Metal Spiral Conveyor Belt System

Description

Overview

Product Description

Basic Info.

- Model NO. JY-B007

- Inside Material Metal

- Feature Oil-Resistant, Heat-Resistant, Cold-Resistant

- Tensile Strength Strong

- Warranty 1 Year

- Showroom Location Philippines, Indonesia, Thailand

- Width or Diameter 1000mm

- Applicable Industries Food & Beverage Factory, Farms, Energy & Mining

- Transport Package Wooden Box

- Specification 30*40*50

- Trademark JOYA

- Origin China

- HS Code 7314140000

- Production Capacity 10000piece/Year

Packaging & Delivery

- Package Size 50.00cm * 30.00cm * 40.00cm

- Package Gross Weight 30.000kg

Product Description

Spiral conveyor belts are designed and manufactured in cookers, transfers, coolers, dryers, freezer tunnels, and more. This mesh belt is made of spiral wire and rods with chain link. For spiral conveyor belts, direct run and curve run are no problem.

For JoYa conveyor belts, they are available with 3/4" or 1" pitch U-shaped side links. And the spiral wires can be very open or tight, or no spiral wire, all these with your requirement. And if you need sprockets, please contact me in time.

Characteristics and Advantage

- Smooth surface for products stability

- Direct run, curve run, positive driven

- Big opening suitable for cool or heat distributor

- Easily cleaned and fitted

- Long working life and short downtime

Specification

- Spiral wire pitch: 5.0mm - 12.7mm

- Rod Pitch: 19.05mm - 27.4mm

- Spiral wire: 1.0mm - 1.6mm

- Rod dia: 5.0mm

- Selvage: welded

- Material: SSS304, SS316

Application

- Transport

- Cooking

- Heating

- Drying

- Cooling

- Drainage

- Freezing

- Elevating

- De-Elevating

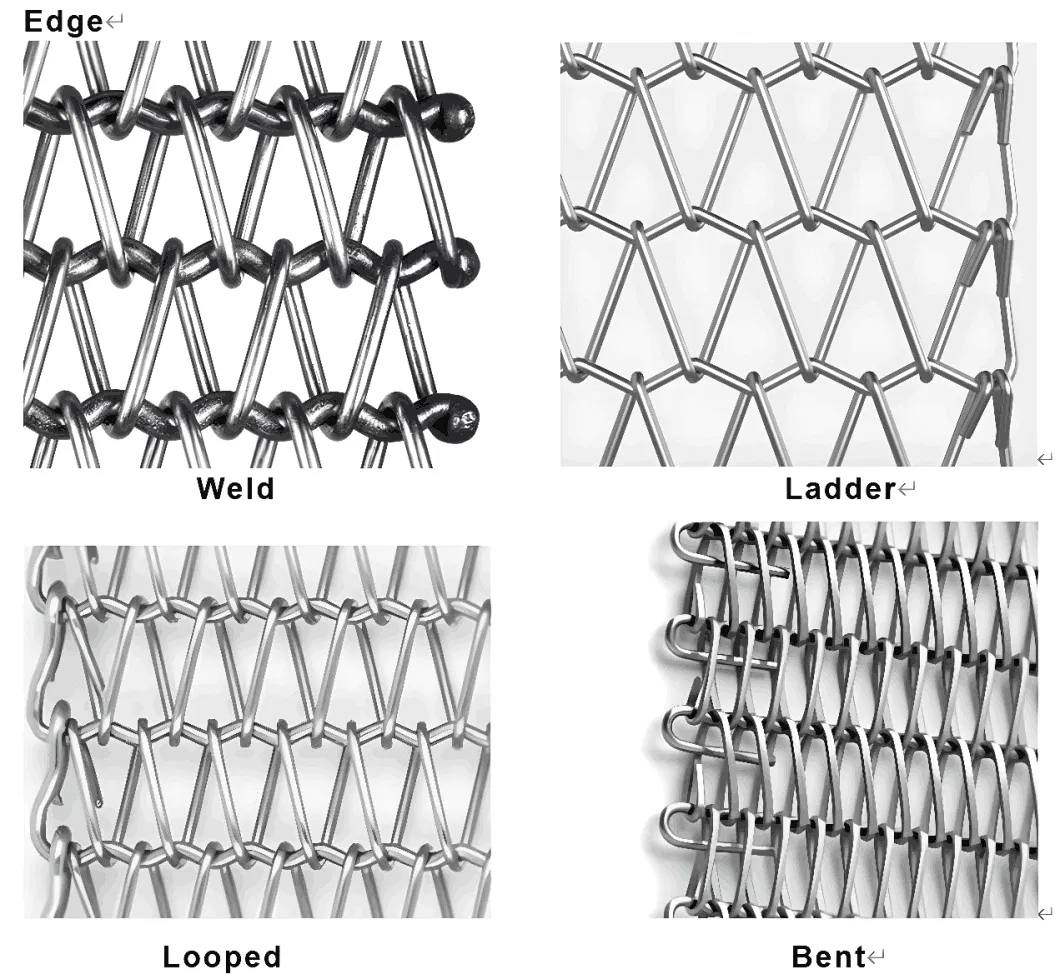

Spiral conveyor belts is an economical and simple metal conveyor belt, widely used in many industries, such as food, beverage, canning, veneer, high temperature and so on. With the different material, the working temperature is from 40 degree to 1500 degree; and take an important application from draining to cooling in food, dryer in veneer, etc. For balance weave belt, it is made of spiral wire and crimped rods, the left and right spiral wires are linked by crimped rods, and the edge is dealt with weld, ladder, knuckled and so on. It is also known as wire link belts, shot blast belts, braided link belts, Balanced Spiral Woven, etc.

Feature and advantage

- Direct driven belt, friction driven

- Smooth belt surface confirm the belt in good status

- Could adjust the open size to suit the transport products size

- Balance weave is simple and economical, used wildly

Specification and photos

- Spiral Wire: from 0.8 to 4 mm

- Pitch of Spirals: from 3 to 33 mm

- Crimped Rods: from 0.8 to 5 mm

- Pitch of crimped rods: from 6.5 to 40 mm

- Belt Width: from 35 to 6000 mm

${currentPro.title}