Factory Price Intelligent Logistics Truck Loading Unloading WMS Telescopic Belt Conveyor **Title:** Intelligent Logistics Truck Loading Conveyor System

Description

Overview

Basic Info.

- Model NO. telescopic belt conveyor

- Structure Belt Conveyor

- Material Rubber

- Material Feature Oil Resistant, Heat Resistant, Fire Resistant, Strong and Durable

- Application Chemical Industry, Grain Transport, Mining Transport, Power Plant, Cep, E-Commerce Retail, Logistics Warehouse

- Condition New

- Lead Time 15-30

- Shipment by Sea, by Air, by Truck, by Train

- Belt Width 800 mm

- Application Scenario Suitable for All Kinds Of cargo Loading and Unloadi

- Transport Package Standard Export Package

- Specification customized

- Trademark ODM & OEM

- Origin China

- HS Code 8479894000

- Production Capacity 10000unit/Year

Packaging & Delivery

- Package Size 300.00cm * 300.00cm * 300.00cm

- Package Gross Weight 2000.000kg

Product Description

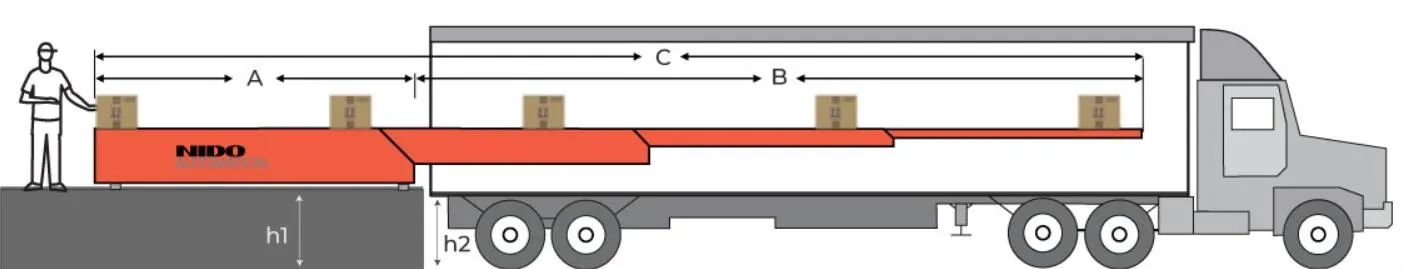

Telescopic Truck Loading Conveyor Introduction: The telescopic truck loading unloading conveyor operates in accordance with human body engineering, which can realize the rapid loading and unloading, suitable for all kinds of freight cars of cargo handling. This telescopic belt conveyor can freely expand and contract in the length direction and control the length of the conveyor at any time. It can transport materials in both directions and can be used in conjunction with other conveying equipment and material sorting systems to realize automated production of materials entering and exiting warehouses or vehicle loading and unloading. It is widely used in various industries.

Truck Loading Conveyor Application

Telescopic truck loading unloading conveyor is suitable for loading and unloading trucks, cartons, woven bags, packages, luggage, tires, plastic boxes/drums, etc.

Truck Loading Conveyor Features

- This conveyor only requires 2 people to move to different working locations at will.

- Push it directly into the car, and can work inside the car about 10 meters deep.

- When this conveyor is operating, the operation can be completed by manually dragging the goods close by, loading the goods in the forward direction, and unloading the goods in the reverse direction. The loading and unloading efficiency can reach about 30 pieces of goods per minute.

- The operating position of the conveyor can be adjusted in various directions according to the operation requirements. Using the original mechanical arm hydraulic device, the height can be raised to 4 meters and the lowest can be lowered to 2 meters, which solves the problem of difficulty in palletizing heavy goods.

| Name | Type | Fixed length-A (mm) | Stretch length-B (mm) | Overall length | Effective Width | Conveying height |

|---|---|---|---|---|---|---|

| Two Sections | XJ-SS-2-3/2 | 3000 | 2000 | 5000 | 800 | 800 |

| XJ-SS-2-5/3 | 5000 | 3000 | 8000 | 800 | 800 | |

| XJ-SS-2-6/4 | 6000 | 4000 | 10000 | 800 | 800 | |

| Three Sections | XJ-SS-3-5/7 | 5000 | 7000 | 12000 | 800 | 800 |

| XJ-SS-3-6/8 | 6000 | 8000 | 14000 | 800 | 800 | |

| XJ-SS-3-7/9 | 7000 | 9000 | 16000 | 800 | 800 | |

| Four Sections | XJ-SS-4-6/12 | 6000 | 12000 | 18000 | 800 | 850 |

| XJ-SS-4-7/14 | 7000 | 14000 | 21000 | 800 | 850 | |

| XJ-SS-4-8/17 | 8000 | 17000 | 25000 | 800 | 900 | |

| Five Sections | XJ-SS-5-6/16 | 6000 | 16000 | 23000 | 800 | 900 |

| XJ-SS 5-7/17 | 7000 | 17000 | 24000 | 800 | 900 |

Company Profile

Advanced Logistics Technologies (Shenzhen) Co., Ltd. is an innovative technology company focusing on smart logistics and smart manufacturing. The Shenzhen company was founded in 2018, it has established sales companies and after-sales outlets in Wuhan, Shenzhen, Dongguan, and Australia, and it has production base in Dongguan China. The company is committed to applying advanced technologies including AI vision, Internet of Things, Big Data, Cloud Computing, 5G, and Neural Networks to smart logistics, and using smart warehouse to platformize closed-loop processes, to help enterprises improve their core competitiveness and creativity.

