EN

Language

All categories

Product ID: 68580655

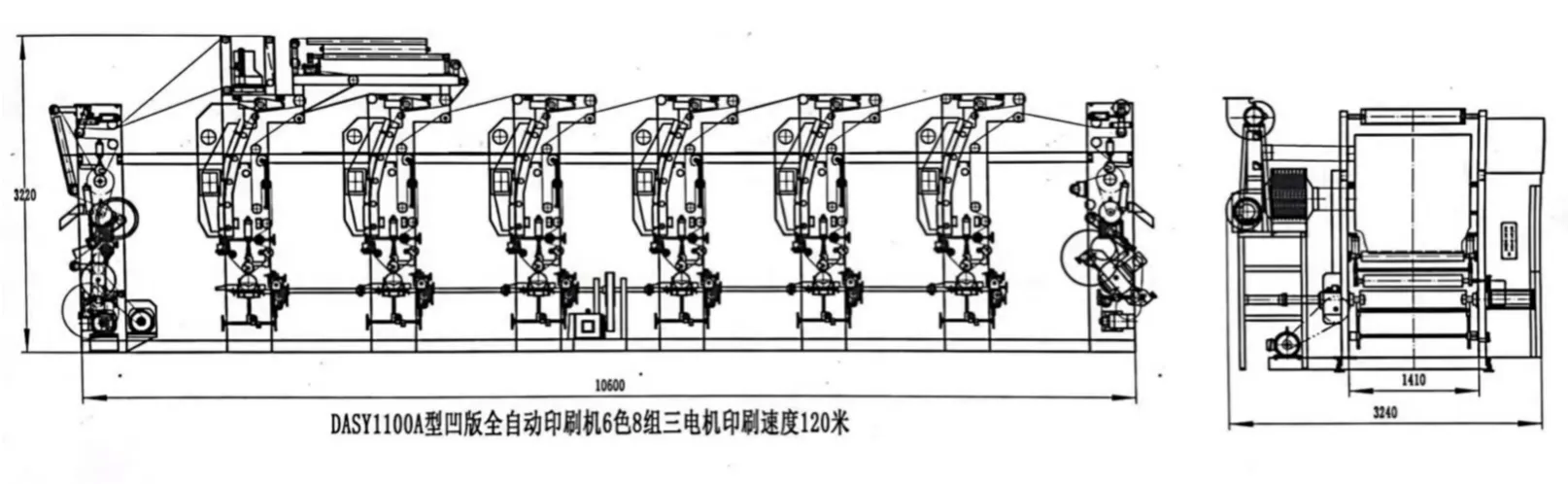

Rotary Gravure Printing Machines for Cigarette and Wallpaper Production

Contact Now

Description

Basic Info.

Model NO.

DSAY-A

Condition

NEW

System Supported

Windowsxp32

After-Sales Service Provided

Overseas Third-Party Support Available

Printing Interface

USB3.0

Applicable Material

Stickers, Textile, Film, Paper, Plastic

Arrangement Position of Color Groups

Combined Gravure Press

Usage

Rigid Packaging Gravure, Flexible Packaging Gravure Printing Machine

Feeding Mode

Web Gravure Printing Machine

Automatic Grade

Semi-Automatic

Color & Page

Double Faced Multi Colors

Structure

Rotary Type Printing Machine

Printing Width

1100mm

Printing Speed

120-130m/Min

Mechanical Speed

130m/Min

Printing Plate Dia

100-350m

Guiding Roller Width

1130mm

Unwinding Dia

570mm

Rewinding Dia

570mm

Transport Package

Wooden Case

Trademark

JINYI

Origin

Whenzhou

HS Code

8443170090

Production Capacity

20 Sets Per Month

Packaging & Delivery

Package Size

1450.00cm * 350.00cm * 310.00cm

Package Gross Weight

9000.000kg

Product Description

Product Description

1.Main parameter:(Based on 8 colors)

