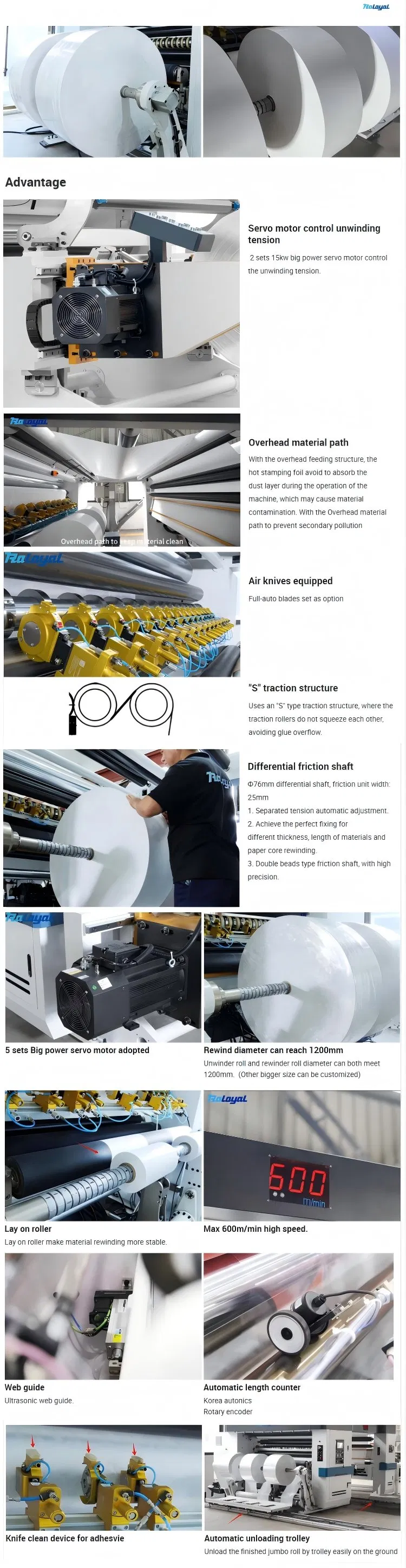

High-Speed Thick PVC Film Slitting and Rewinding Machine

Description

Overview

Basic Info.

