High Speed Jumbo Roll Slitter Rewinder Machine

Description

Overview

Basic Info.

Model NO. LZPS101

Application Commodity

Type Small Coil Paper Slitting Machine

Work Method Round Knife Cutting

Structure Frame Part

Packaging Film

Classification Paper Cutting Machine

Applicable Process Process Materials

Compatible Substrates Paper

Packaging Material Paper

Size Customized

Condition New

Apply Paper Tissue, Toilet, Kraft... etc

Short HS Code 8441

Transport Package Foam Film

Specification 2800mm

Trademark Leizhan

Origin China

HS Code 8441809000

Production Capacity 50000

Packaging & Delivery

Package Size 300.00cm * 200.00cm * 250.00cm

Package Gross Weight 300.000kg

Product Description

This machine cuts the large-diameter paper roll into different widths paper discs, mainly to meet the needs of the roll tube and various paper processing requirements.

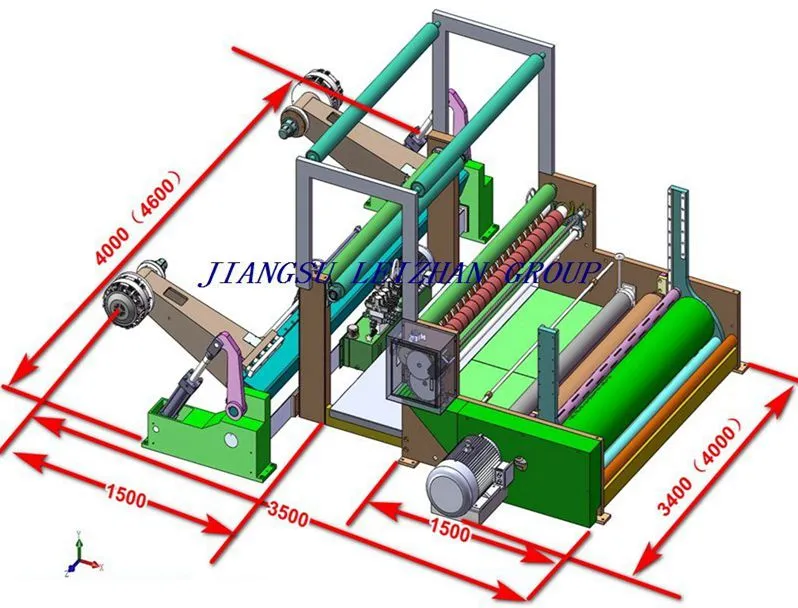

This machine mainly comprises paper unloading device, a paper guiding device, a slitting device, a winding device, a paper unloading device, an electrical control system and other parts.

- Paper unloading device: adopts hydraulic shaftless paper feeding. Multi-point pneumatic brakes on both sides.

- Paper guide device: paper guide roller Φ150mm.

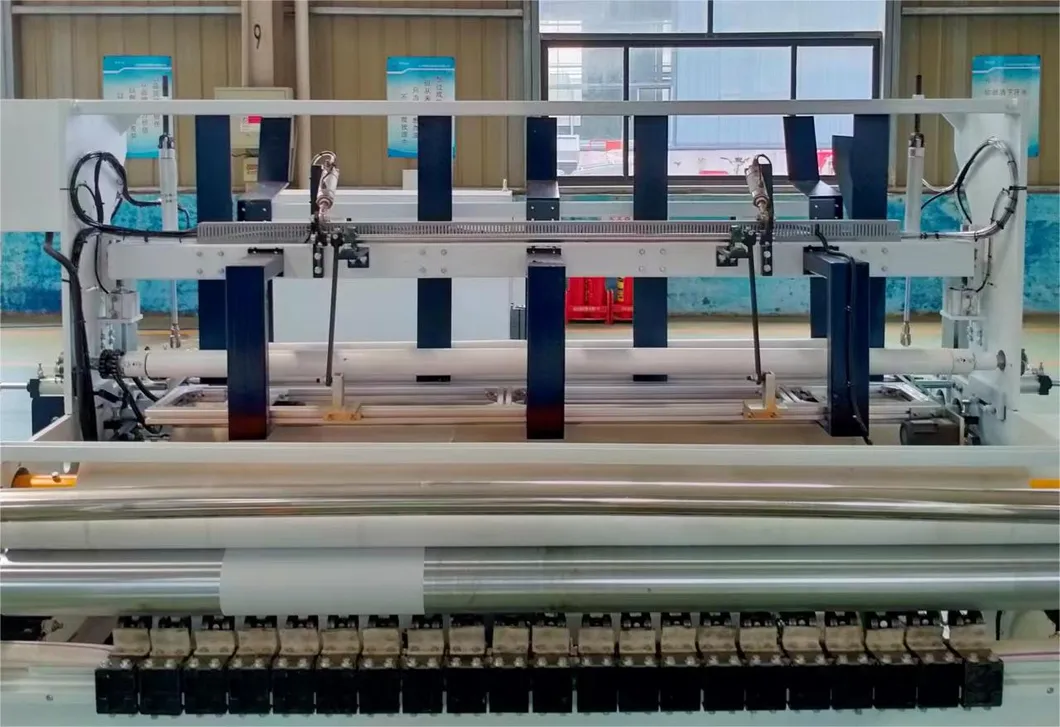

- Slitting device: It is composed of upper knife shaft, lower knife shaft, and upper and lower round knife devices.

- Winding device: including double bottom rollers and wind air expanded roller. The diameters of the double-bottom rollers are Φ313mm and Φ216mm.

- The roller is made of seamless steel with a wall thickness of 15mm, one of which is coat with a polyurethane surface to prevent slippage.

- Paper unloading device: Automatically unload paper hydraulically.

- Electrical control system: mainly includes: frequency converter, touch screen, PLC, electrical proportional valve, solenoid valve, pressure reducing valve, oil-water separator and other pneumatic components, electrical button indicator, contactor, etc.

Feature and Application

Features of slitting rewinding machine

- Adjustable banana (curved) roller to ensure that the paper is easy to separate after slitting.

- The paper roll can be slit and rewind at one time to reduce the waste of joints.

- Through the automatic control of the machine's constant tension, the paper tray has a good tightness and a neat surface.

- The paper is automatically discharged by pneumatic. Easy to operate.

- Frame 40mm thick steel plate is processed in pairs. High precision and good stability.

Application of slitting rewinding machine

Suitable for cutting materials: non-woven fabrics, fireproof fabrics, melted cloth, roll paper, plastic film, leather, PVC, PE industrial materials, chemical materials, composite materials, etc.

Detailed Photos

Product Parameters

| Model | LZ2-650 | LZ2-1300 | LZ2-1700 |

|---|---|---|---|

| Slitting effective width | 30-650mm | 30-1300mm | 30-1700mm |

| Slitting speed | 300m/min | 300m/min | 300m/min |

| Unwinding roll diameter | φ1000mm | φ1000mm | φ1000mm |

| Rewinding roll diameter | 2*φ600mm | 2*φ600mm | 2*φ600mm |

| Main motor power | 4kw | 5.5kw | 7.5kw |

| Rewinding motor power | 5.5kw | 7.5kw | 11kw |

| Total power | 11kw | 13kw | 21kw |

| Precision | ±0.03mm | ±0.03mm | ±0.03mm |

| Machine weight | 2000kg | 3500kg | 4000kg |

| Machine overall dimension | 2700*2000*1580mm | 2700*2650*1580mm | 2800*3150*1600mm |

${currentPro.title}