1).Printing type | combined rotogravure printing machine |

2).Suitable material | |

BOPP 18-100μm | |

CPP 20-100μm | |

PET 12-100μm | |

NYLON 15-100μm | |

PE (HD&LLD)35-130μm | |

IPP 35-100μm | |

Paper 18-120gsm | |

3).Printing width | 720-1100mm (1100 model) |

4).Mechanical speed | Max130m/min (Printing plate max 150mm) |

5).Printing speed | Max 120m/min (Printing plate max 150mm) |

6).Printing plate dia | 100-350mm |

7).Guiding roller width | 1130mm |

8).Unwinding dia | Max 570mm |

9).Rewinding dia | Max 570mm |

10).Paper core dia | Inner 76mm, outer 92mm. |

11).Unwinding tension | Max 50N.M |

12).Unwind traction tension | 0-25kg (Vector control) |

13).Rewinding tension | Max 40N/m |

14).Rewind traction tension | Max 0-25kg (Vector control) |

15).Registration precision | Vertical ±0.1mm (Computerized) |

16).Pressing printing strength | 235kg |

17).Doctor blade movement | ±5mm |

18).Drying method | Electric heating |

19).Heating power | Each color 28.5kw |

20).Cooling water | 7.68T/h |

21).Main motor | 15KW (Frequency motor) |

22).Power supply | 380V,50Hz,3Phase |

23).Total power | 150KW, actually 90KW (1100 model) |

24).Dimension1100 model | 14500×3500×3100mm |

25).Video inspection system | Kesai ,China .(2000FV) |

Detailed introduction

1. Unwinding

2.Traction tension:

3. Printing Part

Structure:

1).Dual station unwinding turret, 360°inching rotation.

2).Magnetic powder brake manual tension control.

3).The horizontal adjustment is manual

4).Air shaft

5).Auto cutting, pre-transmitting system for roll changes.

Specification:

1).Max roll dia: Φ570mm

2).Roll horizontal adjustment: ±20mm

3).Tension set: Max 50N/m

4).Tension control precision: ±0.1kg

5).Max unwinding width: 1100mm

6).Turret rotating speed: 1r/min

Feature:

1).Unwinding shaft installed on the running supporter making the mechanical resistance smallest and little tension variation.

2).High precision rotation turret inside the wallboard ensures the accurate installation.

3).Air shaft, fast replacement, accurate centering.

4).Magnetic auto tension control two unwinding shaft to keep the tension stable during roll change.

5).It adopts roll change pre-transmitting system during roll change under high speed without stopping machine until the max speed, auto cutting makes the film waste less.

Structure:

1).Dual roller type

2).Pneumatic pressing roller connection and pressure adjustment.

3).Traction steal roller is driven by independent torque motor and triangle belt.

4).Unwinding traction steal roller is controlled by magnetic powder brake and auto tension sensor.

5).Tension floating roller potentiometer can do position inspection, with PLC and frequency converter, it realize close loop controlling.

Specification:

1).Traction roller: Φ125m

2).Pressing roller: Φ110m, PU rubber,A65°~70°

3). Max pressure of pressing roller: 220kg

4). Tension set: Max 25kg

5). Tension precision: ±0.1kg

Feature:

1).Dual roller type ensures the tension stable.

2).Low damping tension floating roller can absorb the tension fluctuation quickly and ensure stable printing.

3).Traction tension is set accurately by precise reducing valve..

4).Driven by triangle belt which is convenient.

Structure:

1) Pneumatic shaftless printing plate installation.

2) Pressing roller is hollow type.

3) The down pressing structure of the pressing roller is swing arm type, move together with guiding roller which could do single adjustment.

4) The doctor blade is pneumatic, driven by independent synchronous motor.

5) The movement of the ink fountain is manual.

6) The driving case is closed type bevel wheel transmission case, when the power transmitted to the printing plate, it is pneumatic clutch control.

7) Automatic computerized registration, compensating roller adopts vertical movement type, the precise lead screw is transmitted by registration synchronous motor.

Specification:

1) Printing plate length:720~1120mm(1100 model)

2) Pressing roller: Φ120mm PU rubber A65°~70°

3) Max pressing strength: 235kg

4) Doctor blade movement: ±5mm

5) Max ink-dipping depth: 40mm

6) Doctor blade pressure: 10-100kg

Feature:

1).Doctor blade adjusted in 3 direction can make the best angle.

2).Pneumatic clamping device of shaftless plate installation can improve the efficiency of plate replacement.

3).The linkage of pressing roller and guiding roller prevent the film from stretching and ensure the registration accuracy.

4).Computerized registration make the printing accuracy higher and improve production efficiency and save labor.

