EN

Language

All categories

Product ID: 68590137

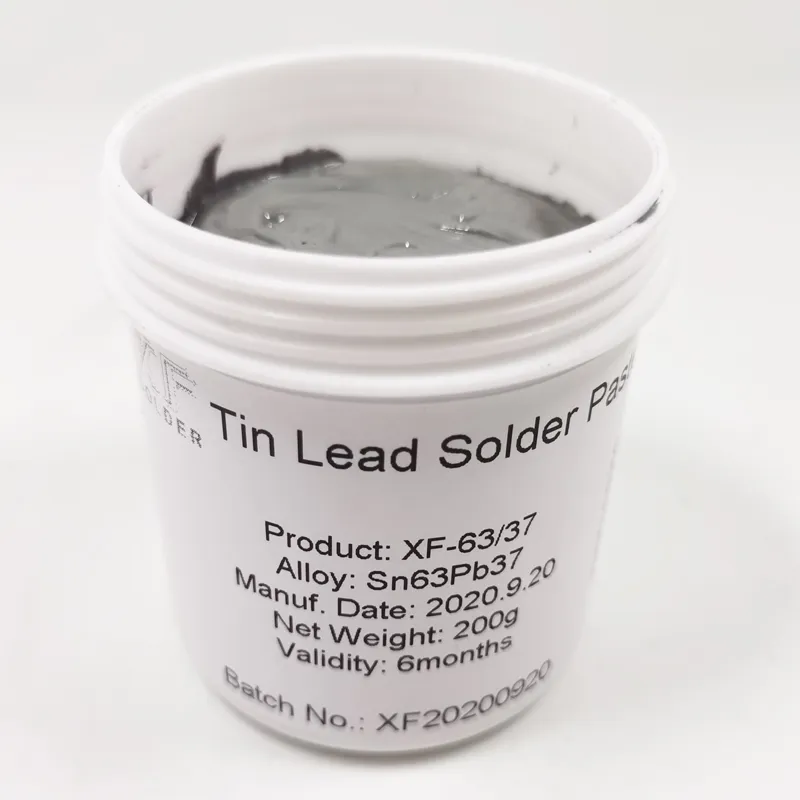

Xf Mechanic SMT SMD Soldering Flux and Paste 63/37 for PCB Welding

Contact Now

Description

Basic Info.