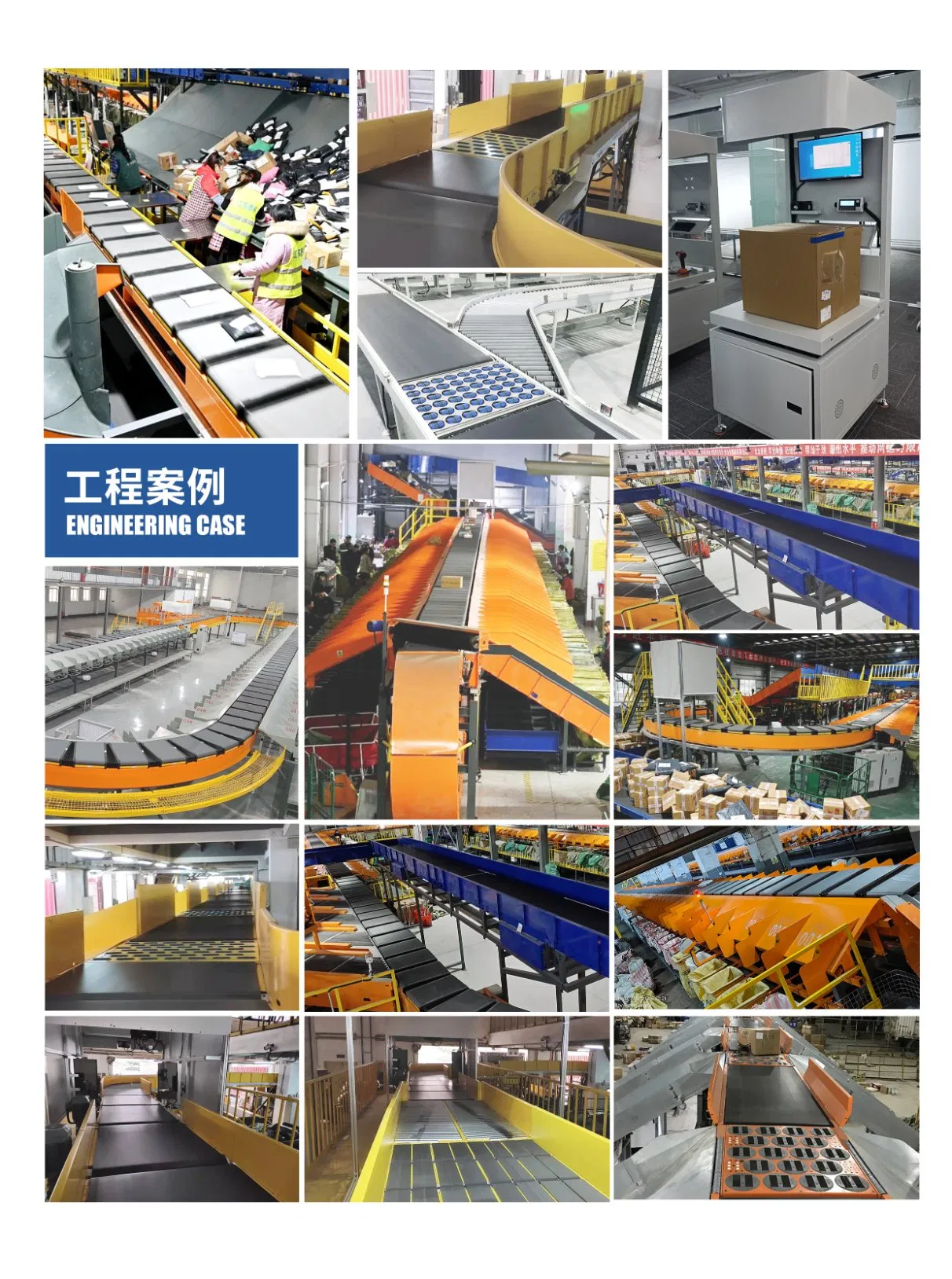

The company R&D team has worked hard and after long-term accumulation and development, its products have covered CEP express logistics, e-commerce, automobiles, pharmaceutical, airports and other fields, covering most provinces and cities across China mainland, and have successfully expanded to Southeast Asia, the Middle East, Australia and other markets. The main products include loop cross-belt sorters, linear cross-belt sorters, linear narrow-belt sorters, balance wheel sorters, Z-shaped sorters, dynamic DWS, static DWS, belt turning machines, belt telescopic conveyors, belt conveyors, all-in-one scanning and weighing volume measurement machines, truck volume measurement equipment, pallet cargo volume and weight measurement equipment and other logistics automated sorting systems and all-in-one warehousing automation management solution.

Engineering Case

Cooperative Customer

Packaging & Shipping

FAQ

- Q1. Are you a trade company or a manufacturing company? We are a manufacturing company.

- Q2. What are your key advantages? As a national high-tech enterprise, Advanced Logistics Technologies Co., Ltd., boasts an in-house software development team that excels in delivering complete, rapid, and efficient R&D solutions. We offer robust OEM and ODM services to cater to diverse customer needs.

- Q3. What services do you provide? Pre-sales: Tailored solutions, meticulous planning and design, personalized one-on-one service. After-sales: Around-the-clock online support, remote installation guidance, seamless integration with customer software systems.

- Q4. What is the warranty period for your products? 12 months.

- Q5. What are your payment terms? We accept T/T, L/C, D/P, D/A, and other flexible payment options.

- Q6. Where is your company located? Our company and factory are both conveniently situated in Guangdong.

${currentPro.title}