

Capacity

84~5736m3/H

Transport Package

Standard Shipping Package

Trademark

PK

Origin

Henan, China (Mainland)

HS Code

8428330000

Production Capacity

2000 Sets/Year

Product Description

inclined sidewall large angle corrugated belt conveyor

Introduction

Sidewall belt conveyors are the best solution for horizontal, sloping or vertical product transport. It adopts high quality conveyor belt with corrugated sidewall and horizontal baffle. Sidewall belt conveyor is widely applied in coal and wood-chip fired power stations, underground mining (coal and ore),steel industry, ship loading and unloading, foundry plants, silo feeding industry, waste recycling, soil purification and water treatment, etc.

Advantages and Features

1.No spillage with steep angle conveying,long lifespan

2.Larger production grain sizes can be handled

3.Reduced energy consumption to save money for you

4.Able to conveyor material at any angles up to 90 degree to save space for you

5.Higher conveyance capacity

6.Extremely high stability is provided in the traverse direction, good longitudinal flexibility

7.Low maintenance requirements

8.Hot vulcanization provides 5 times greater adhesion between the belt and sidewall, eliminating the need for bolting the sidewall to the base belt.

9.Can be sealed and environmental friendly

Technical Parameter

Technical Parameter

Capacity is under 45° angle and belt speed 1m/s.

Note: All the parameters are for reference only, we can design and manufacture as per your requirements.

Selection Conditions

We mainly provide the following equipments :

Introduction

Sidewall belt conveyors are the best solution for horizontal, sloping or vertical product transport. It adopts high quality conveyor belt with corrugated sidewall and horizontal baffle. Sidewall belt conveyor is widely applied in coal and wood-chip fired power stations, underground mining (coal and ore),steel industry, ship loading and unloading, foundry plants, silo feeding industry, waste recycling, soil purification and water treatment, etc.

Advantages and Features

1.No spillage with steep angle conveying,long lifespan

2.Larger production grain sizes can be handled

3.Reduced energy consumption to save money for you

4.Able to conveyor material at any angles up to 90 degree to save space for you

5.Higher conveyance capacity

6.Extremely high stability is provided in the traverse direction, good longitudinal flexibility

7.Low maintenance requirements

8.Hot vulcanization provides 5 times greater adhesion between the belt and sidewall, eliminating the need for bolting the sidewall to the base belt.

9.Can be sealed and environmental friendly

Technical Parameter

Technical Parameter

| Belt Width (mm) |

Sidewall Height (mm) |

Particle Range (mm) |

Speed Range (m/s) |

Capacity (m3/h) |

| 500 | 80 | 50-100 | 0.8-1.25 | 31 |

| 500 | 100 | 55-110 | 0.8-1.25 | 44 |

| 500 | 120 | 60-120 | 0.8-1.25 | 58 |

| 650 | 100 | 55-120 | 0.8-1.6 | 61 |

| 650 | 120 | 60-140 | 0.8-1.6 | 64 |

| 650 | 160 | 80-160 | 0.8-1.6 | 67 |

| 800 | 120 | 60-140 | 0.8-1.6 | 85 |

| 800 | 160 | 80-180 | 0.8-1.6 | 91 |

| 800 | 200 | 100-200 | 0.8-1.6 | 95 |

| 1000 | 160 | 80-180 | 1.0-2.5 | 122 |

| 1000 | 200 | 100-250 | 1.0-2.5 | 133 |

| 1000 | 240 | 140-280 | 1.0-2.5 | 199 |

| 1200 | 160 | 80-200 | 1.0-3.15 | 101 |

| 1200 | 200 | 100-250 | 1.0-3.15 | 167 |

| 1200 | 240 | 140-280 | 1.0-3.15 | 250 |

| 1200 | 300 | 160-310 | 1.0-3.15 | 354 |

| 1400 | 200 | 100-250 | 1.0-3.15 | 301 |

| 1400 | 240 | 140-280 | 1.0-3.15 | 350 |

| 1400 | 300 | 160-350 | 1.0-3.15 | 431 |

| 1400 | 400 | 200-350 | 1.0-3.15 | 566 |

| 1600 | 200 | 100-250 | 1.25-3.15 | 352 |

| 1600 | 240 | 140-280 | 1.25-3.15 | 440 |

| 1600 | 300 | 160-350 | 1.25-3.15 | 507 |

| 1600 | 400 | 200-350 | 1.25-3.15 | 751 |

| 1800 | 240 | 140-280 | 1.25-3.15 | 401 |

| 1800 | 300 | 160-350 | 1.25-3.15 | 558 |

| 1800 | 400 | 200-350 | 1.25-3.15 | 866 |

| 1800 | 500 | 300-450 | 1.25-3.15 | 1067 |

Note: All the parameters are for reference only, we can design and manufacture as per your requirements.

