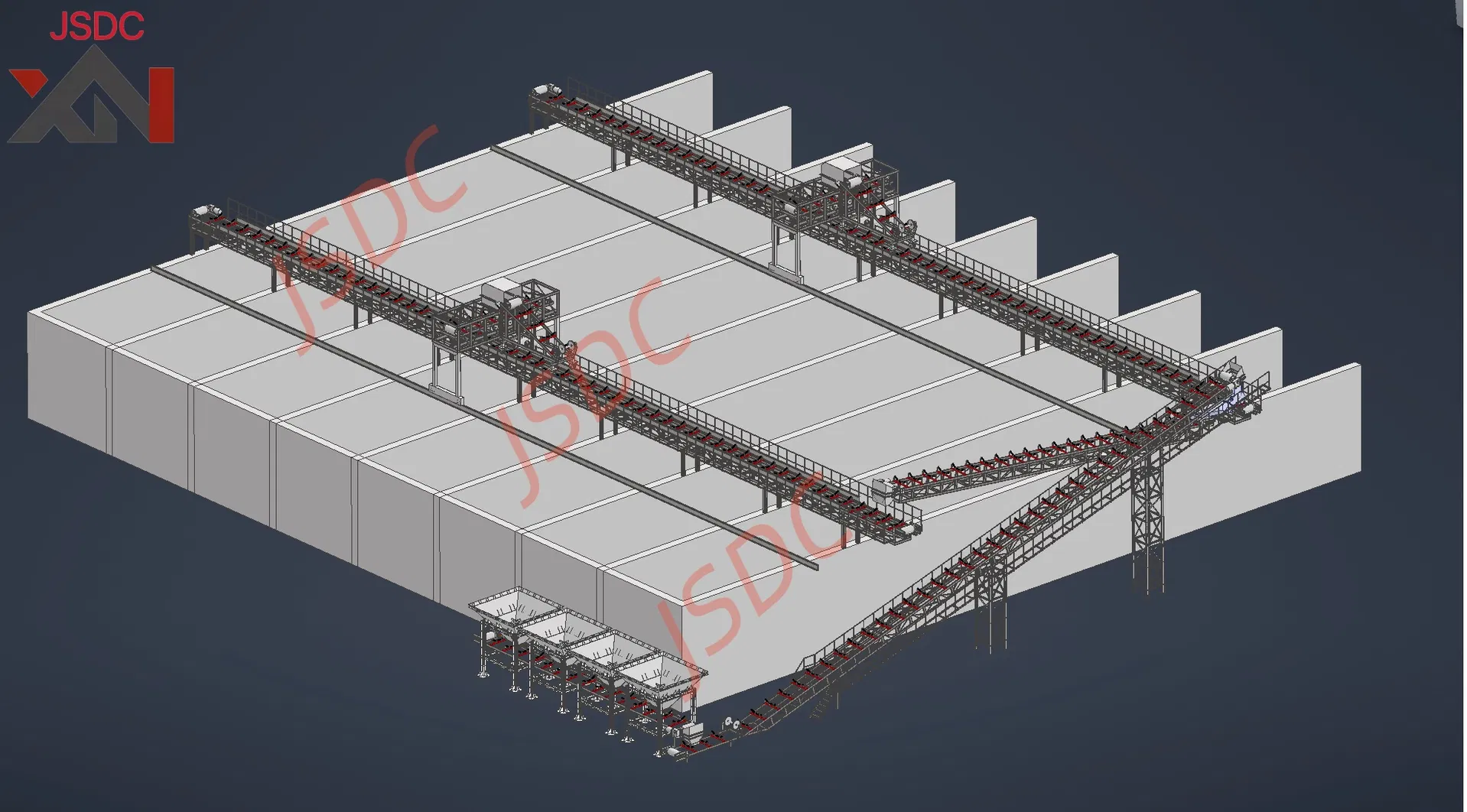

Industrial Conveyor System for Handling Aggregate

Description

Overview

Basic Info.