5).Left and right floating roller adopts lead screw, little space making reset accurate.

6).Computer registration makes the printing more accurate, improve production efficiency and save labor.

4. Drying part

5. Cooling part

6. Rewinding

Structure:

1) Independent drying and suction exhausting system, air circulated.

2) Fully closed oven.

3) Electric heating

4) Intelligent continual constant temperature controlling

5) Waste air eliminating tunnel

6) Longer oven of last unit

Specification:

1) Max temperature: 60℃

2) The material length in the oven: 1212mm

3) Wind mouth: 9 pieces

4) Returning hot wind use rate: 0~50%

5) Max temperature controlling precision: ±2℃

6) Max supply air rate: 2300m3/h

7) Blower power:

Intake air blower: 3kw (Each color)

Suction blower: 1.1kw (Each color)

Feature:

1) Circulated air save energy.

2) Multiple path drying prevent the film from blistering.

3) Each color auto constant temperature control, convenient and accurate.

4) Fast blowing speed and high rate of flowing make the film dried under high blowing speed and low temperature.

5) Oven is fully closed which is convenient for film going.

6) Minus pressure inside the oven keep hot air inside.

7) Outside oven increase the amount of blowing air to ensure the drying.

8) Longer oven of last unit can prevent the last color adhesive to the printing cylinder when the color cover the whole cylinder.

Structure:

1) Air cooling and water cooling

2) Water cooling roller is running type, the cooling water flowing back when the roller is full of water. Air cooling adopts centrifugal blower.

3) Water cooling roller touches the surface of the printing material.

Specification:

1) Centrifugal blower 0.25kw

2) Water cooling roller Φ150mm

3) Water amount 7.68t/h

Feature:

1) Easy structure reduce the resistance of film.

2) It can cool the material completely, and get the material to its original state which is better for precise registration.

3) Big diameter water cooling roller ensures the cooling after the film is dried.

Structure

1) Dual station turret, inching rotation.

2) Two rewinding shaft is transmitted by two torque motor.

3) Rewinding air shaft

4) The horizontal adjustment of the roll is manual

5) Roll change pre-transmitting system

6) It can alarm automatically when it reaches to the set length.

7) Auto splicing and cutting.

Specification:

1) Max roll dia: Φ570mm

2) Roll horizontal adjustment ±20mm

3) Rewinding motor(2 set) Max 40N/m

4) Turret rotating speed 1r/min

5) Tension set 40N/m

6) Tension decelerating 0-100%

Feature:

1) Rewinding tension adjustment prevent the film from being irregular.

2) Air shaft, convenient replacing and accurate centering.

3) It adopts roll change pre-transmitting system during roll change under high speed without stopping machine until the max speed and angel. Auto cutting reduces film waste.

4) Rewinding tension adjustment can prevent the film from being irregular.

7. Frame

8. Main transmission part

9. Auto tension

Structure:

1)The wall board is made of high strength low stress combined alloy cast iron.

2) The guiding roller is hollow.

3) Video inspection device.

Specification:

1) Thickness of the wall board: 70mm

2) Distance between two printing unit: 1m

3) Guiding roller: 56mm76mm100mm

4) Guiding roller length: 1130mm

5) Distance between of curving line of guiding roller: 36mm

Feature:

1) Combined wallboard with high stability.

2) Each guiding roller has line shape to prevent film from slipping during running.

3) Video inspection device let us see printing result clearly and ensure the registration accuracy.

Structure:

1) The main inverter motor sends the transmission to each color and drive the printing plate roller rotate by main transmission roller and several couple shaft and gear case.

2) Driven by triangle belt

3) The connecting point with gear case and each transmission shaft is flexible connection.

Specification:

1) Inverter motor power: 15kw

2) Transmission shaft dia: Φ40mm

3) Coupling Flexible type

Feature:

1) Full load start under low speed

2) Transmission is accurate and even

1) 3 motor closed loop tension system, PLC and man-machine centralized control

10. Lighting system

1) Explosion-proof lamp

11. Photo eye registration

1) Vertical auto registration system adopts photo eye registration system which is made in china.