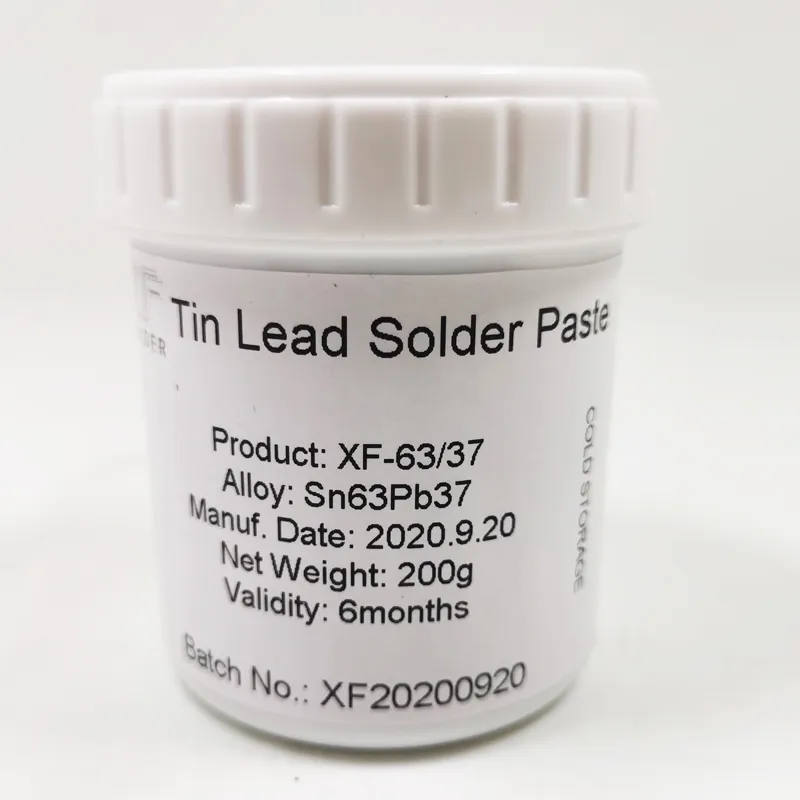

| Model NO. | Solder Paste 63 37 |

| Type | Solder Paste |

| Melting Point | <200℃ |

| Chemical Composition | Sn-Pb |

| Function | Make the Liquid Solder Flow |

| Application | SMT |

| Manufacturing Method | Smelting |

| Alloy | Tin Lead |

| Powder Size | Type 3: 25 to 45 Microns |

| Powder Size 2 | Type 4: 20 to 38 Microns |

| Flux | No Clean Flux |

| Alloy 2 | Sn63pb37 |

| Alloy 3 | Sn60pb40 |

| Alloy 4 | Sn55pb45 |

| Alloy 5 | Sn50pb50 |

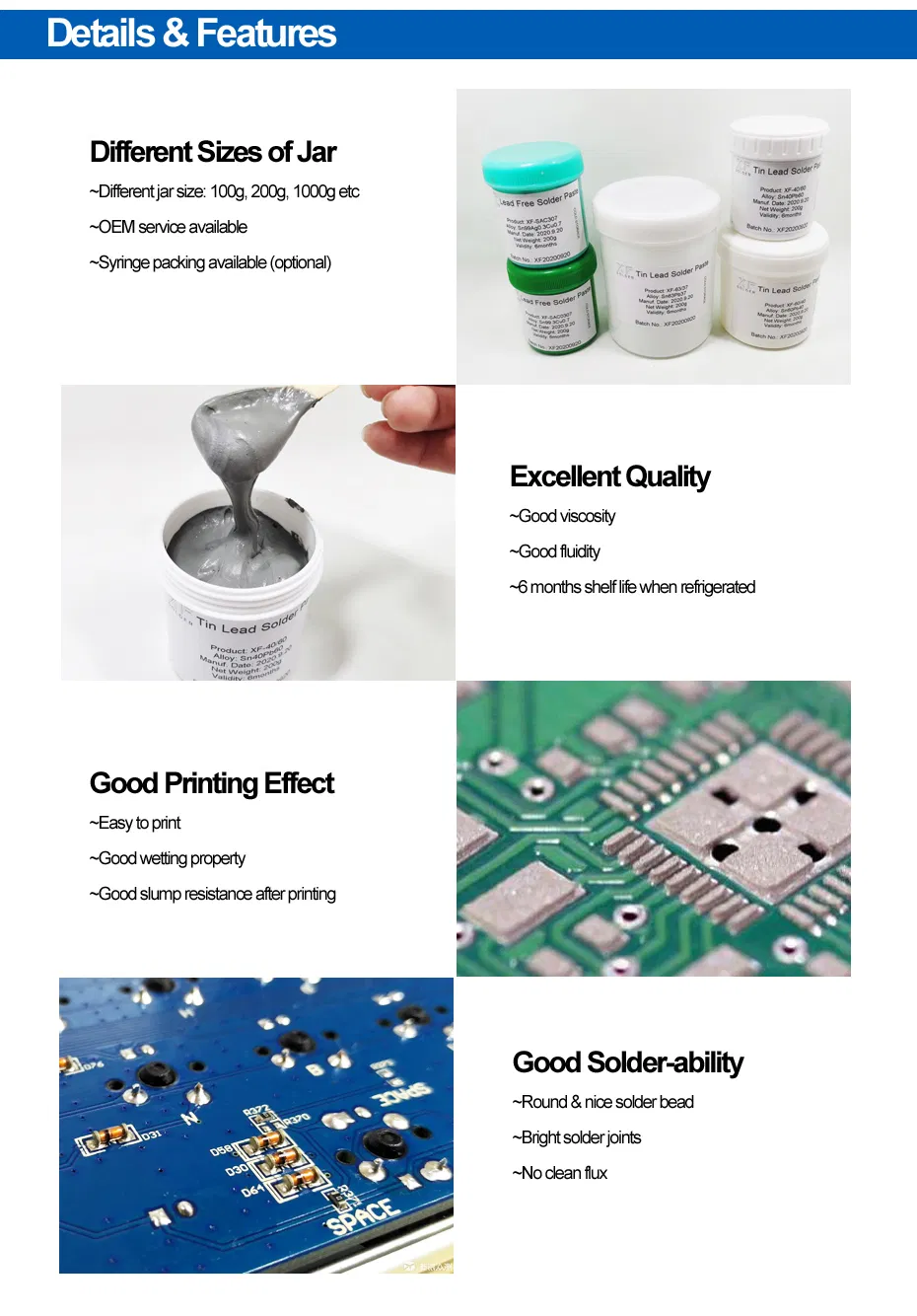

| Packing | Jar |

| Packing 2 | Syringe |

| Shipping | Courier / Air Freight |

| Shelf Life | 6months |

| Storage | 0 to 10 Degree Celsius |

| Application 2 | for SMT Reflow Soldering |

| Application 3 | for PCB Assembly |

| Transport Package | Foam Box |

| Specification | 100g to 1000g |

| Trademark | XF Solder |

| Origin | China |

| HS Code | 3810100000 |

| Production Capacity | 30tons/Month |

Packaging & Delivery

| Package Size | 10.00cm * 10.00cm * 10.00cm |

| Package Gross Weight | 1.000kg |

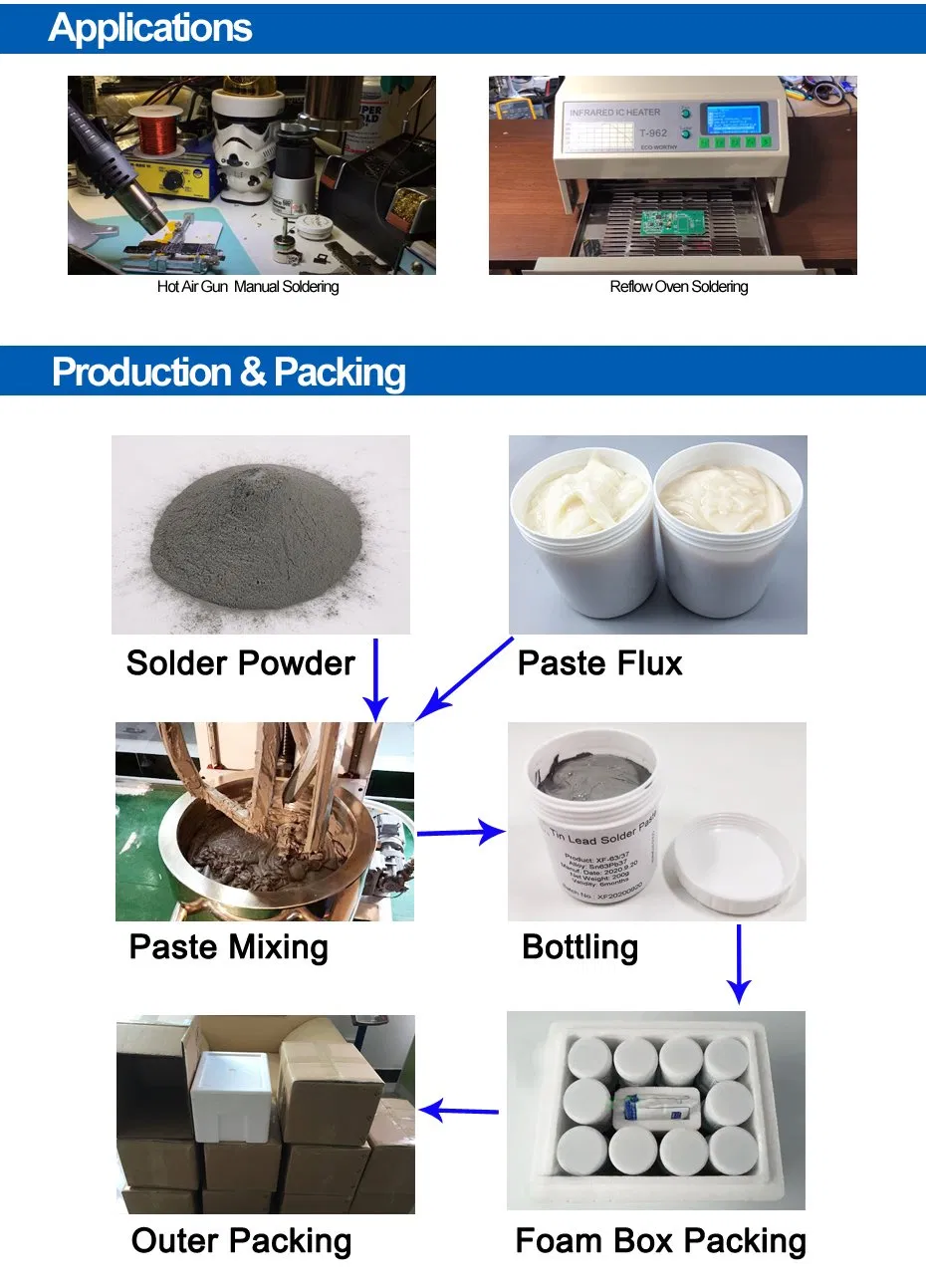

Product Description