- Model NO. DTII(A)-JSDC0044

- Structure Conveyor System

- Material Carbon Steel

- Material Feature Oil Resistant, Heat Resistant, Fire Resistant

- Application Chemical Industry, Grain Transport, Mining Transport, Power Plant

- Condition New

- Paint Color Customized

- Installation at Site

- Capacity 10-6000 T/H

- Material Bulk Density 0.1-5.0t/M³

- Transport Package Nude Packing

- Specification B500-B2400

- Trademark JSDC

- Origin Xian, Shanxi

- HS Code 8428330000

- Production Capacity 80 Sets /Year

Product Description

Jiangsu Dazzling Conveyor Belt Co., Ltd. Founded in 2015, JSDC specializes in manufacturing belt conveyor systems for mining, ports, and bulk material industries, providing top-notch material handling solutions. With nearly a decade of expertise, we craft high-efficiency conveyor systems designed for harsh environments, boasting durable components and energy-saving tech. Widely used in ore plants, port terminals, and industrial projects, our equipment is celebrated for reliability and low maintenance.

Key Features

- Heavy-Duty Construction: Built for continuous use in demanding mining environments.

- High-Quality Components: Trusted brands for motors, reducers, and bearings (customizable).

- Customizable Design: Tailor belt width, length, incline, and capacity to your needs.

- Advanced Safety Features: Equipped with emergency stops, misalignment sensors, and anti-slip devices.

- Energy Efficient: Optimized design to minimize power usage.