Main component brands and models

Main equipment list:

1. PLC | Siemens,Germany |

2. Man machine | Hitech, Taiwan |

3.Temperature controller | Keqiang, China |

4.Pneumatic parts | Airtac,Taiwan |

5.Main bearing | NSK,Japan |

6. Magnetic powder brake | Huangguang,China |

7. Rewinding traction frequency motor | Siemens ,Germany |

8. Low damping and precision cylinder | Fujikura,Japan |

9. Precise reducing valve | SMC |

10. Precise potentiometer | Saia-burgess |

11.Main motor | Siemens,Germany |

8.Rewinding torque motor 40N/m | Weili,China |

9.Frequency converter | Yaskawa ,Japan(or Inovance ,China) |

10.Auto register system | Kesai,China |

11.Video inspection system | Kesai,China |

12.Photo eye | Kesai,China |

13.Auto tension controller | Wennew,china |

14.Low voltage electrics | Chint, China |

15.Switch | Shinuo,China |

16.Centrifugal blowers | China |

17.Synchronous motor | Xinjiefei,China |

18.Explosion-proof lamp | Huapu,China |

Customer need to prepare:

1.380V 50Hz 3 phase four line power;

2. Basic treatment;

3. Equipment for installation;

Notice: Our company preserve the rights to the above specification and has the rights of final explanation to the configuration modification without advanced notice.

Optional devices

Spare Parts Listwith machine ( 8colors) |

Name and description | Quantity | Notice |

DASY-1100A model rotogravure printing machine | 1 set | 1.Extra add one big meter display 2.Static brush 10pieces |

Operational manual | 1 piece | |

Main motor | 1 set | |

Pneumatic ink pump | 8pieces | |

600mm rubber roller | 8pieces | |

800mm rubber roller | 8pieces | |

1100mm rubber roller | 8pieces | |

600mm general ink roller | 8pieces | |

800mm general ink roller | 8pieces | |

1100mm general ink roller | 8pieces | |

Ink tray | 8pieces | |

10 inch adjustable wrench | 1 pieces | |

Soft and hard scraper | each 8 pieces | |

Inner six-angle wrench | 1 piece | |

8 inch line shape screwdriver | 1 piece | |

17~14 open mouth wrench | 1 piece | |

8~10 open mouth wrench | 1 piece | |

17~19 wrench plum blossom | 1 piece | |

22~24 open mouth wrenc | 1 piece |

FAQ

Pre-sales issues

01. How to get in touch with us?

Call us directly +86 15258698252 (Ms. Jolie )

Direct to the company: WANGNAN ROAD, JIELUTOU VILLAGE, SHANGWANG STREET, RUIAN, WENZHOU, ZHEJIANG, CHINA

01. How to get in touch with us?

Call us directly +86 15258698252 (Ms. Jolie )

Direct to the company: WANGNAN ROAD, JIELUTOU VILLAGE, SHANGWANG STREET, RUIAN, WENZHOU, ZHEJIANG, CHINA

03. How to recommend products?

We have nearly 14 products in four series. We can also provide non-standard equipment production and new product development services according to customer requirements. According to the customer's requirements to be produced, the purpose of the product to be purchased, the environment, the purchase volume and other related conditions, we will recommend several cost-effective products for the customer to choose.

We have nearly 14 products in four series. We can also provide non-standard equipment production and new product development services according to customer requirements. According to the customer's requirements to be produced, the purpose of the product to be purchased, the environment, the purchase volume and other related conditions, we will recommend several cost-effective products for the customer to choose.

02. How to answer technical guidance?

For some customers who need non-standard equipment, we will communicate with the company's relevant technical personnel according to the customer's specific requirements, taking into account the technical feasibility and production costs, and give customers solutions.

For some customers who need non-standard equipment, we will communicate with the company's relevant technical personnel according to the customer's specific requirements, taking into account the technical feasibility and production costs, and give customers solutions.

04. How to make a quotation?

Based on our company's research and development costs, production costs and customer purchases, we conduct calculations to determine the price of the product.

Based on our company's research and development costs, production costs and customer purchases, we conduct calculations to determine the price of the product.

Problems in sale

01. About payment

After signing the contract, 30% of the total payment will be paid in advance, and the factory will accept the payment and pay the full amount of the machine for delivery.

01. About payment

After signing the contract, 30% of the total payment will be paid in advance, and the factory will accept the payment and pay the full amount of the machine for delivery.