Selection Conditions

| ♦Material to be processed: _____ | ♦Max. granule size of the feeding material: _____mm |

| ♦Handling capacity (Ps. It means the total | ♦Percentage of Max. granule in material:_________% |

| material capacity feeding from the inlet): _____t/h | ♦Upstream equipment (Ps. It means what kind of |

| ♦Bulk Density: _____t/m3 | equipment is used to feed the material): _____ |

| ♦Material temperature: _____ºC; | ♦Downstream equipment (Ps. It means what kind of |

| ♦Water content:____% | equipment is used to discharge the material): _____ |

| ♦Material is corrosive or not: ____ (Ps. Yes or No) | ♦Working power supply: _____V ______HZ |

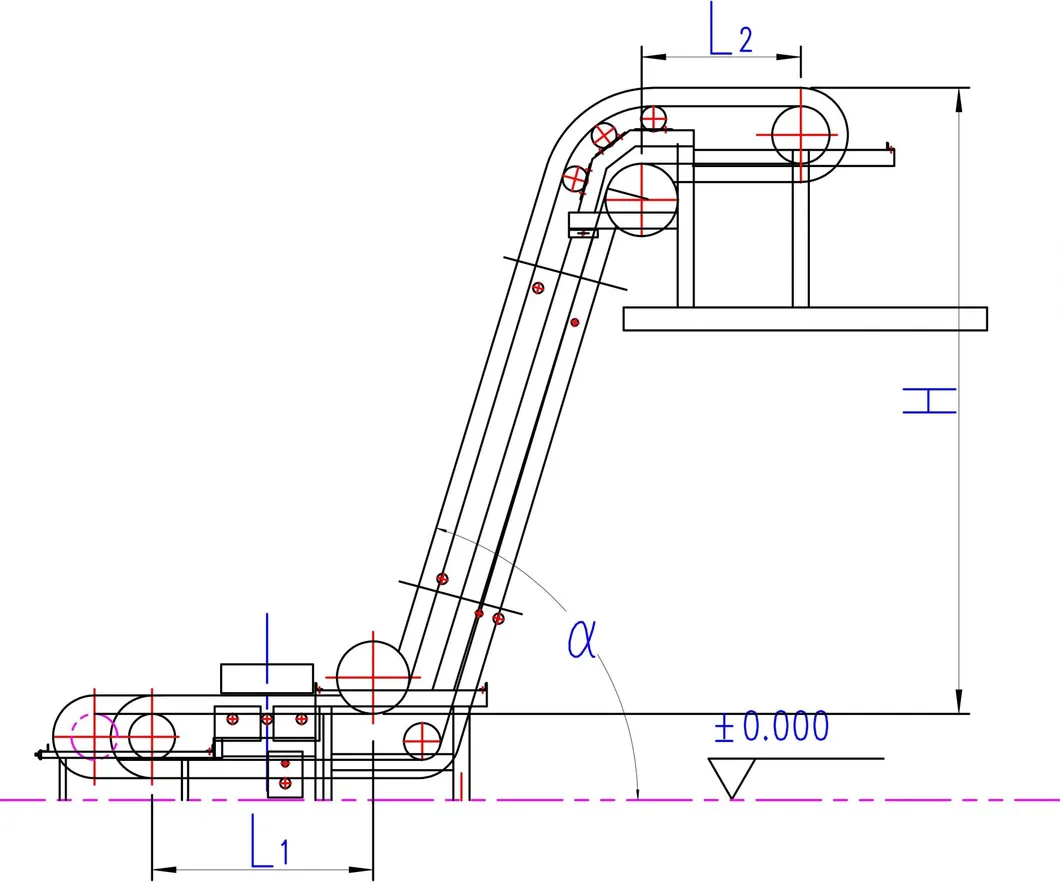

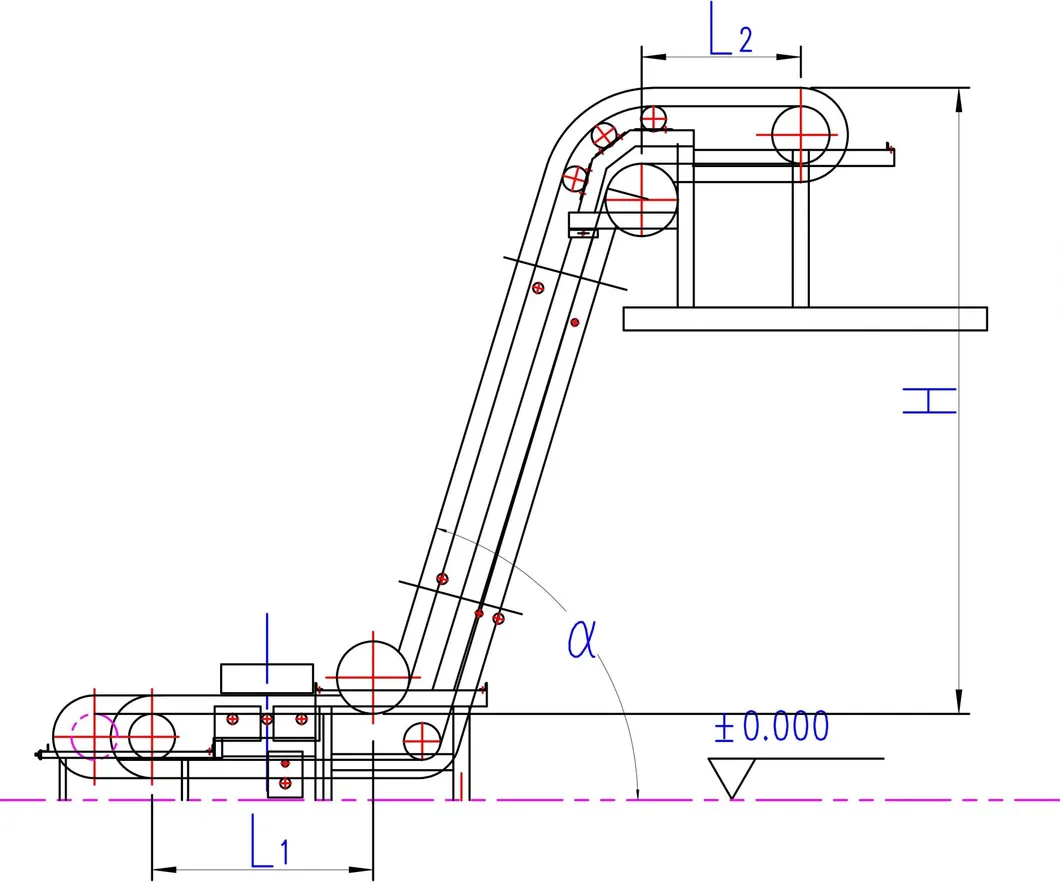

| ♦Material is sticky or not: ____ (Ps. Yes or No) | ♦Please refer to the following picture and provide the |

| ♦Working environment is indoor or outdoor | relevant parameters:L1____m, L2___m, H___m, α____° |

| or indoor and outdoor: ______________ | |

| ♦Working environment temperature: ______ ºC |

We mainly provide the following equipments :

| Vibrating Screen | Rotary vibrating screen |

| Ultrasonic vibrating screen | |

| Gyratory screen | |

| Trommel screen | |

| Linear vibrating screen | |

| Circular vibrating screen | |

| Dewatering screen | |

| Vibrating feeder | |

| Belt Conveyor | Belt conveyor |

| Sidewall belt conveyor | |

| Portable belt conveyor | |

| Shuttle conveyor | |

| Tripper | |

| Bucket Elevator | Efficient bucket elevator |

| Belt bucket elevator | |

| Ring chain bucket elevator | |

| Plate chain bucket elevator | |

| Cement bucket elevator | |

| Silo bucket elevator | |

| Screw Conveyor | U-type screw conveyor |

| Cement screw conveyor | |

| Pipe screw conveyor | |

| Scraper Conveyor | Horizontal scraper chain conveyor |

| Incline scraper chain conveyor | |

| Grain scraper chain conveyor |

Contact Now

Please Send Message

${currentPro.title}