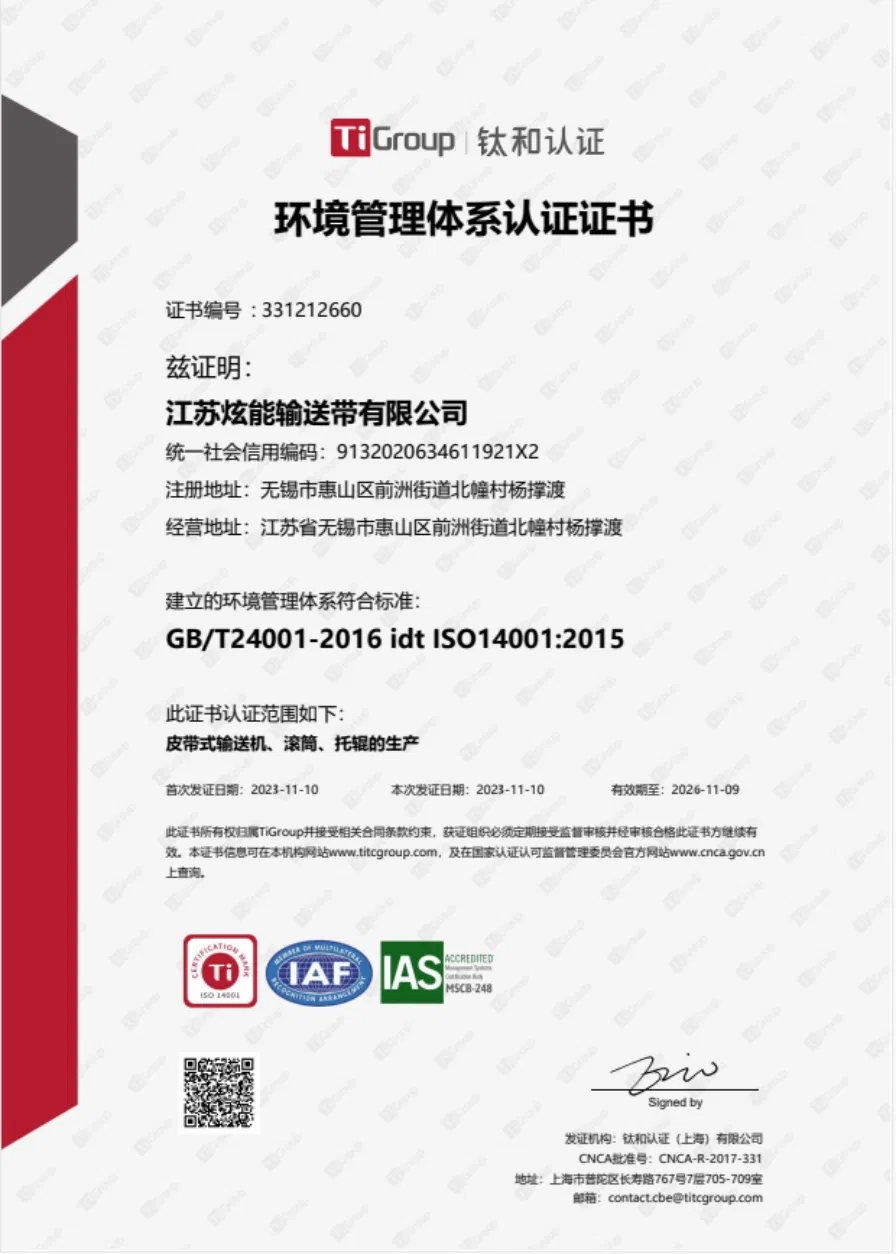

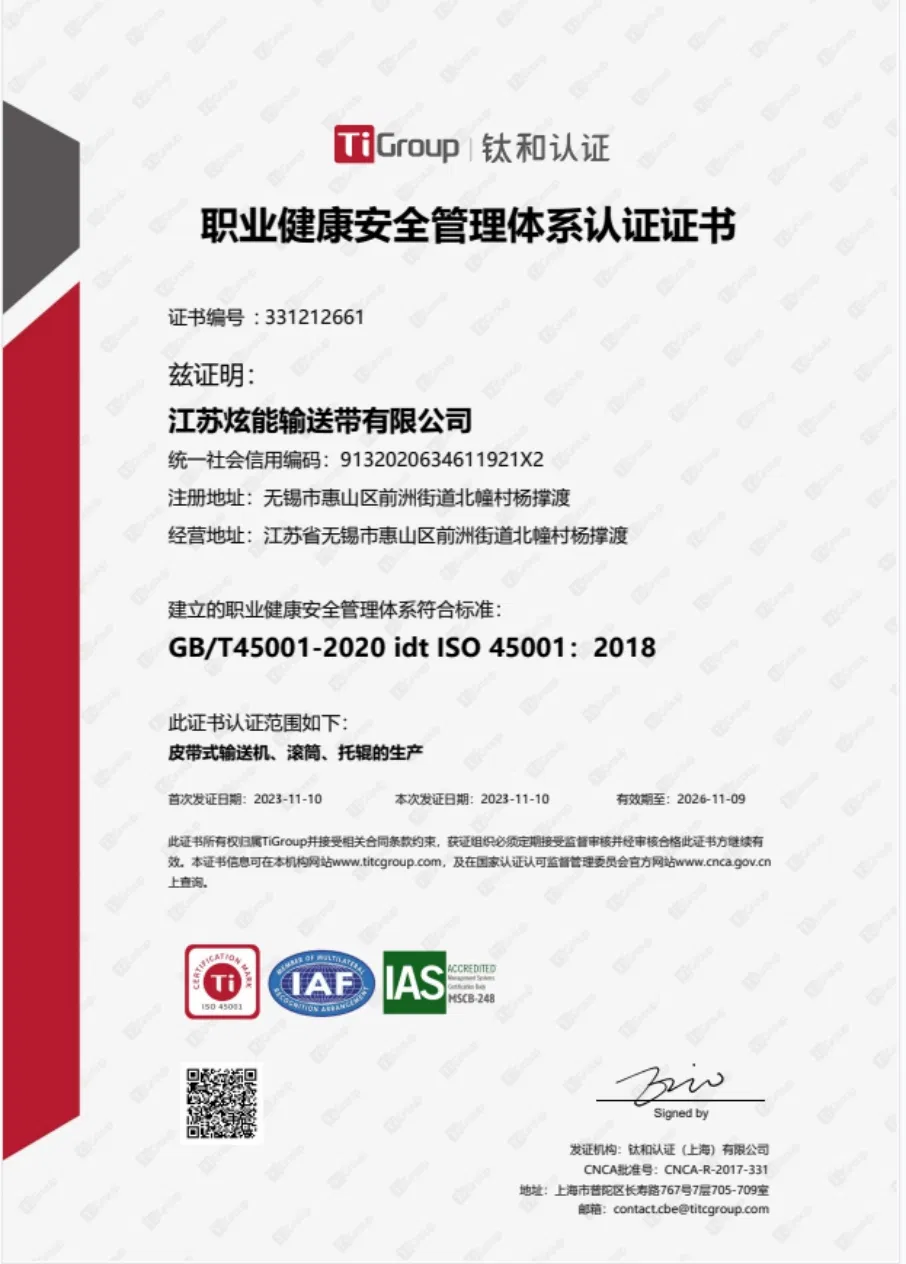

- CE & ISO Certified: Complies with international quality and safety standards.