- Model NO. HCH4

- Application Machinery & Hardware

- Type High-Speed Slitting Machine

- Work Method Shear Knife Slitting

- Structure Cutting Part

- Packaging Wooden Pallet

- Classification Slitting Machine for Paper, Laminated Material

- Applicable Process Process Materials

- Useful Substrates Thicker Flexible Film, Computer Security Label

- Packaging Material Wood

- Use Electric, Medicine, Optical, Advertisement

- Speed 600 M/Min

- Min Slitting Width 30mm

- Precision 0.03 mm

- Driving Method 5 Servo Motors

- Unwinding Roll Diameter 1200mm

- Rewinding Roll Diameter 1200mm

- Control System PLC

- Unloading System Automatic Shaft-Less Loading

- Delivery Time 60 Work Days

- Certification CE, TUV

- Transport Package Pallet

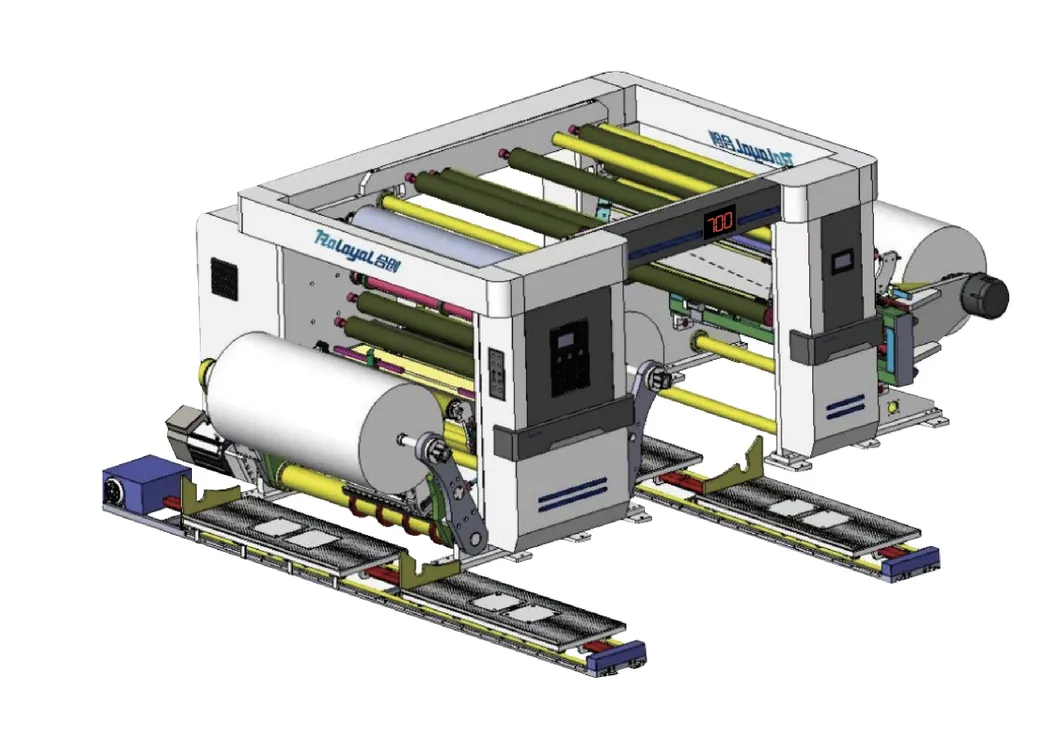

- Specification 4000*2880*2250 mm

- Trademark RALOYAL

- Origin China

- HS Code 8441100000

- Production Capacity 100 Sets/Year

Packaging & Delivery

- Package Size 1.00cm * 1.00cm * 1.00cm

- Package Gross Weight 1.000kg

Product Description

Technical Parameter

| Model | HCH4-1300 | HCH4-1600 | HCH4-2200 |

|---|---|---|---|

| Slitting effective width | 30-1300mm | 30-1600mm | 30-2200mm |

| Slitting speed | 600m/min | 600m/min | 600m/min |

| Unwinding roll diameter | φ1200mm | φ1200mm | φ1200mm |

| Rewinding roll diameter | 2*φ1200mm | 2*φ1200mm | 2*φ1200mm |

| Precision | ±0.03mm | ±0.03mm | ±0.03mm |

| Machine weight | 6400kg | 6400kg | 6400kg |

| Machine overall dimension | 4500*3600*2000 mm | 4500*3600*2000 mm | 4500*3600*2000 mm |

Use: This machine is with special design, satisfying the demands of jumbo roll, high speed, and huge loading weight. Can be equipped with high-quality adhesive label and paper etc material slitting and rewinding.

Differences: Individual shaft-less loading, automatic unloading, overhead material path, double "S" structure, semi-auto blade set, 5 sets servo motors driven, etc.

Case Sharing

Application Scenario

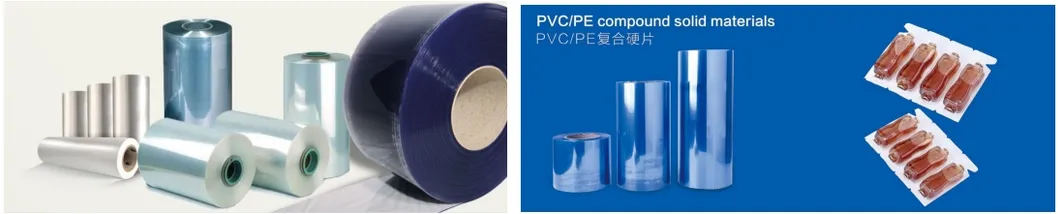

BOPP, OPP, PP, PVC, PET, LDPE, PI, optical film, etc. film

PVC solid materials and PE films

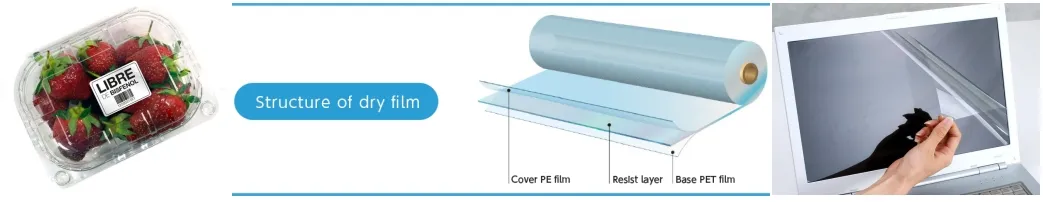

PET container

Dry film

Electronic protective film

Why Choose Us

------R&D Loyal engineers focus on the innovation of the paper straw forming continuously. We combine powerful construction and aesthetic characteristic while maintaining the highest standard of quality.

------QA In order to supply products of high consistently high quality and reliability, Loyal staff strengthens Quality Assurance protocols and procedures as important part of overall quality, safety management.

------Detail Care about every detail to improve our dear customers' operation efficiency and convenience.

------After-sale service Loyal team will respond to clients' inquiries or questions within 24 hours.

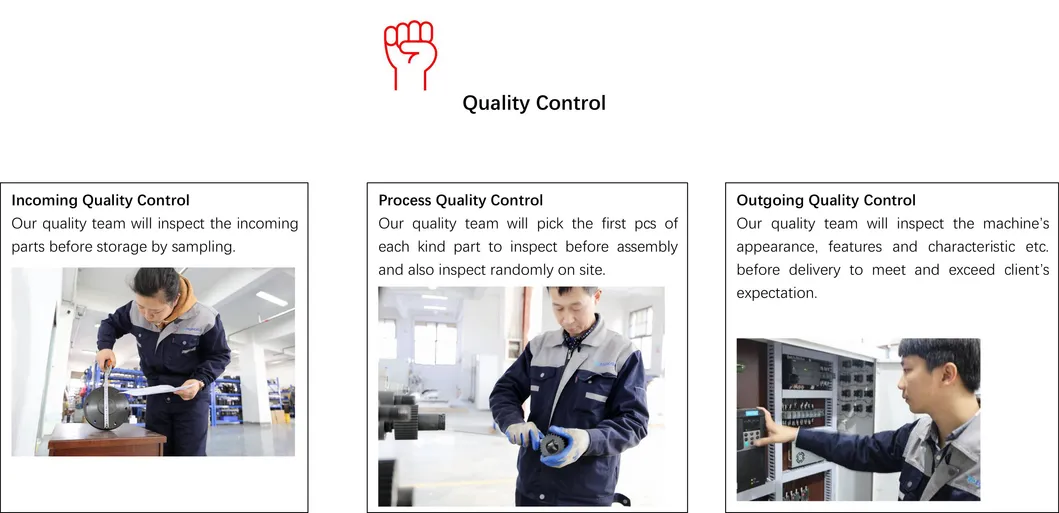

1. Quality Control

2. Our Service

3. Certification

3. Packaging & Shipping

Customer Feedback

${currentPro.title}