Xf Mechanic SMT SMD Soldering Flux Solder Paste 63 37 for PCB Welding

We produce different types of solder paste:

- Lead Free Solder Paste: Sn96.5Ag3.0Cu0.5, Sn99Ag0.3Cu0.7, Sn42Bi58 etc

- Leaded Solder Paste: Sn63Pb37, Sn60Pb40, Sn50Pb50 etc

Applications of Tin Lead Solder Paste Sn63Pb37 63 37:

Sn63Pb37 solder paste can be used in the assembly of consumer electronic products such as smartphones, tablets, laptops, TVs, and audio equipment, LED lighting products etc.

Tin lead solder paste 63 37 can be used in many automotive electronic control units (ECUs), sensors, and modules are assembled using Sn63Pb37 solder paste.

It can be used in industrial electronics such as Industrial automation systems, control panel, solar panels etc.

General soldering and repairing works for small projects or for hobbyist.

How to use Tin Lead Solder Paste Sn63Pb37 63 37?

- Stencil Printing: Prepare and clean stencil and PCB properly. Using a squeegee, a stencil printer, or a similar tool, apply the solder paste 63 37 over the stencil, allowing the paste to be pushed through the openings and onto the PCB pads. Apply even pressure to ensure consistent solder paste deposition.

- Place IC Components: Precisely place surface mount components onto the solder paste-covered pads. Ensure that the component leads or pads align correctly with the solder paste deposits.

- Reflow Soldering: Place the PCB with the components onto a conveyor belt in a reflow oven or onto a hot plate for reflow soldering. The reflow process involves heating the PCB to melt the solder paste 63 37 and create solder joints. Follow the reflowing manual for reflow temperature profiles and times.

Instruction on Storage and Using of Tin Lead Solder Paste Sn63Pb37 63 37:

- It is recommended to store at 2°C to 10°C to prevent paste drying or degradation.

- It's recommended to get the solder paste out of refrigerator 3 to 6 hours prior to using to get the paste come to the room temperature. Well mix the paste using a mixer machine or doing it manually by using spatula.

- Un-finished solder paste must be well seal up again in the airtight jars to prevent contamination and moisture absorption, and put back into the refrigerator.

Contact Now

Please Send Message

${currentPro.title}