Design & Advantages

Specification

- Capacity 10T---6000T/H

- Materials Sand and gravel aggregates, coal, sludge, fertilizers, salt, cement, and so on

- Material bulk density 0.1-5.0t/m³

- Belt conveyor

- Belt width B500, B650, B800, B1000, B1200, B1400, B1600, B1800, B2000, B2200, B2400

- Belt Speed 0-4.0m/s

- Ordinary nylon belt model EP100, EP150, EP200, EP250, EP300, EP350, EP400 ST1000

- Steel wire belt model ST630, ST800, ST1000, ST1250, ST1600, ST2000, ST2500, ST3150, ST4000

- Belt selection formula (Motor power * 6000)/bandwidth mm * (1.1-1.3) coefficient

- Belt thickness 10mm-25mm

- Belt length 1m-100000m

- Luffing angle Flat belt conveyor 0-21°, patterned belt conveyor 0-30°, steep angle belt 25-70°

- Driven Customizable: 0.75KW-880KW (low voltage motor and high voltage motor)

- Speed reducer Customizable

- Brake Customizable

- Coupler Customizable

- Coupling Customizable

- Roller Customizable, diameter range Dia 219- Dia 1600mm

- Power Shore power or Diesel engine power generation

Application

Variety of mines & Mining Industry: Ideal for transporting coal, ores, and minerals in open-pit mines.

Ports & Logistics: Efficiently handles bulk cargo like iron ore and grains in ports and shipping yards.

Construction & Building Materials, Metallurgy & Chemical Industry: Transports cement, sand, gravel, and raw materials in cement plants and construction sites. Handles high-temp materials like sintered ore and coke in steel mills and chemical plants.

Professional Installation Team

Why choose us (JSDC), Installation skill: Our certified installation team combines technical expertise with keen attention to detail. With over a decade of experience and advanced training in mining, port conveyors, and more, we ensure seamless deployment to meet your specific needs.

- Skilled Professionals – Licensed technicians adhere to rigorous safety protocols.

- Efficient Execution – 98% on-time completion with minimal disruption.

- Quality Assurance – 12-month warranty on all installations.

- Customer-Centric Approach – From consultation to post-service support.

Transform your space with precision. Contact us today for a free consultation!

Packaging & Shipping

Shipped by containers: Advantages of Bulk Carrier Shipment: No size or weight limits for oversized or uniquely shaped components. Avoids costs of disassembly/reassembly for containerization. Direct Loading Flexibility: Heavy-lift cranes or ramp systems allow direct loading without extra handling. Perfect for ports without container terminal facilities. Cost Efficiency for Bulk Cargo: Freight charged per ton, cost-effective for low-value bulk goods.

Shipped by bulk vessel: Advantages of Container Shipment: Standardized Protection: Steel containers offer weatherproof and anti-corrosion protection for precision parts. Cuts transit damage by 60-80% compared to bulk transport. Operational Efficiency: Automated handling reduces port time by 70% compared to bulk loading. Pre-loaded containers support just-in-time delivery.

