Automatic Aluminum Foil Baking Paper Silicon Paper Slitting Cutting Rewinding Slitter Rewinder Machine **Title:** **Slitting Cutting Rewinding Machine for Aluminum Foil, Baking Paper & Silicon Paper**

Description

Basic Info

| Model NO. | SDA500 |

|---|---|

| Application | Machinery & Hardware, Food, Commodity |

| Type | High Speed Rewinding Machine |

| Work Method | High Speed Rewinding Machine |

| Structure | Cutting Part |

| Packaging | Case |

| Classification | Cutting and Rewinding |

| Applicable Process | Final Inspection |

| Suitable Substrates | Baking Paper Foil |

| Packaging Material | Paper Plastic |

| Width of Material | 200-450mm |

| Diameter of Un-Winder Roll | 700mm Max |

| Diameter of Re-Winder Roll | 90mm / Max. Length 300m |

| Core Size of Re-Wind | 30mm, 35mm or 38mm Other Size Can Request |

| Minimum Length of Rewind | 1 meter |

| Max. Speed | 550m/Min |

| Main Motor | 4kw |

| Change Motor and Gear Reducer | 750W |

| Sticker Motor | 750W |

| Weight | 2000kg |

| Unwind and Rewind Tension | Automatic Tension |

| Invertor | Delta Taiwan |

| Transport Package | Wooden Box |

| Specification | 2500*2000*1900mm |

| Trademark | Suntop |

| Origin | China |

| HS Code | 84778000 |

| Production Capacity | 20 Sets/ Month |

Packaging & Delivery

| Package Size | 2500.00cm * 2100.00cm * 1900.00cm |

|---|---|

| Package Gross Weight | 2000.000kg |

Product Description

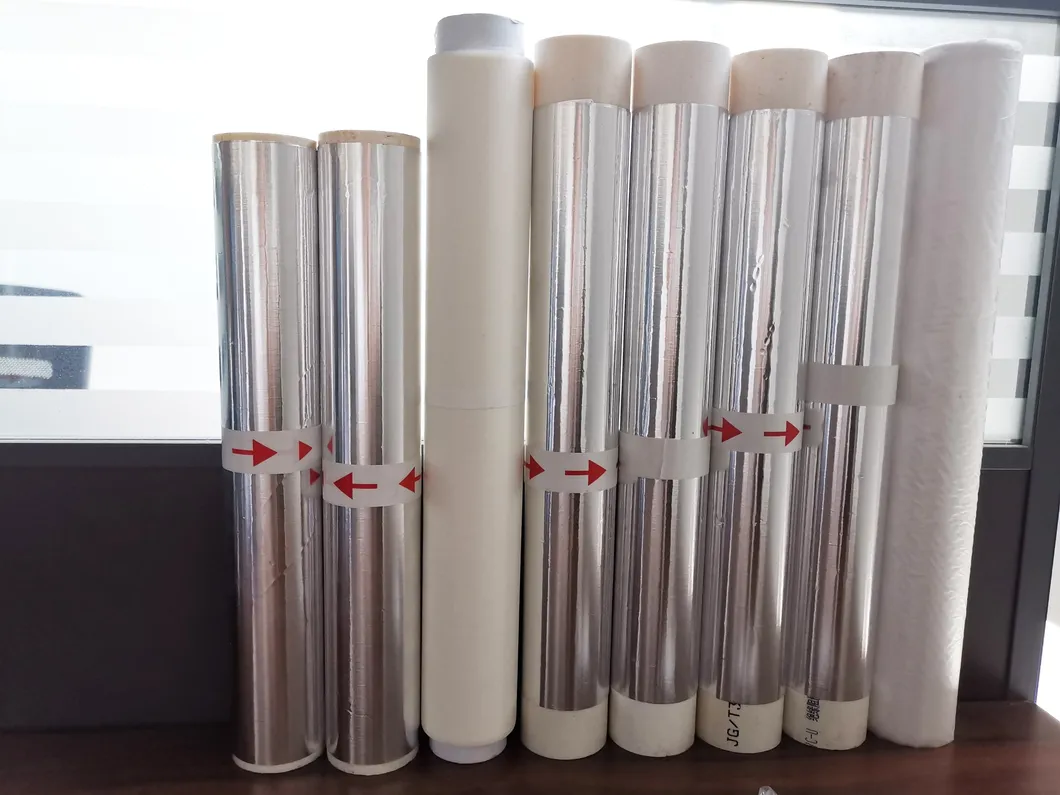

Introduction: Automatic aluminum foil and baking paper rewinding machine. Automatic aluminum foil and baking paper rewinding machine, it is controlled by PLC microcomputer, adopts 4 motors. The meter is measured by a high-precision encoder. Can rewind from 1m to maximum 300m. 6 shafts automatic changes without stop, automatic spraying hot melt glue and automatic labeling. With high speed from 15 rolls to 40 rolls per minute.

Specification

| Max Mechanical Speed | 550m/min |

|---|---|

| DIAMETER OF UNWINDING | 750MM |

| DIAMETER OF REWINDING | 90MM |

| Main motor | 4kw |

| Air pressure | 0.5Mpa |

| change motor and gear reducer | Servo motor |

| Sticker motor | Servo motor |

| Invertor | Delta , Taiwan |

| PLC | Schneider, France |

| Touch screen | Schneider, France |

| Hotmelt glue machine | China famous brand |

| Unwind and rewind tension | Automatic tension |

| Auto count meter | By encoder |

| Material finish function | Automatic machine stop |

| Weight | 2000kg |

| Installing dimension (LXWXH) | 3500*1800*2100mm |

FAQ

- Q1: You are trade company or factory? We are Manufacturer.

- Q2: How can we make sure about the machine quality after placing the order? Before delivery, we will test machine and send you the pictures with videos for you to check the machine quality.

- Q3: Are we still need to install the machine after we got? We will adjust the machine before we delivery to you, also we will send you video and manual to teach you how to use the machine.

- Q4: Can I put my LOGO/brand on the machines and finish products? Yes, Sure, Just send us your artwork.

- Q5: Is engineer available to serve oversea? Yes, we have the oversea service. But the travel fee is responsible by you. In order to save your cost, we will send you videos of full details machine installation and assist you till the end.

- Q6: Can you explain me the whole transaction process? 1. Sign the Contact 2. Arrange deposit to confirm order 3. Factory arrange production 4. Testing & detecting the machine before shipping 5. Inspected by customer or third agency through online or site test. 6. Arrange the balance payment before shipment.

- Q7: How about after-sales support? 1. Machine installation and operation videos are available for reference. 2. Each machine set includes extra spares for replacement. 3. We have professional after-sale team to follow about the service. 4. If any help need about machine maintenance, we can have a video call to support.

- Q8: How can I contact you? Please feel free to send us inquiry or by email, Phone, Wechat, Whatsapp.

- Q9: How to visit your company? Our factory is located in Zhejiang Province. Please advise the visiting date in advance, we can pick up you from Airport or Railway station.

Contact us

If you want get more details, or can not find out what are you looking for, please feel free to contact me, I will do my best for you.

${currentPro.title}