03. Order tracking

After the customer places an order, our company will send professional personnel to track the order and regularly report the production progress to the customer. Customers can check the order status on the official website (delivery query).

After the customer places an order, our company will send professional personnel to track the order and regularly report the production progress to the customer. Customers can check the order status on the official website (delivery query).

05. Product packaging

Before the product is shipped, it will be packed in a strict vacuum plus bottom tray (wooden tray or steel tray)

Before the product is shipped, it will be packed in a strict vacuum plus bottom tray (wooden tray or steel tray)

02. About delivery time

About 45 working days after receiving the deposit (non-standard machine), the factory will re-decide whether to change the delivery date when the order is confirmed. The standard machine is generally within 30 working days after receiving the deposit

04. Product testing

During the production process, our company will adopt strict inspection process to ensure product quality. Through internal inspection, we ensure that the components produced by our company meet the technical requirements; through external inspection, we ensure that the components produced by our company are not subject to quality problems; and then pass the whole machine inspection to ensure that the mechanical equipment meets the technical production requirements .

06. Product Transportation

Products are generally shipped from Ningbo Port, China to the destination port by sea.

After sales question

01. Shelf life/warranty period of the product

The product warranty period is generally one year, and our company provides lifetime maintenance services. If the machine has quality problems, our company will help the customer to solve it through the following ways: a. Send spare parts to the customer. b. Remotely assist customers in maintenance. c. Notify our agent company to send personnel to the customer's factory for maintenance. d. Our company directly dispatches relevant personnel to the customer's factory for maintenance.

03. About machine maintenance

We will contact customers on a regular basis on how to maintain and maintain the machine. For domestic customers, we will have a master to provide on-site service.

01. Shelf life/warranty period of the product

The product warranty period is generally one year, and our company provides lifetime maintenance services. If the machine has quality problems, our company will help the customer to solve it through the following ways: a. Send spare parts to the customer. b. Remotely assist customers in maintenance. c. Notify our agent company to send personnel to the customer's factory for maintenance. d. Our company directly dispatches relevant personnel to the customer's factory for maintenance.

03. About machine maintenance

We will contact customers on a regular basis on how to maintain and maintain the machine. For domestic customers, we will have a master to provide on-site service.

02. About transportation damage

In the process of product transportation, if product damage occurs, it is determined that our product packaging and reinforcement work is not in place, and our company will bear the corresponding losses.

04. Problems during use

If there is any problem in the process of using the product, the customer can directly call or send an email to our after-sales department (24-hour hotline). The personnel of our department will respond immediately and make a decision on the response measures within 24 hours.

Wenzhou Jinyi Machinery Co., Ltd

Wenzhou JINYI Machinery Co., Ltd is specialized in producing plastic soft packing and paper printing equipment. We have applied ourselves to the printing and packing work of research, development and production for a long time, we take advantage of processing superiority in wenzhou city, absorb other's good aspects to research, improve and perfect our products to make them advanced and reliable characters, our product have excellent quality and price to occupy the market.

Our company mainly produce the products as following: any grade of rotogravure printing machine, slitting machine, laminating machine and plastic bag making machine, we also design and produce the special machine for our customer according to their special requirements.

We look forward to make friends with much more people with lofty ideals, and also listen to the comments and suggestions from old and new customers.

We will go forward hand in hand to build our glorious futu.

Our company mainly produce the products as following: any grade of rotogravure printing machine, slitting machine, laminating machine and plastic bag making machine, we also design and produce the special machine for our customer according to their special requirements.

We look forward to make friends with much more people with lofty ideals, and also listen to the comments and suggestions from old and new customers.

We will go forward hand in hand to build our glorious futu.

Why Choose Us?

OEM/ODM capabilities

Competitive pricing & bulk discounts

Fast shipping & customs clearance support

Turnkey project solutions

Competitive pricing & bulk discounts

Fast shipping & customs clearance support

Turnkey project solutions

Other Products

Printing Machine

Flim Blowing Machine

Dry Laminlating Machine

Slitting Machine

Auto Online Inspecting Rewinding Machine

Seaming Machine

Bag Making Machine

Flim Blowing Machine

Dry Laminlating Machine

Slitting Machine

Auto Online Inspecting Rewinding Machine

Seaming Machine

Bag Making Machine

Contact Now

Please Send Message

${currentPro.title}