ISO Certifications

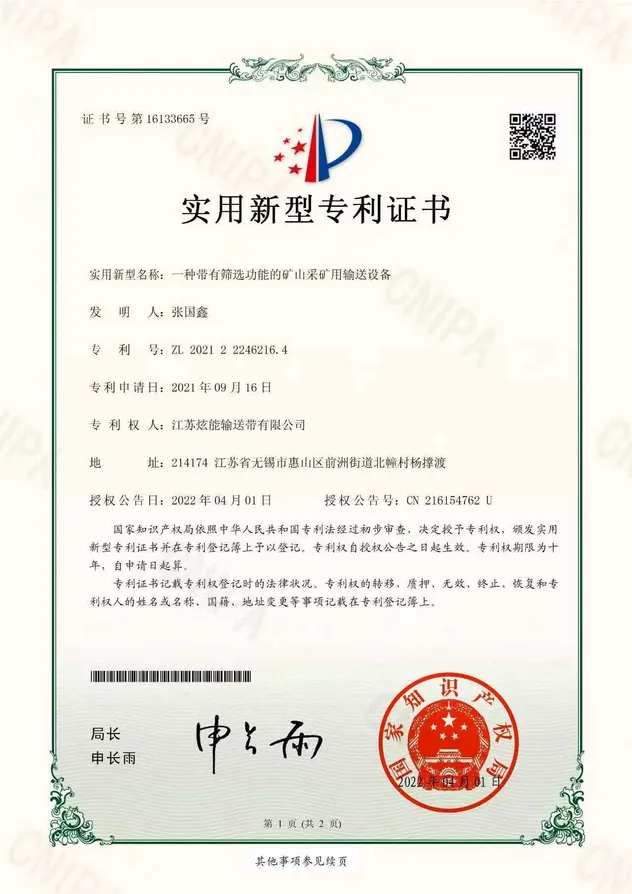

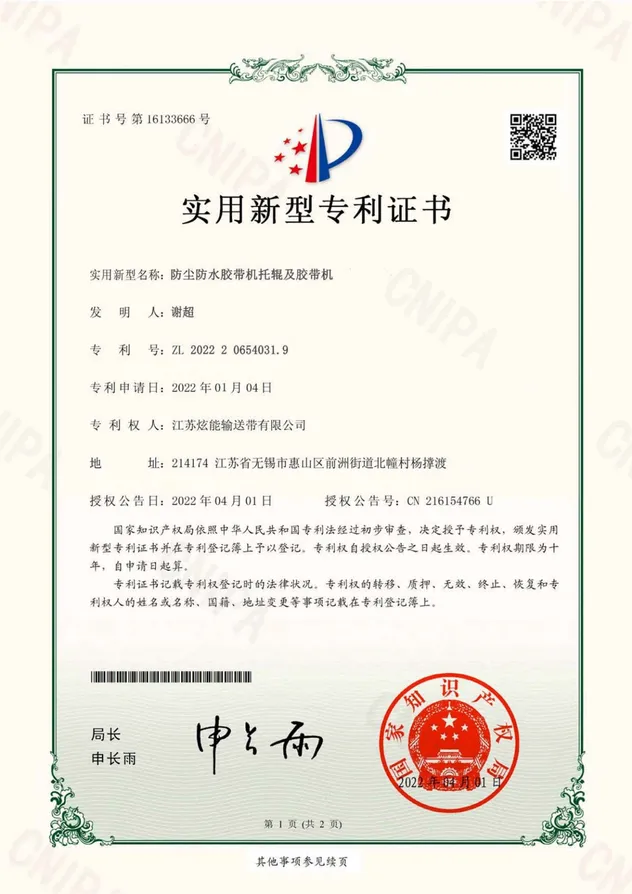

Patents

FAQ

- Basic Information

- 1.1 Your role in the project: Engineer, Purchaser, Maintenance Manager, Other:_________

- 1.2 Industry of application: Mining, Power Plant, Recycling/Waste Management, Other:_________

- 1.3 Materials this belt conveyor will handle: Coal, salt, sand, coke, grain, other:_________

- Technical Requirements

- 2.1 Expected belt capacity: <100 tph, 100-500 tph, 500-1000 tph, >1000 tph

- 2.2 Required belt width: 500mm, 650mm, 800mm, 1200mm, Custom:_________

- 2.3 Preferred drive type: Electric, Hydraulic, Other:_________

- Environmental Conditions

- 3.1 Operating environment: Indoor, Outdoor (weatherproof needed) Harsh conditions (corrosion/dust)

- 3.2 Temperature range: -20°C to 40°C, -40°C to 60°C, Extreme conditions:_________

- Customization Needs

- 4.1 Required safety features: Emergency stop, Belt misalignment sensors, Fire suppression, Other:_________

- 4.2 Special materials: Food-grade, Anti-static, Abrasion-resistant, Other:_________

- Additional Comments

Please specify any unique requirements or constraints:

${currentPro.title}