Automatic Cable Stripping and Copper Recycling Machine

Description

Overview

Model NO. MCT-800

Cutter Material High-Speed Steel, SKD-11

Drive Electric, Electric

Object Metal, Copper Aluminum Electric Wire

Type Impact Crusher, Crusher Separating Machinery

Finished Surface Outer Surface Process

Compressive Strength (for Crushing) >300MPa

Tongs' Features Adjustable Tongs

After-Sales Service 24 Hours Online

Warranty 1 Year

Principle Air Separation

Name Automatic Cable Stripping Machine Scrap Copper

Power 57kw

Output Size <3mm

Weight 4000kg

Raw Material Waste Cable Wire

Final Product Pure Copper

Application Scrap Cables Copper Wire

Advantage High Separator Rate 96-99.99%

Used for Recycling Wasted Electric Wires

Separation Method Electrostatic Separation

Suitable Material Waste Computer Board

Transport Package Standard Export Wooden Case Packing or Container

Specification 4000*2000*2400mm

Trademark MC

Origin Zhengzhou

HS Code 8479820090

Production Capacity 500-600kg/H

Product Description

Automatic Cable Stripping Machine Scrap Copper Wire Recycling Sorting Machine: Copper wire granulator machine adopts advanced design, reasonable structure and reliable operation. This production line can not only deal with the coarse thread that ordinary crusher can deal with, but also has a good separation effect to the very fine thread. It is dry type structure, which includes crushing system, conveying system, dust removal system, gravity separation system, tailings screening system and control system.

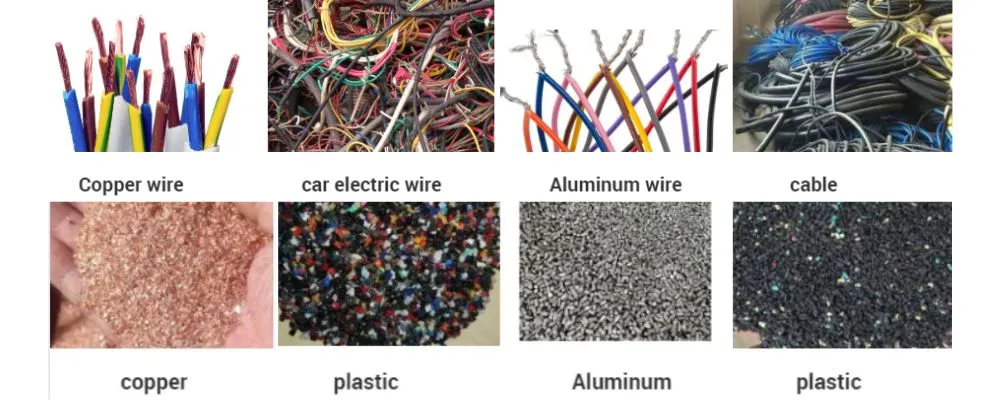

Scarp of application waste copper wires crushing machine: Crushing and sorting of various waste wires, sorting of broken copper, aluminum, and iron of copper aluminum radiator.

Cable Recycling Plant Features

- Large handling capacity, suitable for large scale production.

- Manual feeding material for one time, multiple machines combined for automatic separation.

- Adopting PLC to control the whole system, having stable performance.

- The copper recycling rate can reach 99%.

- The plant adopts air and vibration separation, no water pollution.

- Equipped with dust collector, no dust pollution.

- The voltage can be customized according to your requirements.

Product Parameters

| Model | MCT-400 | MCT-600 | MCT-800 | MCT-1000 |

|---|---|---|---|---|

| Output | 100-150kg/h | 200-300kg/h | 500-600kg/h | 800-1000kg/h |

| Total Power | 27kw | 42.25kw | 57kw | 87kw |

| Feed diameter | 1-20mm | 1-20mm | 1-20mm | 1-20mm |

| Output size | <3mm | <3mm | <3mm | <3mm |

| Physical dimension | 3*1.8*2 m | 3.5*2*2.4 m | 4*2*2.4 m | 4.8*2.5*2.4 m |

| Weight | 2000kg | 3000kg | 4000kg | 5000kg |

Detailed Photos

Each step is controlled by the PLC program, one key to start and stop. The video of the operation interface shows the working status of important components, and intelligently displays equipment failures. It is easy to operate and maintain, and the separation purity can reach 99%. The single core diameter is ≥0.2mm. Different types of equipment have different input capacities, and the capacity range can range from about 200 to 1000 kg/hour.

Packaging & Shipping

Copper wire recycling equipment type 400 is packed in wooden cases, and type 600 or more is put into containers

${currentPro.title}